Composite ceramic rod for casting forming of hollow single crystal blade top cover hole, manufacturing method and application

A single crystal blade, casting molding technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of extremely high temperature resistance performance, difficult removal, insufficient strength of quartz glass rods, etc., and achieve excellent high temperature The effect of strength, good fit and excellent releasability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

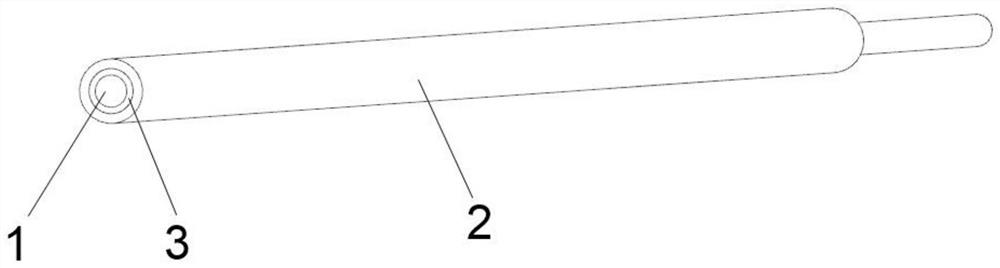

[0028] Such as figure 1 As shown, the composite ceramic rod for casting molding of the top cover hole of the hollow single crystal blade includes a core, a transition layer and an outer layer, the core is a ceramic rod, and the transition layer is a ceramic core matrix wrapped outside the core material, the outer layer is SiO2 material wrapped on the outside of the transition layer, the core of the composite ceramic rod is an embedded alumina rod or zirconia rod, which has excellent high temperature strength, and the outer layer is a quartz glass tube, which has excellent reliability Removal.

[0029] The ceramic rods are high-purity Al2O3 or Zr2O3 ceramic rods.

[0030] The ceramic core matrix material is consistent with the material used for casting and molding the hollow single crystal blade.

[0031] The ceramic core matrix material is SiO2-AL2O3 mixed ceramic slurry or SiO2-Zr2O3 mixed ceramic slurry.

Embodiment 2

[0033] A method for manufacturing a composite ceramic rod for casting molding of a hollow single crystal blade top cover hole, comprising the following steps:

[0034] (1) Put the ceramic rod into a size-matched quartz glass tube;

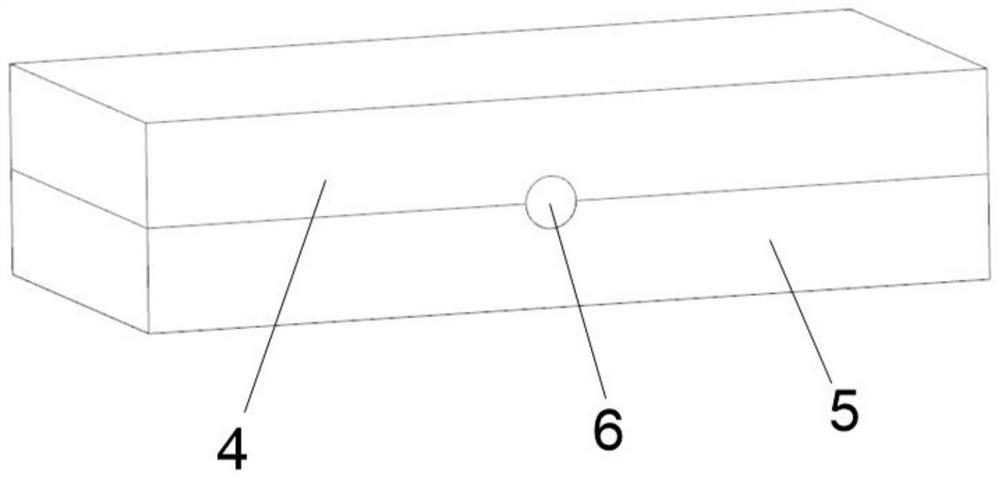

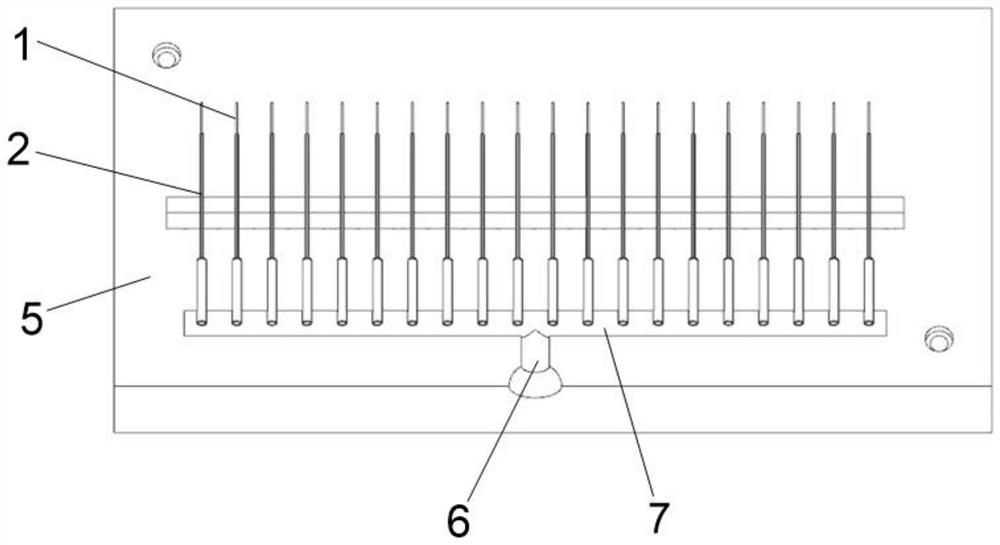

[0035] (2) if Figure 2-5 As shown, the quartz glass tube inserted with the ceramic rod obtained in step (1) is put into a pre-designed mold, and the ceramic core matrix slurry is injected into the ceramic rod and the quartz glass tube through a ceramic slurry injection machine. In the gap, a composite material embryo body with the outer layer of quartz glass tube, the interlayer of ceramic core matrix slurry, and the core of ceramic rod is made. The composite material embryo body has a transition layer ceramic core matrix slurry injection remaining head, such as Figure 6 shown;

[0036] (3) putting the composite material green body obtained in the step (2) into a ceramic core sintering furnace, and sintering molding according to the sintering ...

Embodiment 3

[0042] An application of a method for manufacturing a composite ceramic rod for casting molding of a hollow single crystal blade top cover hole, comprising the following steps:

[0043] The mold in step (2) is integrally designed with the ceramic core wet blank mold. When pressing the ceramic core wet blank, the quartz glass tube, the ceramic core matrix slurry and the high-purity ceramic rod are pressed on the ceramic core wet blank. In the process, the composite ceramic core wet blank is obtained, put into a high-temperature sintering furnace for sintering and forming, and an integrated ceramic core for casting with a composite ceramic rod is made.

[0044] In the present invention, the composite structure is formed into an embryo body through a mold, and is sintered at a high temperature to form a compact whole, and at the same time, it has both Al 2 o 3 or Zr 2 o 3 The high temperature strength and SiO 2 Easy removal, and due to the existence of the intermediate transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com