Cleaning method for crucible assembly of electron beam evaporation table

A technology of electron beam evaporation and cleaning method, which is applied in the cleaning field of crucible components of electron beam evaporation table, can solve the problems of cumbersome operation, incomplete cleaning, and high cost, and achieve the effect of fast and effective method, convenient cleaning and removal operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

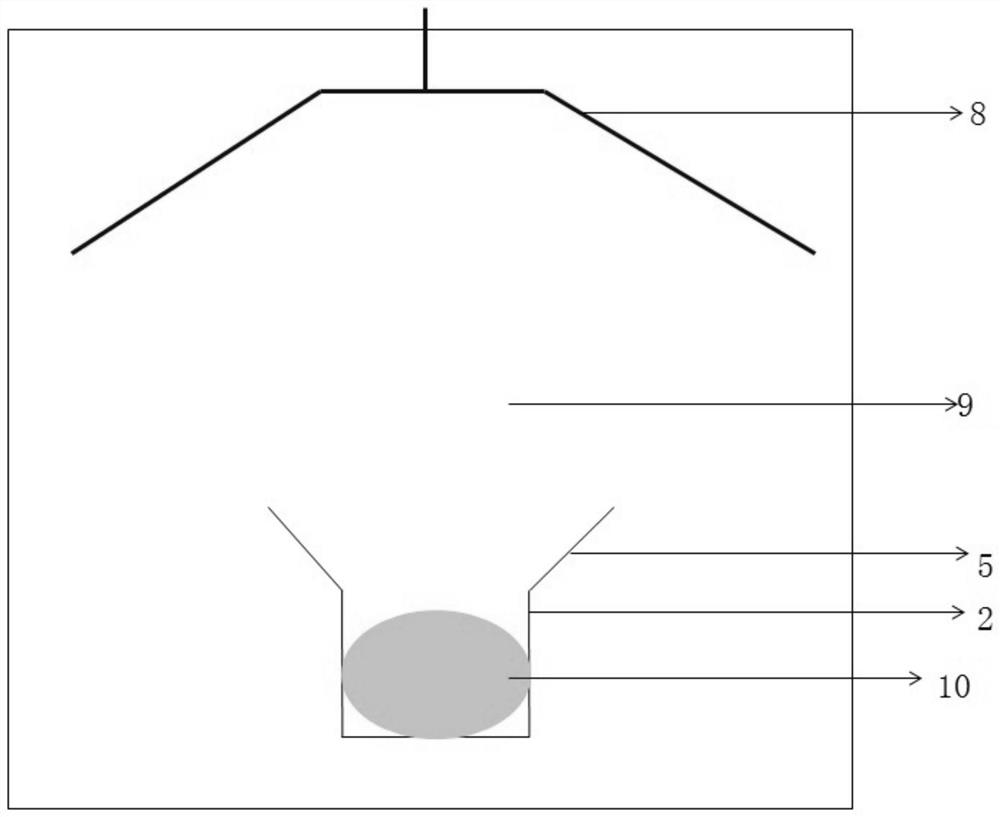

[0033] This embodiment provides a method for cleaning the crucible assembly of an electron beam evaporation table, and the operation steps are as follows:

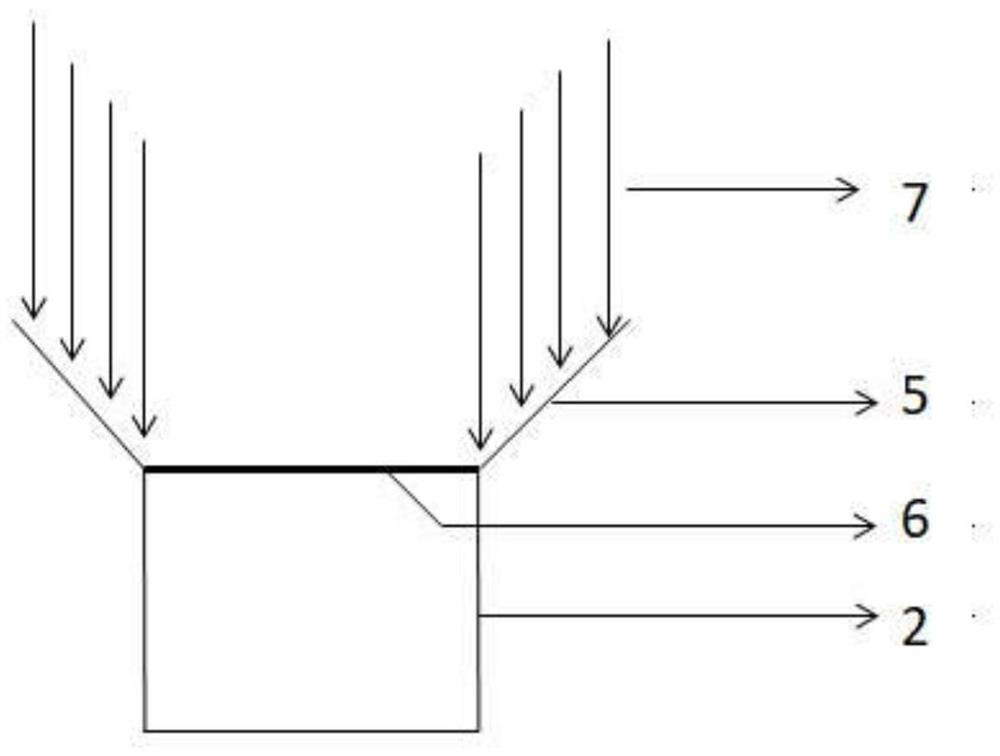

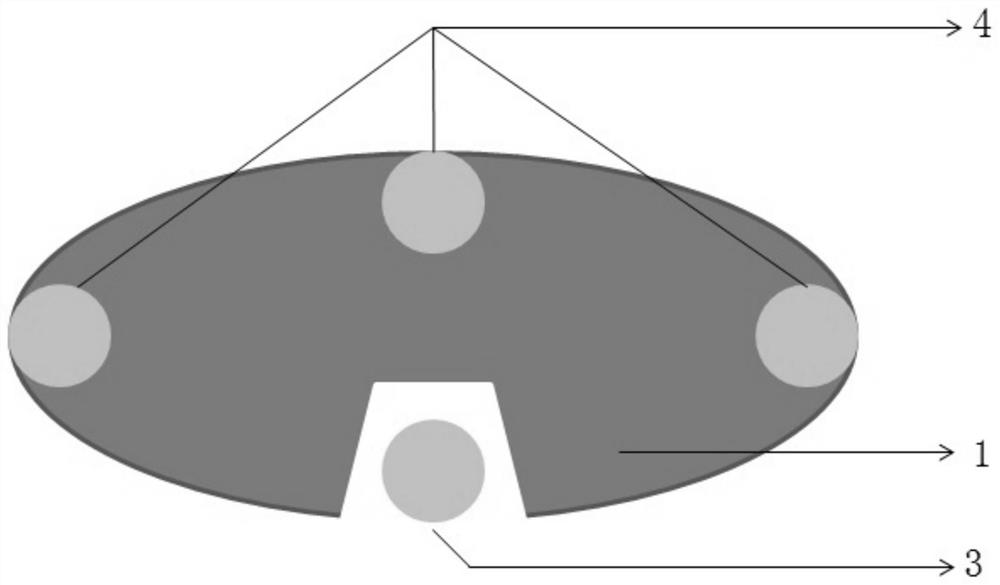

[0034] (1) Coating production: place a baffle plate 6 above the crucible 3, use boron nitride spray to spray a layer of boron nitride above the baffle plate, and the spraying direction 7 is as follows: figure 2 As shown, the boron nitride spray is evenly distributed on the side wall of the crucible, and the baffle plate 6 is removed after the spraying is completed;

[0035] (2) Crucible use: place a metal evaporation source in the crucible sprayed with boron nitride spray coating, and evaporate metal;

[0036] (3) Crucible cleaning: use tools to scrape off the metal layer on the side wall 5 of the crucible to complete the crucible cleaning.

[0037] The baffle plate 6 described in the step (1) is a circular baffle plate, and the diameter of the baffle plate is larger than the diameter of the crucible, so as to ensure tha...

Embodiment 2

[0043] A method for cleaning the crucible assembly of an electron beam evaporation table, the operation steps are as described in Example 1, the difference is that the thickness of the boron nitride spray coating in step (1) is 300 μm.

[0044] The tool used in step (3) is a blade.

[0045] After cleaning by the cleaning method of this embodiment, the residual amount of the metal layer on the side wall of the crucible is 0.

Embodiment 3

[0047]A method for cleaning the crucible assembly of an electron beam evaporation table, the operation steps are as described in Example 1, the difference is that the boron nitride spray described in step (1) is a BN-Q type spray, and BN-Q Type spray is an anti-bonding protective material, and its boron nitride content is more than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com