Method for reducing additive manufacturing cracks of nickel-based superalloy and nickel-based superalloy

A technology of nickel-based superalloy and additive manufacturing, which is applied in the field of nickel-based superalloy to reduce cracks in nickel-based superalloy additive manufacturing, and can solve the problems of easy deformation, limited production and application of laser additive manufacturing technology, and high residue Stress and other problems, to achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

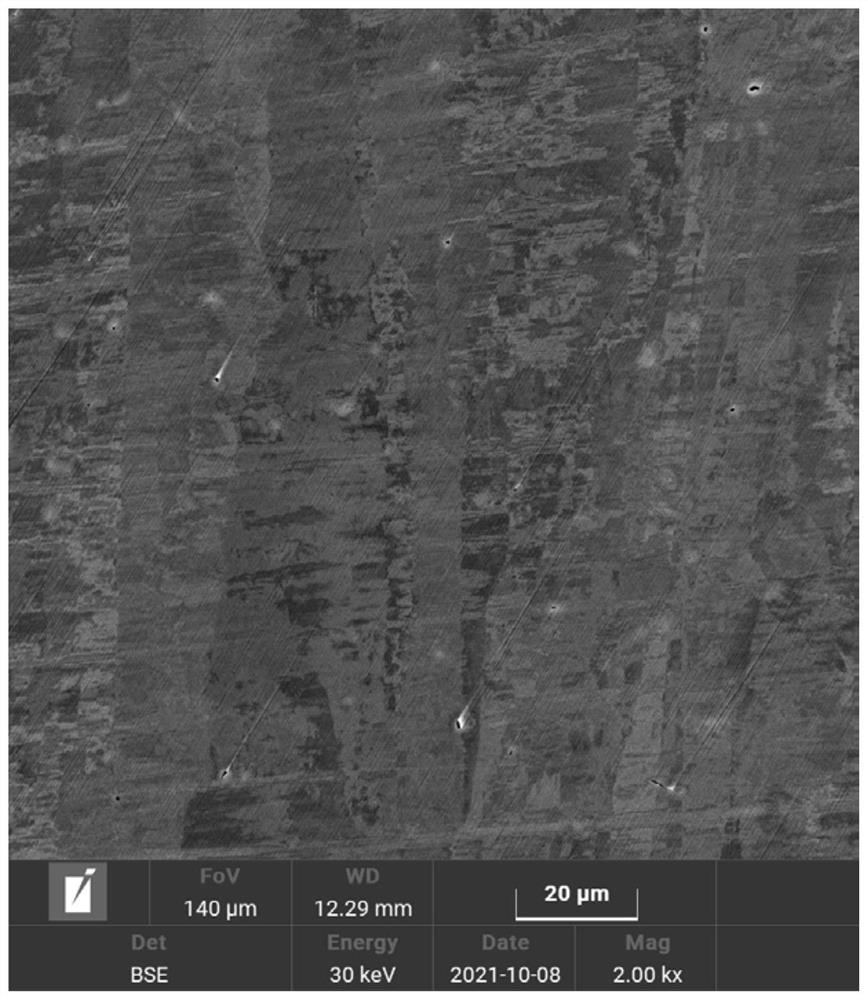

[0028] (1) In Example 1, the following IN718 nickel-based superalloy is used, and the mass fraction of 0.5% rare earth element Re is added, and the mass percentage of IN718 nickel-based superalloy is: Cr: 20%, Fe: 12%, Mo: 3%, Nb: 5%, Co: 18%, C: 0.05%, Mn: 0.02%, Si: 0.2%, Cu: 0.02%, Al: 0.5%, Ti: 1%, B: 0.005%, and the balance is Ni.

[0029] (2) The primary particle size of IN718 is fine enough. In order to reduce the total grinding time, the powder mixture is prepared in two stages. The first stage is mechanical alloying, the weight ratio of IN718 nickel-based superalloy and Re powder is 1:1; in the second stage, the remaining IN718 powder is added and mixed to obtain a powder mixture. Grinding was carried out in a single ball mill at a constant speed of 200 rpm and 25 balls with a diameter of 25 mm.

[0030] (3) Put the mixed powder into the SLM forming equipment, choose 304 stainless steel as the substrate, preheat the substrate to 120°C, and pass high-purity argon gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com