Medicament and process for treating and utilizing papermaking wastewater and waste residues

A technology of medicament and waste residue, which is applied in the direction of processing wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unfavorable large-scale continuous operation, increase resource input, occupy large land, etc., and achieve value and resources The effects of efficient utilization, compact treatment process, and safe production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

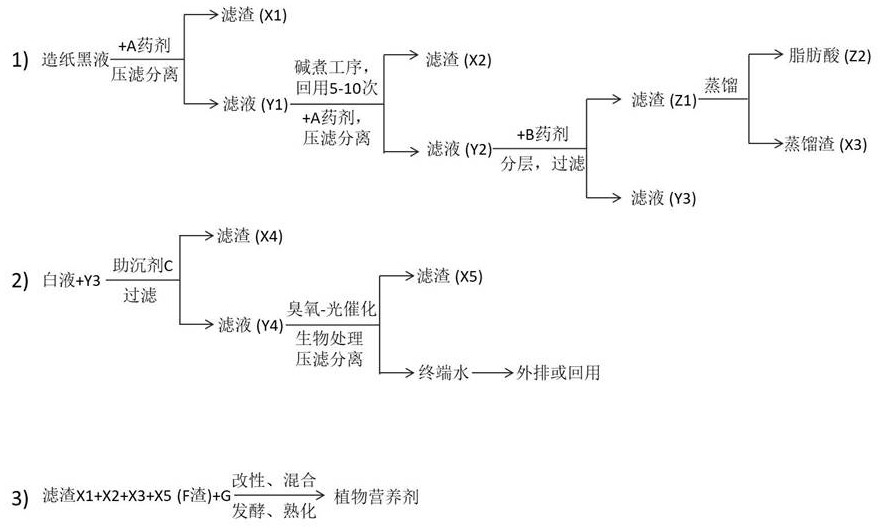

[0022] Embodiment 1: A certain cotton linter papermaking wastewater

[0023] First, add 5Kg of calcium oxide, 4Kg of polyferric sulfate, and 0.5Kg of carboxymethyl starch to 100Kg of a cotton linter papermaking black liquor, stir, filter, and record the filter residue as precipitate (X1), the filtrate as Y1, and the filtrate as Y1 After reusing the alkali boiling process for 5-10 times, add A agent calcium oxide 5Kg, polyferric sulfate 4Kg, carboxymethyl starch 0.5Kg, separate the precipitate (X2) and filtrate Y2, and add modifier B sulfuric acid to the filtrate Y2 4Kg to make it layered, collect the upper layer crude product (Z1), distill to obtain fatty acid products (Z2), the lower layer filtrate is Y3, and the distillation residue is X3, the lower layer filtrate Y3 and white liquor are combined and added heavy metal sedimentation aid C diamyl Potassium dithiophosphate 0.5Kg is separated to remove harmful heavy metals, filtered, the filter residue contains heavy metals (X4)...

Embodiment 2

[0024] Embodiment 2: A certain wood chip papermaking wastewater

[0025] First, add 5Kg of calcium oxide, 3Kg of polyferric sulfate, and 0.3Kg of carboxymethyl starch to 100 Kg of a wood chip papermaking black liquor, stir, filter, and record the filter residue as precipitation (X1), record the filtrate as Y1, and record the filtrate as Y1 times After boiling with alkali for 5-10 times, add A agent calcium oxide 5Kg, polyferric zinc sulfate 3Kg, starch 0.3Kg, separate precipitate (X2) and filtrate Y2, and add modifier B sulfuric acid 2Kg to filtrate Y2 to make it Layering, collecting the upper layer crude product (Z1), distilling to obtain fatty acid products (Z2), the lower layer filtrate is Y3, and the distillation residue is X3, the lower layer filtrate Y3 and white liquor are combined and added heavy metal sedimentation aid C butyl dithiophosphoric acid After sodium 0.3Kg, separate and remove harmful heavy metals, filter, the filter residue contains heavy metals (X4), filt...

Embodiment 3

[0026] Example 3: A straw papermaking wastewater

[0027] First, add 4Kg of A agent calcium oxide, 4.5Kg of polyferric sulfate, and 0.4Kg of carboxymethyl cellulose to 100 Kg of straw papermaking black liquor, stir, and filter. The filter residue is recorded as precipitation (X1), the filtrate is recorded as Y1, and the filtrate is Y1 After reusing the alkali boiling process for 5-10 times, add A agent calcium oxide 4Kg, polyferric sulfate 5Kg, carboxymethyl starch 0.6Kg, separate the precipitate (X2) and filtrate Y2, and add modifier B phosphoric acid to the filtrate Y2 3Kg to make it layered, collect the upper layer crude product (Z1), distill to obtain fatty acid products (Z2), the lower layer filtrate is Y3, and the distillation residue is X3, the lower layer filtrate Y3 and white liquor are combined and added heavy metal sedimentation aid C 8-hydroxyl - Quinoline 1Kg is separated to remove harmful heavy metals, filtered, the filter residue contains heavy metals (X4), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com