Diamond surface directional etching method

A technology of diamond and diamond particles, applied in the field of diamond surface directional etching, can solve the problems of pollution, time-consuming, complicated process, etc., and achieve the effects of simple operation method, increased surface roughness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

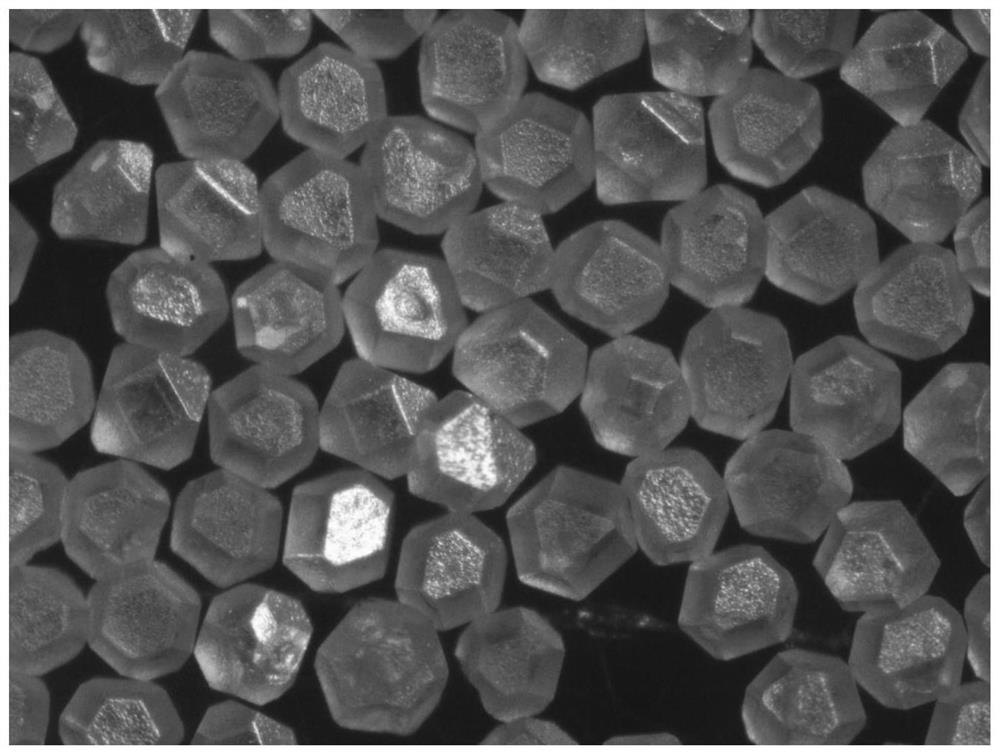

[0027] see Figure 1-3 , the present invention provides a technical solution: a diamond surface directional etching method, comprising the following steps:

[0028] Step 1). Prepare etching powder, take metal powder and MnO 2 One or more of the three compound powders of , SiC and TiC are mixed to obtain etching powder;

[0029] Step 2). The etching powder obtained in step 1) is mixed with diamond particles, and the ratio of the etching powder and diamond particles is (0.5~3):1;

[0030] Step 3). Add the raw materials obtained in step 2) into the three-dimensional mixer to obtain a uniformly mixed mixture;

[0031] Step 4). Add the mixture obtained in step 3) into an iron metal mold, level the mixture and then compact it into a prefabricated block with a thickness ≤ 1CM;

[0032] Step 5). Place the prefabricated block obtained in step 4) in a high-temperature furnace for reaction. The high-temperature furnace is heated to a set temperature of 600-850° C., kept for 0.5-10 hou...

Embodiment 2

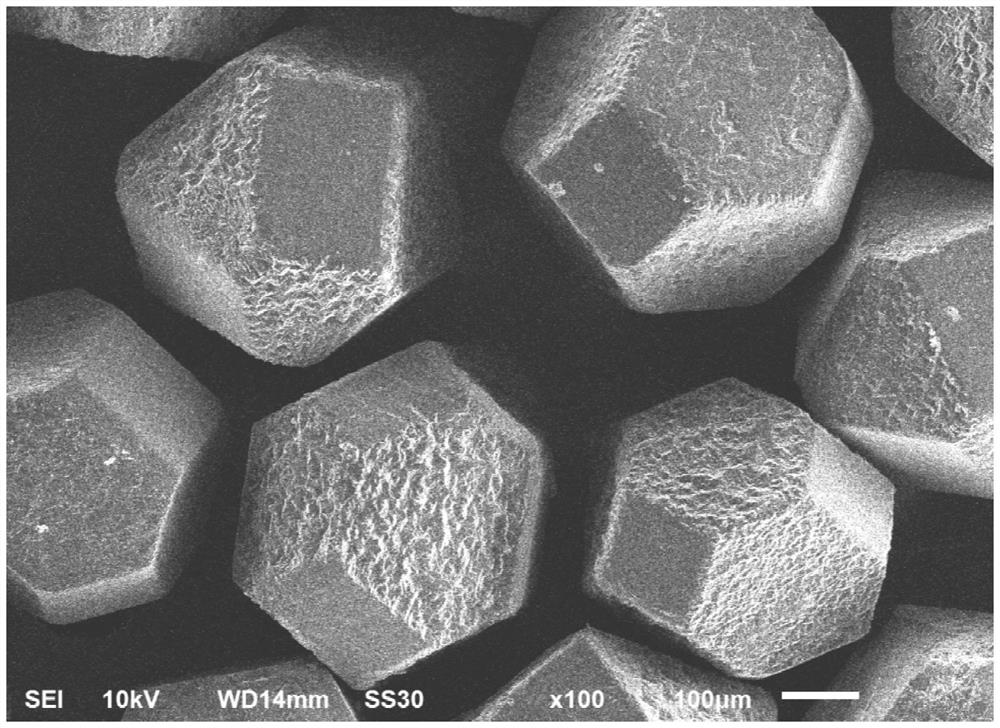

[0044] The surface of the diamond treated by this method is uniformly corroded, the average depth of the pits is 0.1 μm, the crystal grains maintain the original crystal form, and the diamond indicators are the same as those before treatment.

[0045] Specifically, the processing method is the same as in Example 1, except that:

[0046] Step 1) The weight percentage of each component of the etching powder is as follows: Ni: 15%, Co: 16%, Ti: 6%, Al: 1.5%, MnO 2 : 6%, SiC: 1.2%; TiC: 1%, the balance is Fe;

[0047] Step 2) mixing an appropriate proportion of etching powder and diamond particles. The ratio of etching powder to diamond is 2.5:1;

[0048] Step 5) The high-temperature furnace is set to heat up to a set temperature of 700°C for 2 hours: keep warm for 5 hours to stop heating, and then naturally cool to room temperature;

[0049] In the step 1), the meshes of the metal raw materials used in the etching powder are all less than 3000 mesh, and the oxygen content of t...

Embodiment 3

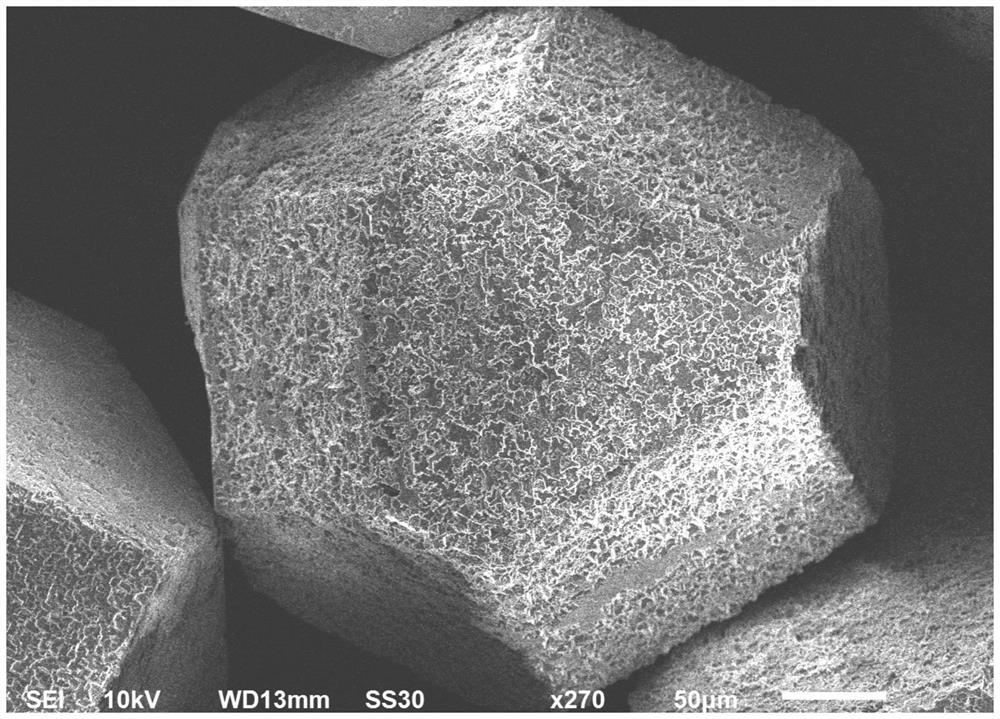

[0051]The diamond surface treated by this method is evenly corroded, and the {111} plane is more severely corroded than the {100} plane, and {111} forms corrosion pits with a triangular or hexagonal outline, with an average pit depth of 0.1 μm, while the {100} plane has only Slightly corroded, the indicators of the diamond are the same as those before treatment.

[0052] Specifically, the processing method is the same as that in Embodiment 2, except that:

[0053] Step 1) The weight percentage of each component of the etching powder is as follows: Ni: 8%, Co: 4%, Ti: 10%, Al: 0.4%, Fe: 12%, SiC: 3%; TiC: 0.5% , the balance being MnO 2 ;

[0054] Step 2) mixing an appropriate proportion of etching powder and diamond particles. The ratio of etching powder to diamond is 1.2:1;

[0055] Step 5) The high-temperature furnace is set to heat up to the set temperature of 800°C for 1.5 hours: keep warm for 4 hours to stop heating, and then naturally cool to room temperature;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com