Preparation method of catalyst for advanced treatment of industrial wastewater by ozone or hydrogen peroxide

A technology for advanced treatment and industrial wastewater, applied in catalyst activation/preparation, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalyst, etc., can solve secondary pollution, system instability, energy consumption Advanced problems, to achieve the effect of prolonging the service life, improving catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

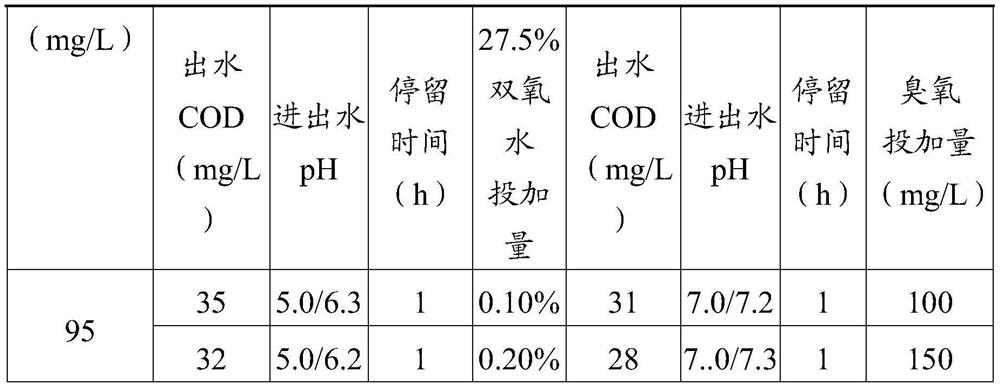

Examples

Embodiment 1

[0029] A preparation method of a catalyst for advanced treatment of industrial wastewater with ozone or hydrogen peroxide, the steps are as follows:

[0030] Step 1: After removing impurities from the sawdust, crush it to 100 mesh to obtain activated carbon raw material powder;

[0031] Step 2: drying the activated carbon raw material powder prepared in step 1 at 100°C to obtain a raw material powder with a water content of 18%;

[0032] Step 3: Put the raw material powder into the granulator to make a short columnar polymer, put it in an oven and bake it to shape, the temperature of the baking is 300°C, and the baking time is 3 hours;

[0033] Step 4: Phosphoric acid is configured into a solution with a mass fraction of 50%, which is used as an activator for standby;

[0034] Step 5: put the activator in step 4 and the polymer prepared in step 3 into the rotary kiln for carbonization activation according to the mass ratio of 1:3, control the roasting temperature in the rotar...

Embodiment 2

[0040] A preparation method of a catalyst for advanced treatment of industrial wastewater with ozone or hydrogen peroxide, the steps are as follows:

[0041] Step 1: After removing impurities from the sawdust, crush it to 100 mesh to obtain activated carbon raw material powder;

[0042] Step 2: drying the activated carbon raw material powder prepared in step 1 at 105°C to obtain a raw material powder with a water content of 18%;

[0043] Step 3: Put the raw material powder into the granulator to make a short columnar polymer, put it in an oven and bake it to shape, the temperature of the baking is 350°C, and the baking time is 2 hours;

[0044] Step 4: Phosphoric acid is configured into a solution with a mass fraction of 55%, which is used as an activator for standby;

[0045] Step 5: Put the activator in step 4 and the polymer prepared in step 3 into the rotary kiln for carbonization and activation according to the mass ratio of 1:3. Control the roasting temperature in the r...

Embodiment 3

[0051] A method for preparing a catalyst for advanced treatment of industrial wastewater with catalytic ozone or hydrogen peroxide, the steps are as follows:

[0052] Step 1: After removing impurities from the sawdust, crush it to 100 mesh to obtain activated carbon raw material powder;

[0053]Step 2: drying the activated carbon raw material powder prepared in step 1 at 110°C to obtain a raw material powder with a water content of 18%;

[0054] Step 3: Put the raw material powder into the granulator to make a short columnar polymer, put it in an oven and bake it to shape, the temperature of the baking is 400°C, and the baking time is 2.5 hours;

[0055] Step 4: Phosphoric acid is configured into a solution with a mass fraction of 60%, which is used as an activator for standby;

[0056] Step 5: put the activator in step 4 and the polymer prepared in step 3 into the rotary furnace for carbonization activation according to the mass ratio of 1:3, control the calcination temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com