Capacitive differential pressure sensor, manufacturing method and application thereof

A sensor and pressure difference technology, which is applied in the field of electronic component design, can solve the problems of high process conditions and difficult process, and achieve the effect of small fixed capacitance and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

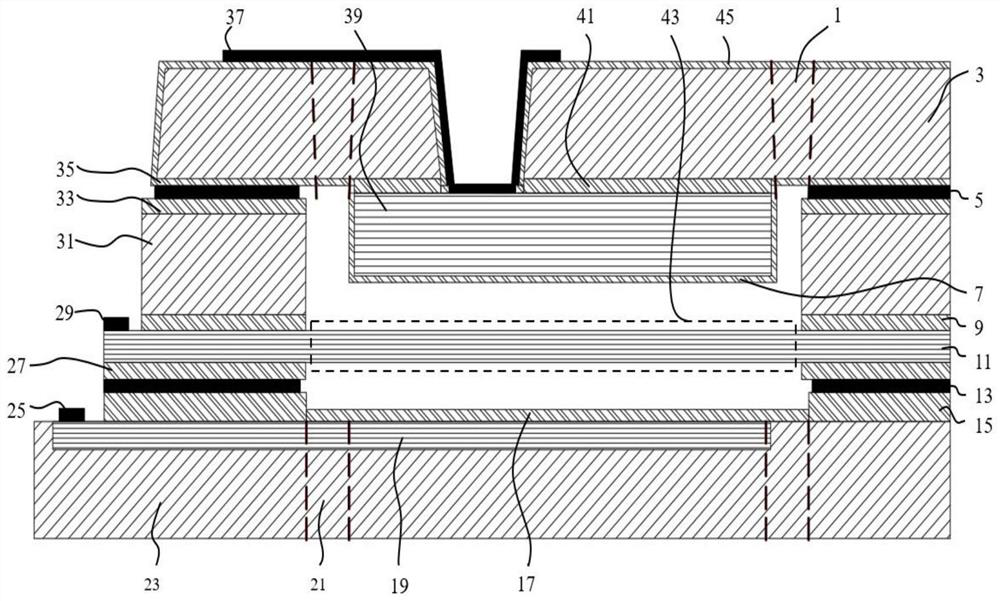

[0097] A device design scheme for a capacitive differential pressure sensor, including the following points:

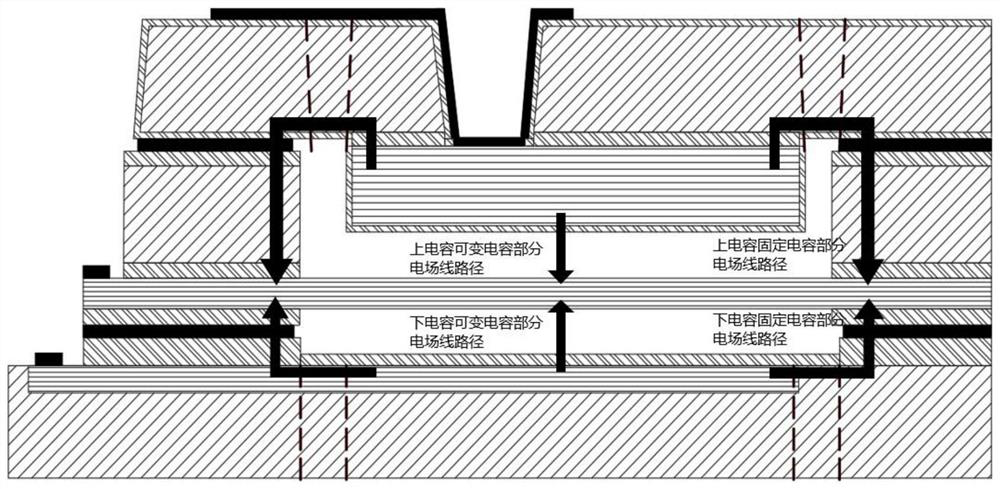

[0098] (1) The working principle of the sensor is differential capacitance, and there are three layers of electrodes on the upper, middle and lower layers, which are respectively located on the upper, middle and lower layers. The upper layer electrode 39 is located in the upper layer structure, the middle layer electrode 11 is located in the middle layer structure, and the lower layer electrode 19 is located in the lower layer structure. The middle electrode 11 forms upper and lower capacitors with the upper electrode 39 and the lower electrode 19 respectively. The pressure difference on both sides of the middle layer movable diaphragm 43 located in the middle layer electrode 11 causes the middle layer movable diaphragm 43 to deform and shift, causing the upper capacitance and lower capacitance to change, and then the signal can be output. The change of capacitance can...

Embodiment 2

[0139] MEMS (miniature electro-mechanical system) contact capacitive differential pressure sensor design method comprises the following steps:

[0140] (1) For the patterned fixed electrode and its lead circuit prepared by the doping process, high-dose, high-voltage deep doping is completed on the electrode part by ion implantation. Afterwards, the wet oxidation and planarization operations on the silicon wafer are completed, and the silicon oxide layer is partially etched to expose the patterned part of the electrode. The reason for the planarization operation is that the oxidation rate of the doped part is too high, causing the oxide layer surface of the doped part to be slightly higher than that of the undoped part, and the flatness of the entire wafer exceeds the bonding requirement. .

[0141] (2) Cutting grooves are respectively etched on the upper, middle and lower bonded silicon wafers. The width of the sensor area of the three silicon wafers is the same, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com