Clay-based composite material as well as preparation and use methods thereof

A composite material and clay technology, which is applied in the field of waterproof or water-repellent ultra-light clay-based composite materials, can solve the problems of cumbersome operation, inability to carry out secondary processing and transformation due to temperature increase, influence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

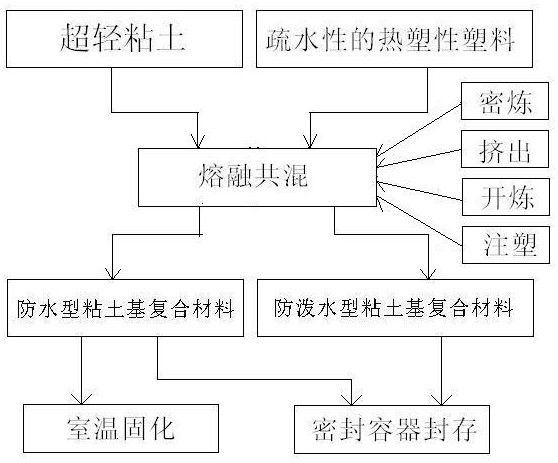

Method used

Image

Examples

Embodiment 1

[0042] Put ultra-light clay, PCL (melting point at about 65°C) and POE (melting point at about 66°C) into a high-speed mixer and mix evenly in a high-speed mixer at a temperature of 110°C Blending is carried out, the blending is melt blending, and the blending method is kneading to obtain a waterproof clay-based composite material, which is sealed in a sealed container.

[0043] Test results: Take 3g of the prepared composite material, shape it into a cube of 4cm×2cm×0.5cm, and after drying for 48 hours, heat the product at 300°C for half a minute at the first gear of the heat gun, cool and solidify at room temperature, immerse in water for 24 hours, no change, and dry Then heat the product again at 300°C for half a minute with a heat gun, shape one corner of it at a 90-degree right angle, cool and solidify at room temperature, the 90-degree right angle does not change the angle, and immerse in water for 24 hours, no change.

Embodiment 2

[0045] Put ultra-light clay, PCL (melting point is about 65°C) and EVA (melting point is about 60°C) according to the weight of 71 parts, 20 parts and 9 parts, put them into a high-speed mixer and mix them evenly, and the temperature is 100°C. Blending is carried out, the blending is melt blending, and the blending method is banburying to prepare a water-repellent clay-based composite material, which is sealed in a sealed container.

[0046] Test results: Take 2.5g of the prepared composite material, shape it into a cube of 4cm×2cm×0.5cm, dry it at room temperature for 48 hours, heat the product at 300°C for half a minute with a heat gun, cool and solidify at room temperature, immerse in water for 4 hours, a small amount of color Exudation, water swelling size 4.1cm×2.1cm×0.6cm, complete shape, size 4cm×2cm×0.5cm after drying, heat the product at 300°C for half a minute with a heat gun, and shape one corner of it at a 90-degree right angle , cooled and solidified at room tempe...

Embodiment 3

[0048] Put ultra-light clay, EVA (melting point around 60°C), TPU (melting point around 70°C) and maleic anhydride (MAH) into a high-speed mixer according to the parts by weight of 1, 70, 27 and 2 parts Mix evenly, and blend at a temperature of 120°C. The blending is melt blending, and the blending method is extrusion. The prepared composite material is obtained by extruding through a 0.5cm sheet die, and cooled at room temperature After curing, a waterproof clay-based composite material is obtained, which does not need to be sealed for storage.

[0049] Test results: take 2 prepared composite material sheets 4cm×2cm×0.5cm, total: 13g, heat the product at 300°C for half a minute at the first gear of the heat gun, shape a 3cm×3cm×1cm cube, cool and solidify at room temperature, pour 40 ℃ water immersion for 72 hours, no change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com