Polycarbonate and polymethyl methacrylate lamination adhesive resin, preparation method and application thereof

A technology of polymethyl methacrylate and polycarbonate, which is applied in the field of adhesive resin and preparation, can solve the problems that the film cannot be bonded according to the shape, the resin is difficult to obtain bonding, and the deformation of the laminated material is good. Effects of optical and mechanical properties, material shape stability, good adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

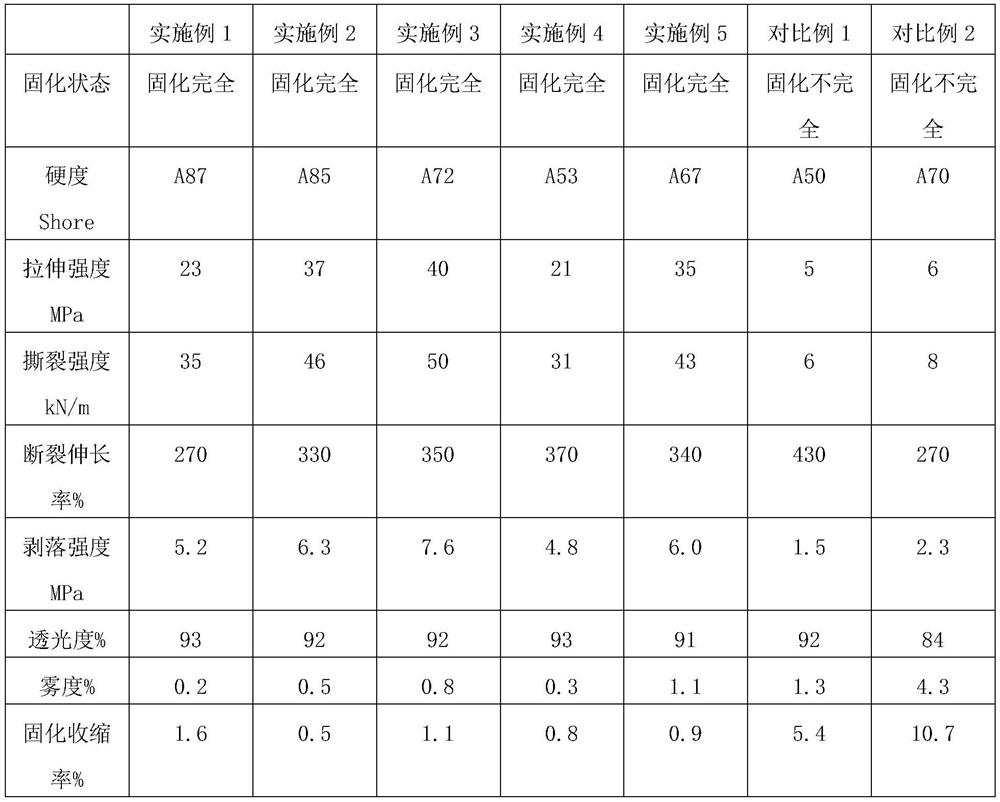

Examples

preparation example Construction

[0072] Another embodiment of the present invention proposes a kind of preparation method of polycarbonate and polymethyl methacrylate lamination bonding resin, it comprises:

[0073] Preparation of Component A: Place the polyisocyanate in a four-neck flask equipped with a thermometer, condenser, stirrer and constant pressure titration funnel, heat to 40-80°C, add 0.01-0.5wt% reaction catalyst; polyether Mix polyols, polycarbonate polyols and small molecule polyols to obtain second polyols, add the second polyols to polyisocyanate dropwise for 0.5-2 hours, and stir at 40-80°C for 3-6 hours , by testing that the NCO content is stable as the reaction end point, component A is obtained; wherein the molar ratio of the isocyanate group in the polyisocyanate to the second polyol is 1.4-4;

[0074] Preparation of component B: mixing hydroxyacrylic resin, the first polyol, transparent microspheres and additives to obtain component B;

[0075] Mix component A and component B according ...

Embodiment 1

[0088] One embodiment of the present invention proposes a kind of preparation method of polycarbonate and polymethyl methacrylate lamination bonding resin, it comprises:

[0089] Preparation of Component A: 100g of polyisocyanate IPDI was placed in a four-neck flask equipped with a thermometer, condenser, stirrer and constant pressure titration funnel, heated to 40°C, and 0.01g of reaction catalyst dibutyltin dilaurate was added; 120g of polyether polyol with a molecular weight of 1000 and 100g of polycarbonate polyol with a molecular weight of 1000 are mixed to obtain a second polyol, and the second polyol is added dropwise to a four-necked flask, and after 2 hours, the temperature is raised to Stir at 70°C for 4 hours, analyze the NCO group with an infrared spectrometer, stop the heating reaction when there is no change in the NCO peak, and obtain component A;

[0090] Preparation of component B: Mix 100g methyl methacrylate, 50g butyl methacrylate, and 50g hydroxypropyl met...

Embodiment 2

[0094] One embodiment of the present invention proposes a kind of preparation method of polycarbonate and polymethyl methacrylate lamination bonding resin, it comprises:

[0095] Preparation of Component A: 100g of polyisocyanate IPDI was placed in a four-neck flask equipped with a thermometer, condenser, stirrer and constant pressure titration funnel, heated to 40°C, and 0.01g of reaction catalyst dibutyltin dilaurate was added; 120g of polyether polyol with a molecular weight of 1000 and 100g of polycarbonate polyol with a molecular weight of 1000 are mixed to obtain a second polyol, and the second polyol is added dropwise to a four-necked flask, and after 2 hours, the temperature is raised to Stir at 70°C for 4 hours, analyze the NCO group with an infrared spectrometer, stop the heating reaction when there is no change in the NCO peak, and obtain component A;

[0096] Preparation of component B: Mix 100g methyl methacrylate, 50g butyl methacrylate, and 50g hydroxypropyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com