SCR catalyst and preparation method thereof

A kind of SCR catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problems of zeolite structure collapse, catalytic activity deterioration, etc., and achieve the effect of high thermal durability and excellent NOx purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

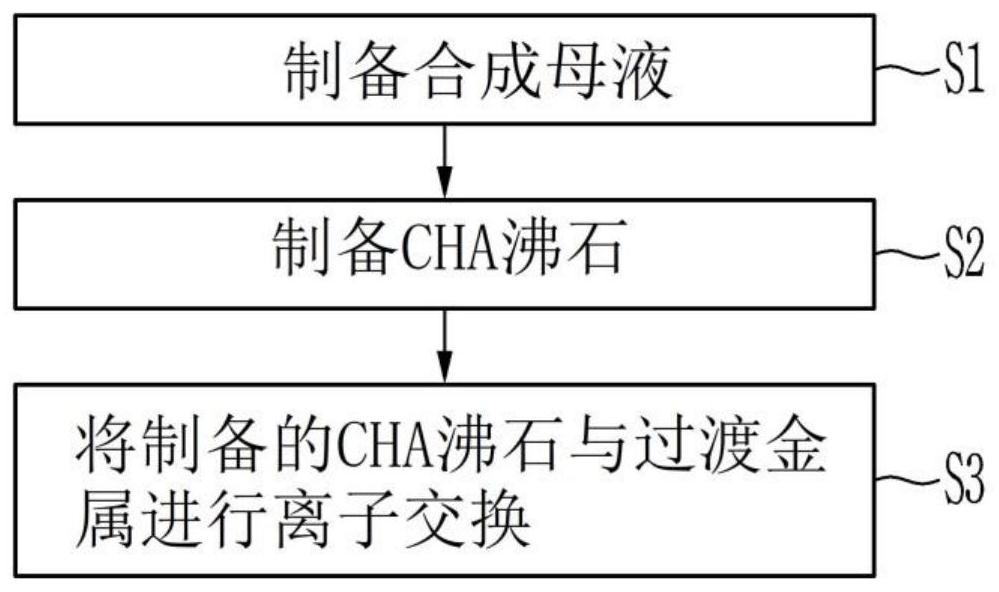

[0035] A method for preparing an SCR (Selective Catalytic Reduction) catalyst according to an embodiment of the present disclosure includes: preparing a synthesis mother liquor including a supply source of silica and alumina including zeolite A and silica, a structure inducing material, a complex compounding materials and solvents; reacting the synthesis mother liquor to prepare CHA zeolite; and ion-exchanging the prepared CHA zeolite with a transition metal.

[0036] figure 1 is a process flow diagram illustrating a method for preparing an SCR catalyst according to an embodiment of the present disclosure. In the following, refer to figure 1 , the preparation method of the SCR catalyst is described.

[0037] Firstly, in step S1, a synthesis mother liquor comprising a supply source of silica and alumina, a structure-inducing material, a complexing material, and a solvent is prepared.

[0038] When zeolite A is used as a supply source of silica and alumina, a CHA zeolite havi...

Embodiment 1

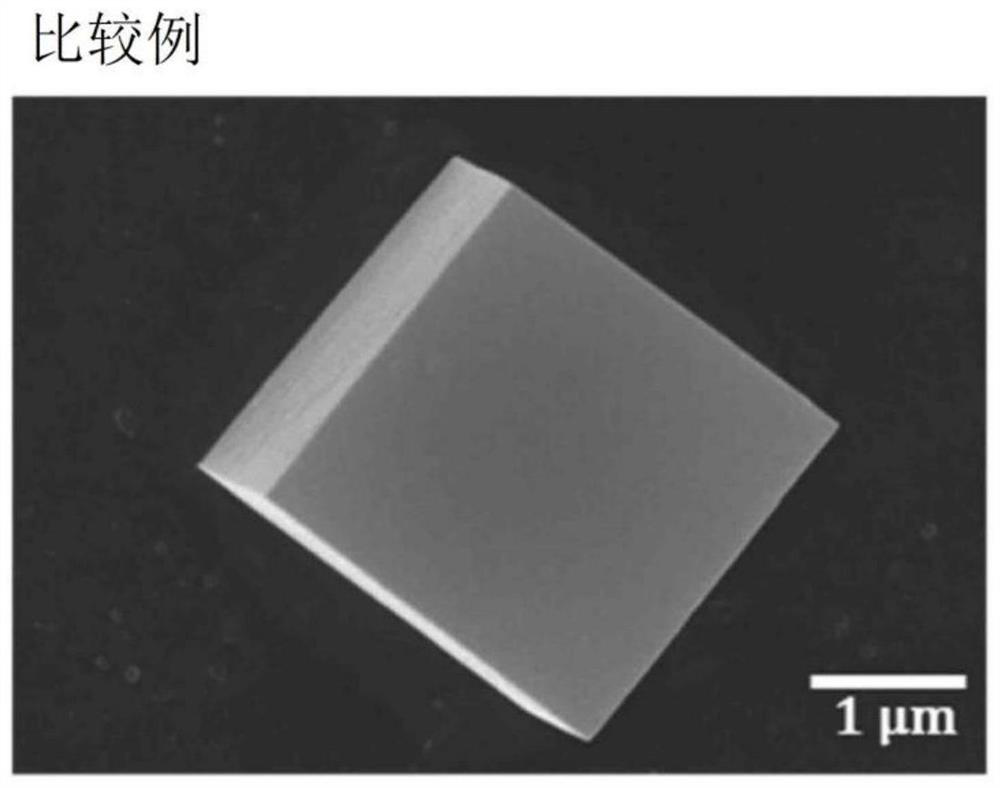

[0064] CHA zeolite (CHA-2A) and copper ion-exchanged CHA zeolite (Cu / CHA-2A) were prepared in the same manner as in Comparative Example, except that a synthesis mother liquor was prepared using the composition shown in Table 1 below.

Embodiment 2

[0066] CHA zeolite (CHA-2B) and copper ion-exchanged CHA zeolite (Cu / CHA-2B) were prepared in the same manner as in Comparative Example, except that a synthetic mother liquor was prepared using the composition shown in Table 1 below.

[0067] Table 1

[0068]

[0069] 1) SDA: Trimethyladamantyl ammonium hydroxide (AdaOH)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com