Zeolite having improved heat resistance and catalyst composite using same

A technology of catalysts and oxidation catalysts, applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

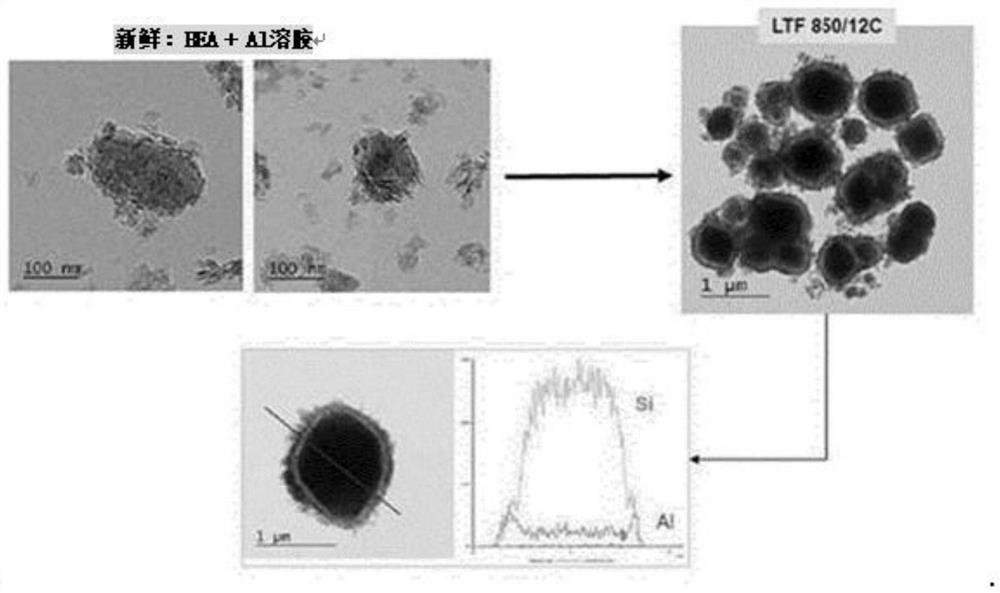

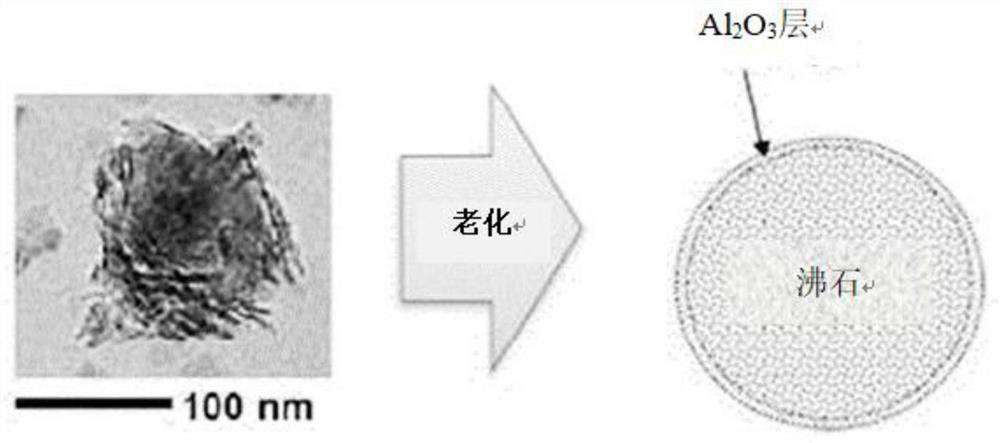

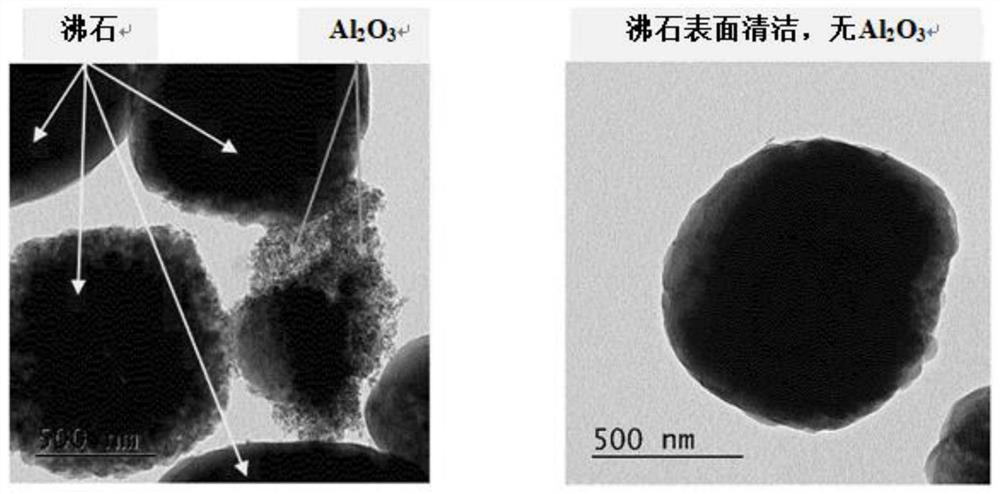

[0021] The invention relates to a reformed zeolite coated with alumina sol, a catalyst product with the reformed zeolite placed on a carrier, and an exhaust gas treatment system comprising the catalyst product.

[0022] Zeolite is a crystalline aluminum silicate material that typically has uniform pore sizes of about 3 to 10 Angstroms in diameter, depending on the type of zeolite and the type and number of cations contained in the zeolite lattice. It is a pore size crystalline aluminosilicate aqueous coatings. Those skilled in the art are familiar with the use of zeolites, synthetic zeolites as well as natural zeolites, to facilitate specific reactions, including the selective reduction of nitrogen oxides with ammonia gas as the reducing agent. The object of the present invention is to improve the heat resistance of zeolites by reforming the zeolites, especially by using alumina sols for the preparation of the reformed zeolites. As used herein, the term "alumina sol" is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com