Wide-temperature-range huge negative thermal expansion metal-based composite material and preparation method thereof

A technology of negative thermal expansion and composite materials, which is applied in the field of composite materials, can solve the problems of few types of negative thermal expansion materials, narrow temperature, and unsatisfaction with actual needs, and achieve the effects of low cost, improved mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

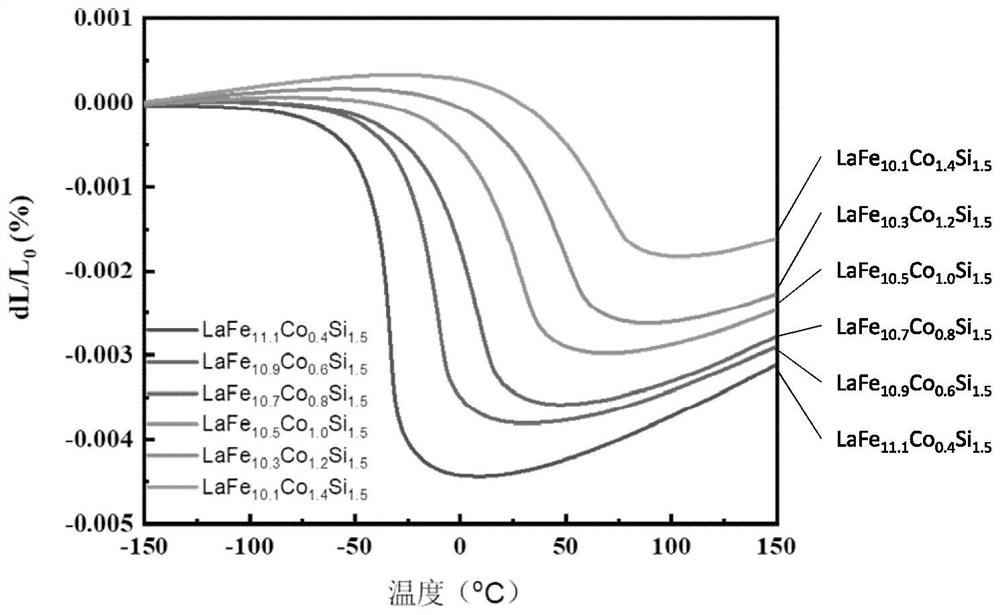

[0041] This embodiment provides a huge negative thermal expansion metal matrix composite material in a wide temperature range and a preparation method thereof. The huge negative thermal expansion metal matrix composite material is La(Fe 1-y-z ,Co y , Si z ) 13 system materials, including the following steps:

[0042] Step S101, according to the stoichiometric ratio of 1:11.5-n:n:1.5 (n=0.4, 0.6, 0.8, 1.0, 1.2, 1.4), respectively weigh the metal elements La, Fe, Co, Si (purity ≥ 99.5%), Placed in an electric arc furnace, smelted at high temperature under an argon atmosphere, smelted 4 times, turned the ingot once after each smelting to homogenize the alloy ingot, and annealed the prepared alloy ingot at 700°C in a vacuum environment for 5 days, six kinds of alloys were obtained; the purpose of long-time high-temperature annealing of alloy ingots is to make the alloy ingots completely generate NaZn 13 Type cubic phase crystal structure La(Fe, Co, Si) 13 , due to NaZn 13 La...

Embodiment 2

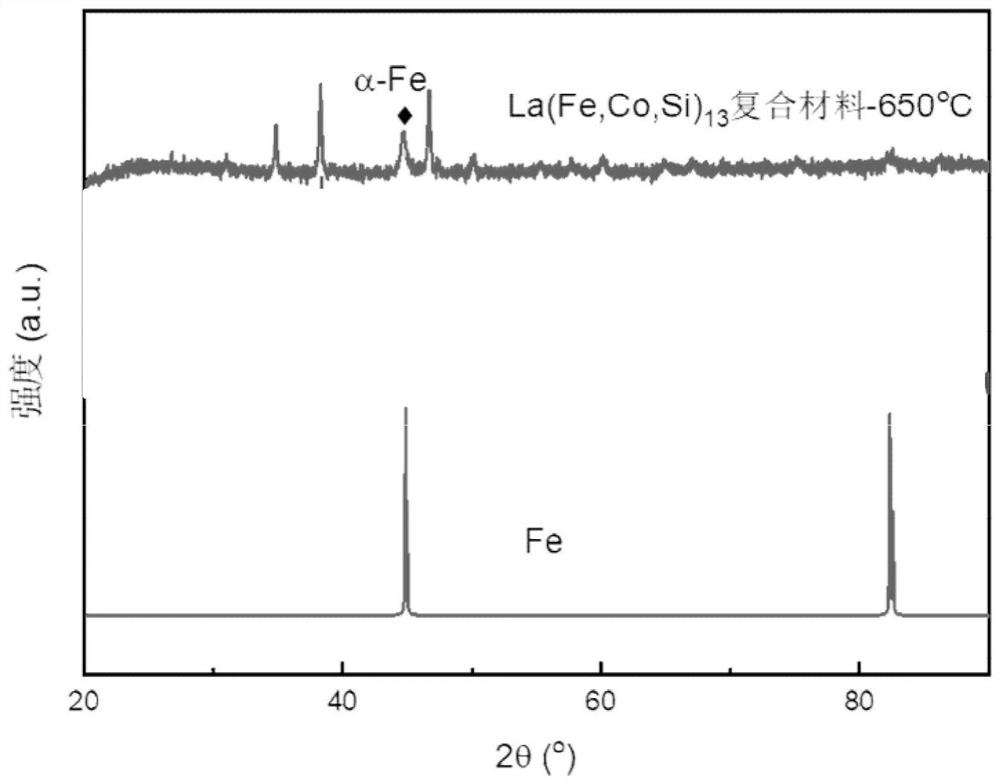

[0053] This embodiment provides a huge negative thermal expansion metal matrix composite material in a wide temperature range and a preparation method thereof. The huge negative thermal expansion metal matrix composite material is La(Fe 1-y-z ,Co y , Si z ) 13 system materials, including the following steps:

[0054] Step S201, according to the stoichiometric ratio of 1:11.5-n:n:1.5 (n=0.4, 0.6, 0.8, 1.0, 1.2, 1.4), respectively weigh the metal elements La, Fe, Co, Si (purity ≥ 99.5%), Placed in an electric arc furnace, smelted at a high temperature under an argon atmosphere, smelted 8 times, turned the ingot once after each smelting to homogenize the alloy ingot, and annealed the prepared alloy ingot at 1300°C in a vacuum environment for 15 Days, get six alloys.

[0055] Step S202, adding alcohol to the annealed alloy ingot and grinding it into powder. The particle size of the alloy powder is in the range of 0.5-100 μm. The grinding method includes manual grinding and bal...

Embodiment 3

[0060] This embodiment provides a huge negative thermal expansion metal matrix composite material in a wide temperature range and a preparation method thereof. The huge negative thermal expansion metal matrix composite material is La(Fe 1-y-z ,Co y , Si z ) 13 system materials, including the following steps:

[0061] Step S301, according to the stoichiometric ratio of 1:11.5-n:n:1.5 (n=0.4, 0.6, 0.8), respectively weigh the metal elements La, Fe, Co, Si (purity ≥ 99.5%), and place them in an electric arc furnace, High-temperature smelting under argon atmosphere, smelting 4 times, turning the ingot once after each smelting to homogenize the alloy ingot, and annealing the prepared alloy ingot at 1000°C for 10 days in a vacuum environment to obtain three alloys .

[0062] Step S302, adding alcohol to the annealed alloy ingot and grinding it into powder. The particle size of the alloy powder is in the range of 0.5-100 μm. The grinding method includes manual grinding and ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com