Multi-cavity chemical vapor deposition equipment

A chemical vapor deposition, multi-cavity technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of hot wire service life, high cost, poor quality, etc., to save Hardware investment cost and operating cost, avoid cross-contamination, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

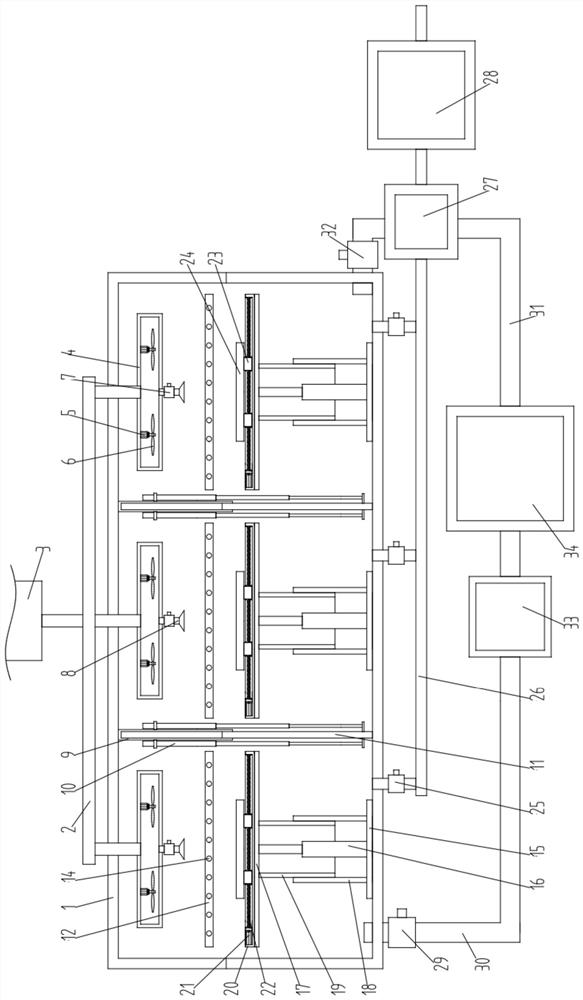

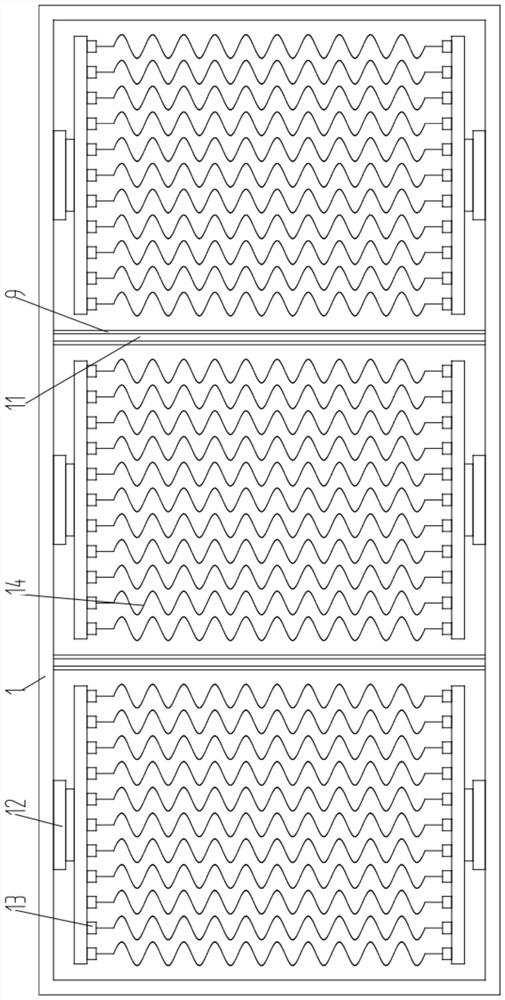

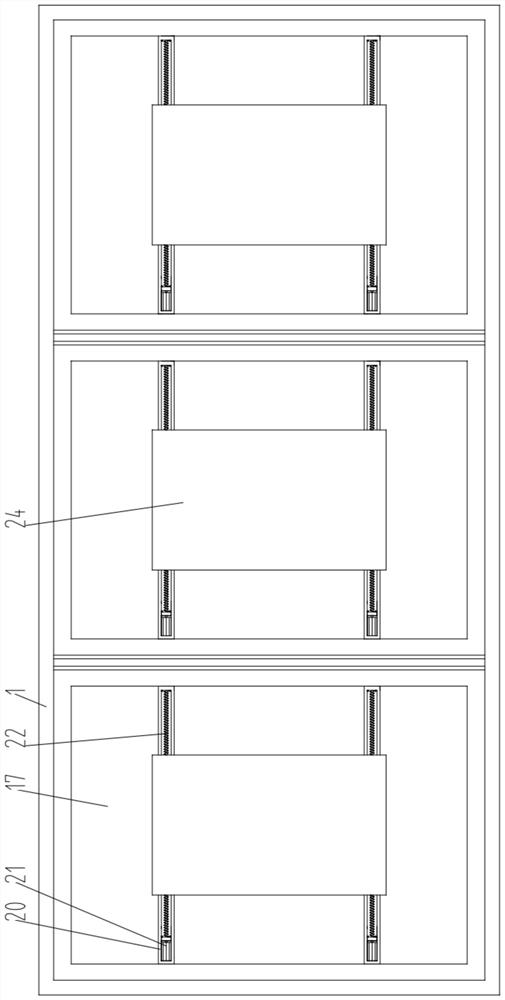

[0036] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 Shown, a multi-chamber chemical vapor deposition equipment.

[0037] All the electrical components in this case are connected with their corresponding power supply through wires by personnel in the field, and the appropriate controller should be selected according to the actual situation to meet the control requirements. The specific connection and control sequence should refer to the following working principle Among them, the electrical connections between the electrical components are completed sequentially, and the detailed connection methods are well known in the art. The following mainly introduces the working principle and process, and does not explain the electrical control.

[0038] A multi-box 1 chemical vapor deposition equipment, including a box 1, a gas supply structure is arranged on the box 1, the inside of the box 1 is divided into multiple cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com