Hydroxyapatite as well as preparation method and application thereof in dark fermentation hydrogen production

A hydroxyapatite and dark fermentation technology, which is applied in the field of hydroxyapatite and its preparation, can solve the problems of single promotion effect and poor hydrogen production effect, and achieves the advantages of improving activity, improving hydrogen production performance, and optimizing microbial community structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of hydroxyapatite comprises the following steps:

[0047] (1) At room temperature (25° C.) and under magnetic stirring, drop the diammonium hydrogen phosphate solution into the calcium nitrate tetrahydrate solution (Ca:P molar ratio=1.67) by titration, and the titration time is 20 min; Ca(NO 3 ) 2 4H 2 O solution concentration is 1g / L; (NH 4 ) 2 HPO 4 The solution concentration is 0.6g / L.

[0048] (2) The resulting mixed solution was kept at room temperature (25° C.) under magnetic stirring, and ammonia solution was added to keep the pH of the solution at 12.

[0049] (3) Continue stirring and reacting at 90° C. for 3 hours. After the reaction is complete, pour it into a beaker to cool, suction filter, and dry.

[0050] (4) Grinding the dried sample obtained in the above steps; sintering at 900° C. for 3 hours, and continuing drying for 24 hours to finally obtain hydroxyapatite.

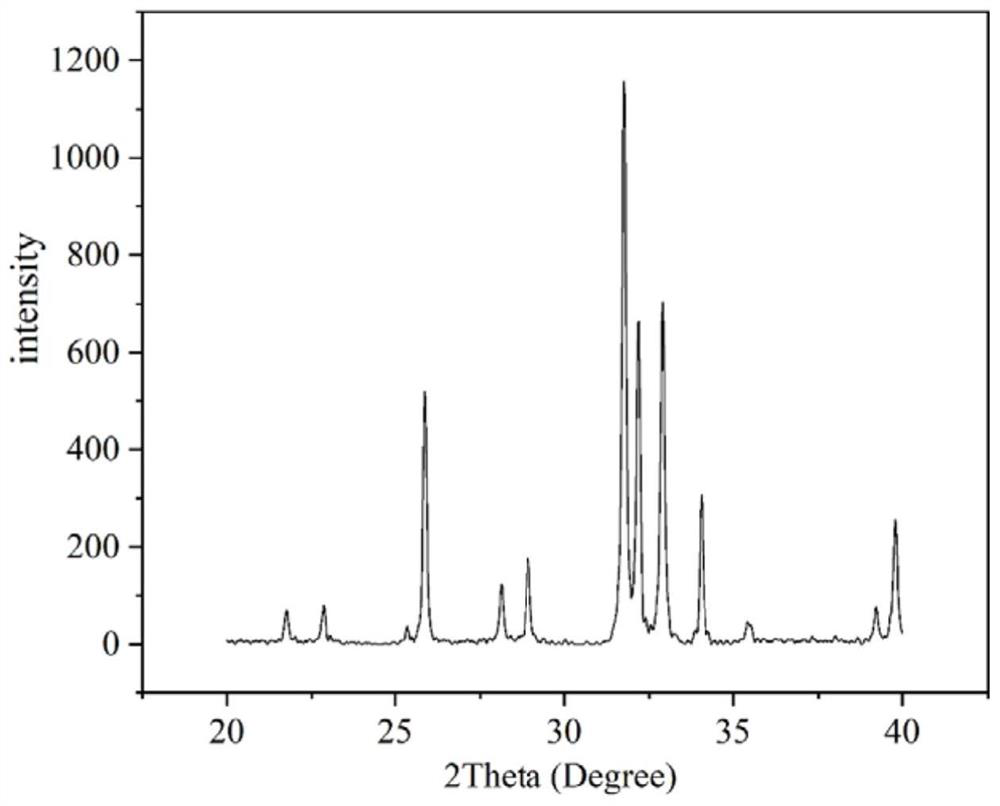

[0051] Depend on figure 1 The X-ray diffraction pattern of hydrox...

Embodiment 2

[0067] (1) The preparation of hydroxyapatite comprises the following steps:

[0068] (1) At room temperature (25° C.) and under magnetic stirring, drop the diammonium hydrogen phosphate solution into the calcium nitrate tetrahydrate solution (Ca:P molar ratio=1.67) by titration, and the titration time is 20 min; Ca(NO3) 2 4H 2 O solution concentration is 2g / L; (NH 4 ) 2 HPO 4 The concentration is 1.2g / L.

[0069] (2) The obtained mixed solution is at room temperature (25° C.) under magnetic stirring, and ammonia solution is added to keep the pH of the solution at 12;

[0070] (3) Continue stirring and reacting at 90° C. for 3 hours. After the reaction is complete, pour it into a beaker to cool, suction filter, and dry.

[0071] (4) Grinding the dried sample obtained in the above steps; sintering at 900° C. for 3 hours, and continuing to dry for 24 hours to finally obtain hydroxyapatite (HA).

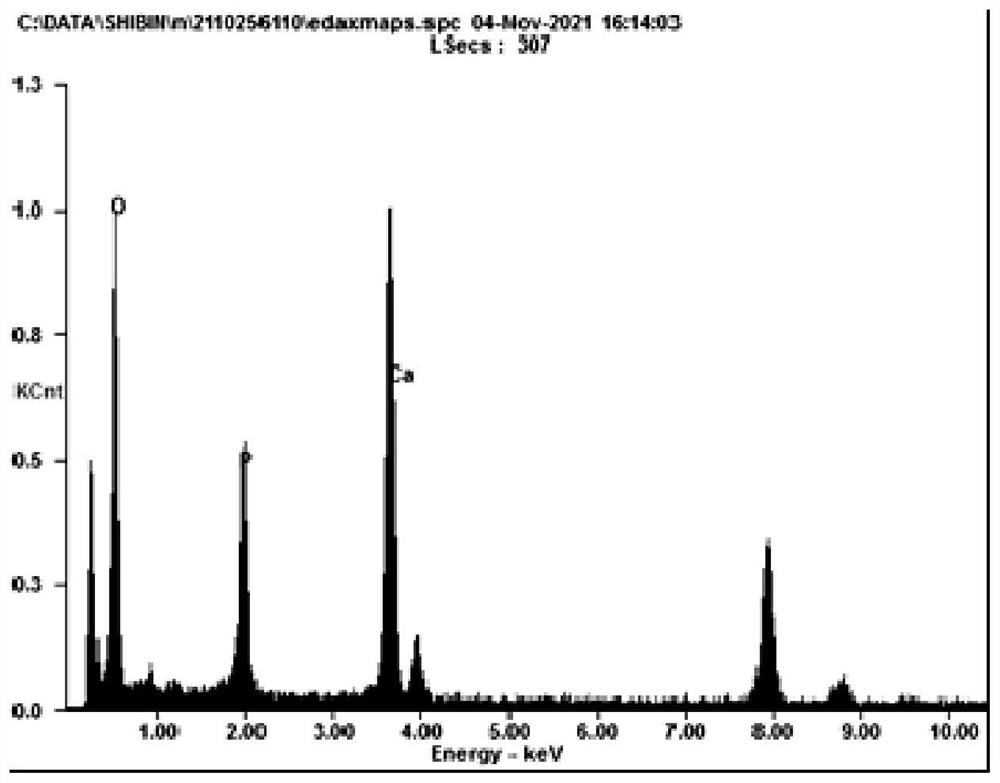

[0072] The HA obtained in Example 2 was subjected to elemental analysis by ED...

Embodiment 3

[0076] (1) Preparation of hydroxyapatite:

[0077] (1) At room temperature (25°C) and under magnetic stirring, drop diammonium hydrogen phosphate solution into calcium nitrate tetrahydrate solution by titration, and the titration time is 20min; Ca(NO 3 ) 2 4H 2 O solution concentration is 0.5g / L; (NH 4 ) 2 HPO 4 The concentration is 0.3g / L.

[0078] (2) The resulting mixed solution was kept at room temperature (25° C.) under magnetic stirring, and ammonia solution was added to keep the pH of the solution at 12.

[0079] (3) Continue stirring and reacting at 90° C. for 3 hours. After the reaction is complete, pour it into a beaker to cool, suction filter, and dry.

[0080] (4) Grinding the dried sample obtained in the above steps; sintering at 900° C. for 3 hours, and continuing to dry for 24 hours to finally obtain hydroxyapatite (HA).

[0081] Elemental analysis of HA (Example 3) was performed by EDS. The results showed that the atomic percentages of O, Ca and P were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

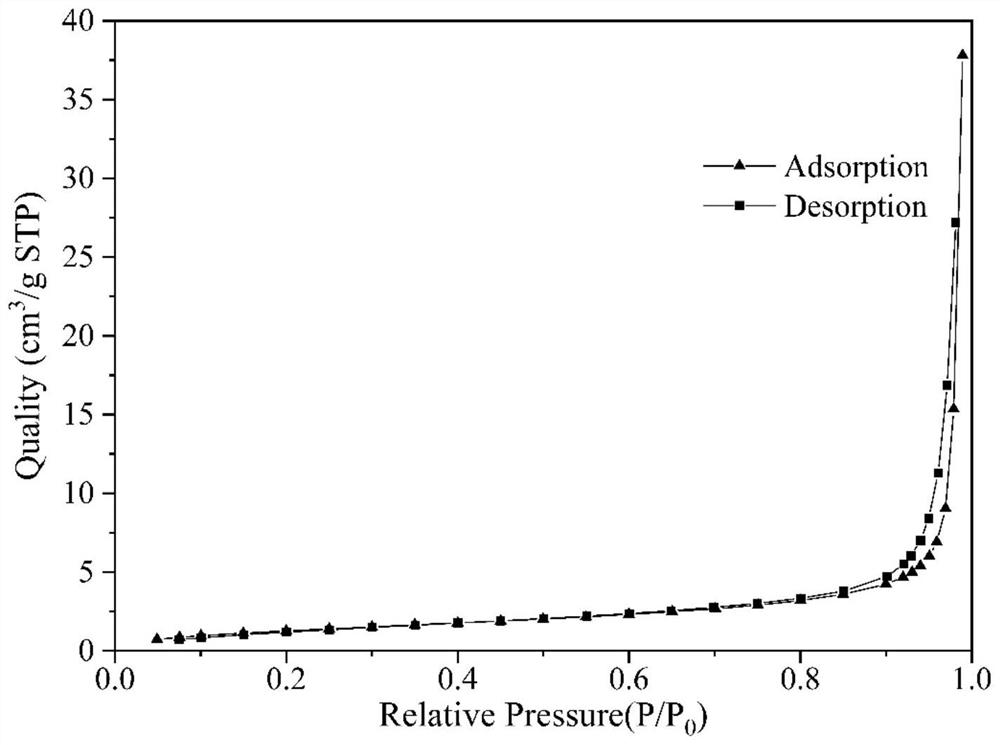

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com