Efficient metallographic examination sample grinding method

A metallographic inspection and grinding method technology, which is applied in the field of efficient metallographic inspection sample grinding, can solve the problems of lower sample preparation efficiency, increased labor intensity, and high grinding requirements, so as to improve sample processing efficiency and reduce grinding Steps to ensure the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] An efficient metallographic inspection sample grinding method, grinding 10*20mm metallographic standard size sample includes the following steps:

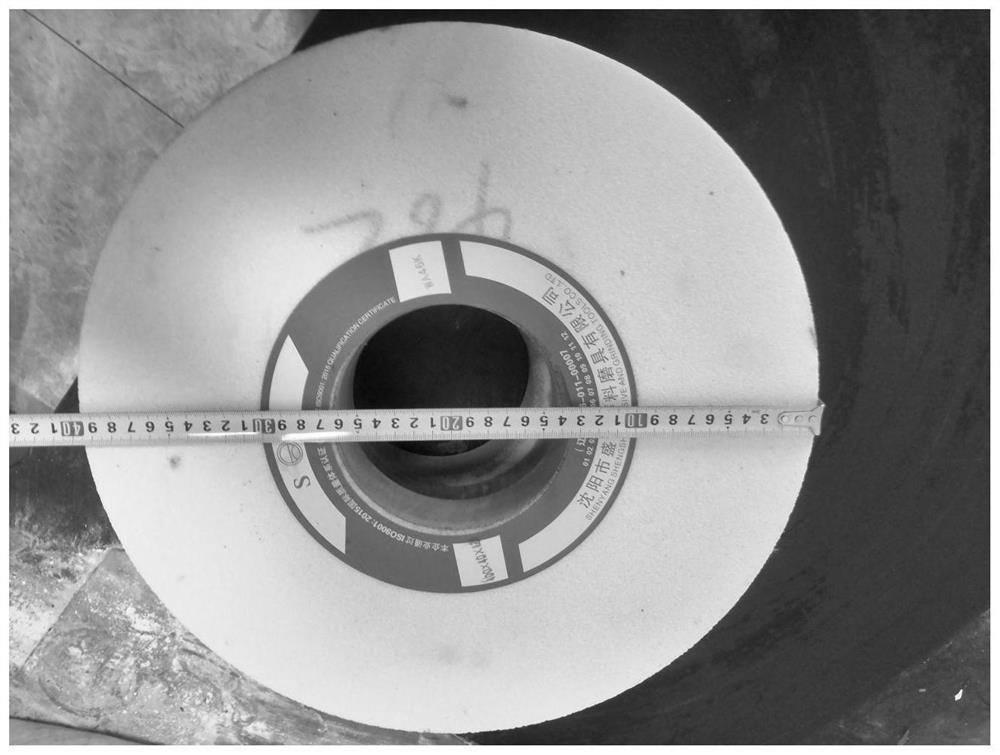

[0031] Step 1. Coarse grinding: use a metallographic sample grinding machine to grind with a 50# grinding wheel, the diameter of the grinding wheel is 400mm, and the grinding time used when the grinding depth is 0.5mm is 50s.

[0032] In an efficient metallographic examination sample grinding method described in this embodiment, the line-out speed of the grinding wheel in step 1 is 1821.2 m / min.

[0033] A kind of high-efficiency metallographic examination sample grinding method described in this embodiment, step 1 is through improving the metallographic sample grinding machine, changing the equipment parameters used for grinding and replacing the 50# grinding wheel for grinding, and changing the parameters of the original equipment The size of the grinding tray is sufficient to be able to install a grinding wheel with a dia...

specific Embodiment approach 2

[0039] A kind of high-efficiency metallographic examination sample grinding method according to specific embodiment 1 also includes the following steps:

[0040] Step 2, fine grinding: Use a polishing machine to grind with 240# sandpaper, the diameter of the sandpaper is 300mm, the speed is 1450r / min, and the grinding time is 22s.

[0041] In an efficient metallographic inspection sample grinding method described in this embodiment, the line speed of the sandpaper in step 2 is 1365.9 m / min.

[0042] In an efficient metallographic examination sample grinding method described in this embodiment, the grinding depth in step 2 is 0.3 mm.

[0043] A kind of high-efficiency metallographic examination sample grinding method described in the present embodiment, the two steps of step 2 combining conventional semi-fine grinding 600# and fine grinding 1500# are one step, and the improved grinding and polishing equipment used is installed 240 #Sandpaper, the maximum speed: 1450r / min, the ...

specific Embodiment approach 3

[0048] A kind of high-efficiency metallographic examination sample grinding method according to specific embodiment 1 also includes the following steps:

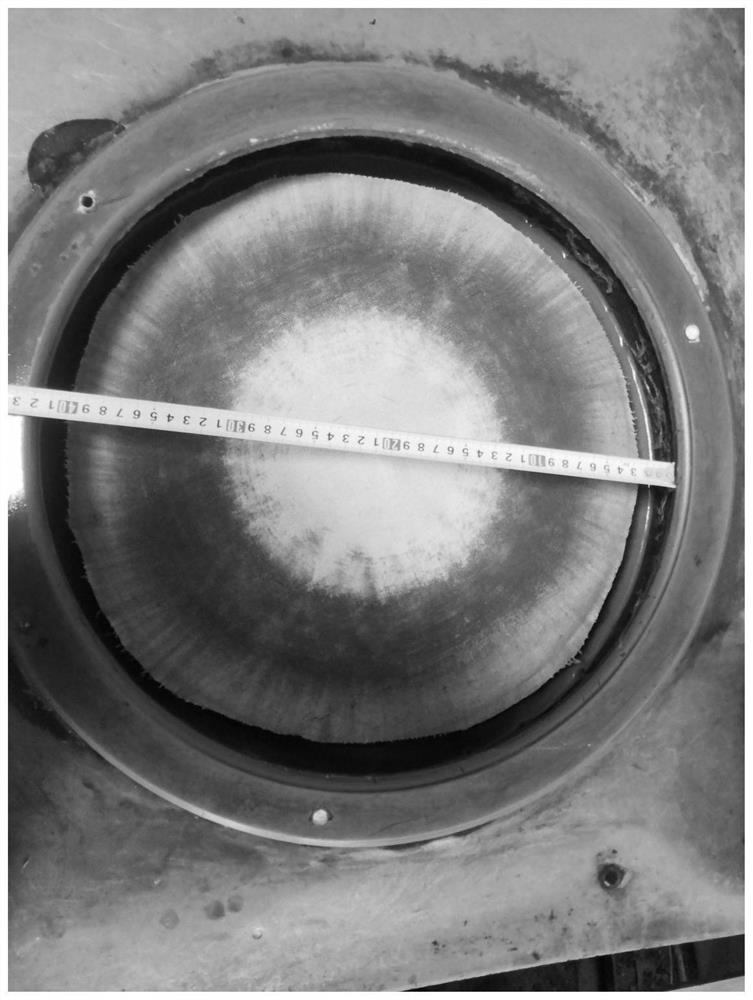

[0049] Step 3. Coarse polishing: use a grinding and polishing machine to perform rough polishing with coarse canvas combined with emery suspension. The diameter of the coarse canvas is 400mm, the rotational speed is 1450r / min, and the grinding time is 30s.

[0050] In the highly efficient method for grinding samples for metallographic examination described in this embodiment, the concentration of the corundum suspension in step 3 is 5-10 wt%, and the corundum used is 380# corundum.

[0051] In an efficient metallographic inspection sample grinding method described in this embodiment, the line-out speed of the coarse canvas in step 3 is 1821.2 m / min, and the grinding depth is 0.1 mm.

[0052] An efficient metallographic examination sample grinding method described in this embodiment, the maximum speed of the improved grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com