High-blocking-ratio fin layer plate cooling structure and method for turbine blade mid-chord area

A technology for turbine blades and cooling structures, which is applied to blade support components, machines/engines, mechanical equipment, etc., can solve the problems of large compressor power loss and pressure loss, and achieve increased air intake, reduced pressure loss, and suppression of cross flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

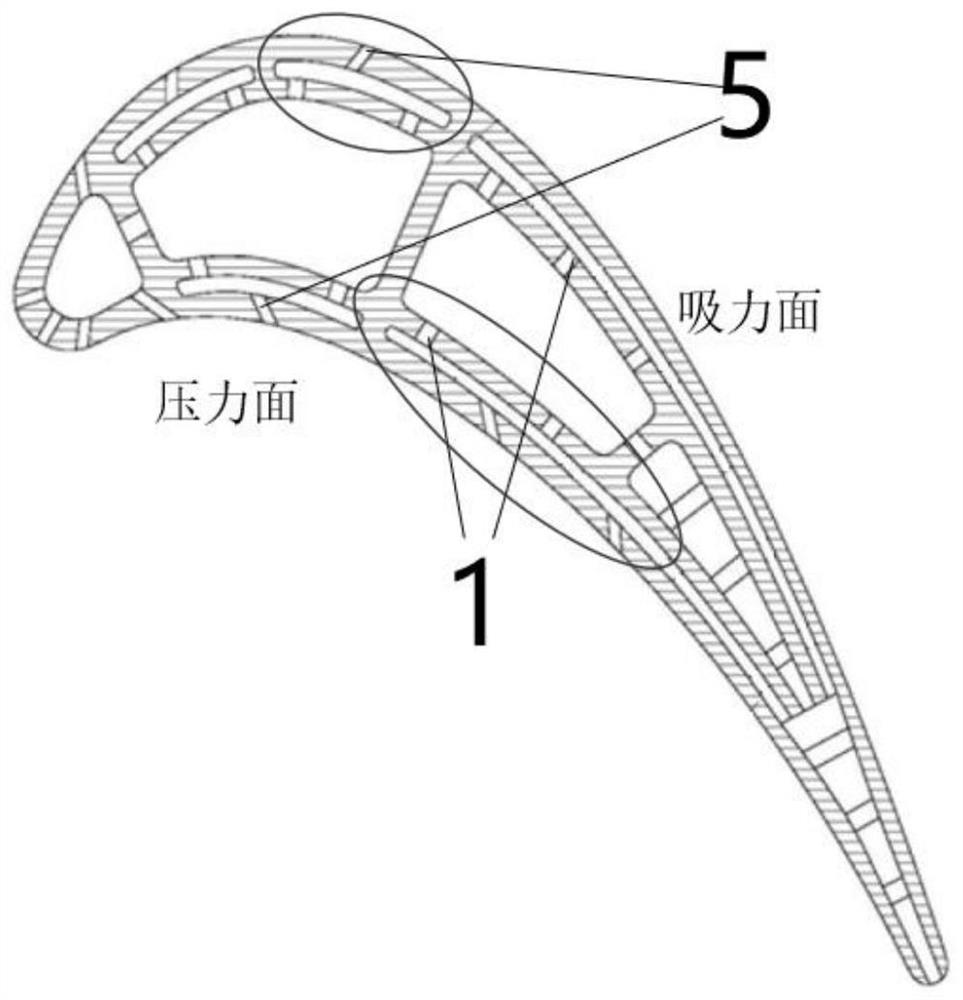

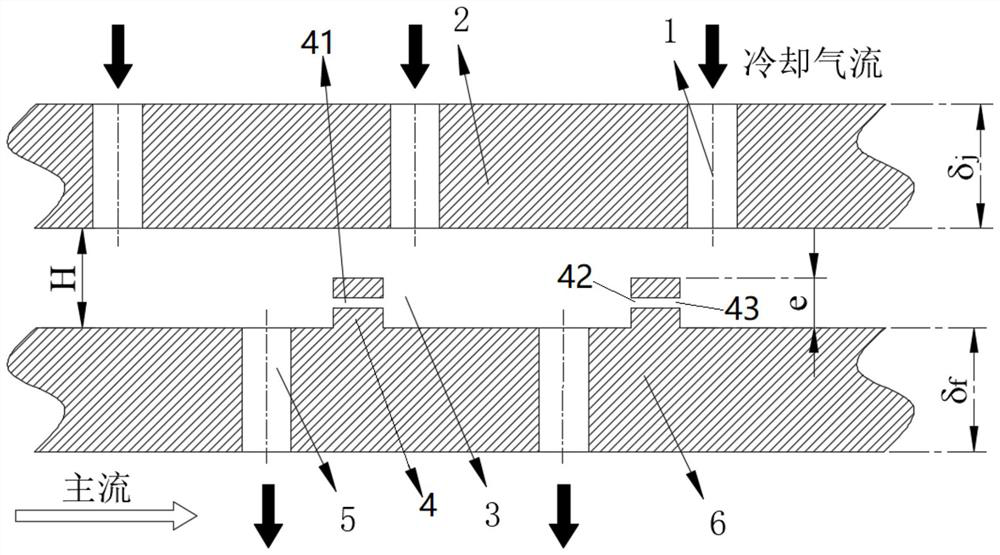

[0039] Embodiment 1: as Figure 1-4 , Figure 10 Shown, a kind of turbine blade middle chord region uses the cooling structure of the high clogging ratio rib laminate, comprises the blade double wall that is positioned at blade mid chord, and described blade double wall is made of air film orifice plate 6 and impingement orifice plate 2, and the impingement air flow cooling passage 3 between the air film orifice plate 6 and the impact orifice plate 2; the impact orifice plate 2 is an air inlet plate, which is arranged on the cold air side of the turbine blade; the air film orifice plate 6 is an air outlet plate The air film orifice plate 6 is arranged on the gas side of the turbine blade; the impact orifice plate 2 and the air film orifice plate 6 both have a thickness of 0.5-3d and a spanwise width of 4-8d.

[0040]On described air film orifice plate 6, be provided with air film hole 5 evenly and equidistantly, be provided with impact hole 1 evenly and equidistantly on descr...

Embodiment 2

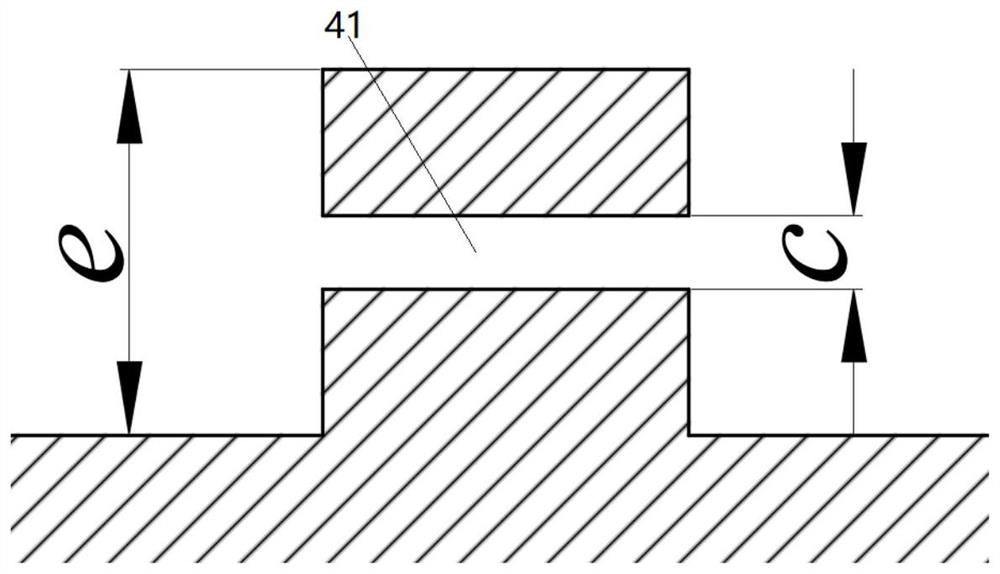

[0045] Embodiment 2: as Figure 6-8 As shown, the parallel slits 41 are arranged obliquely relative to the flow direction of the airflow, the inclination angle α is 0-30°, and the penetration rate β=c / e is 0.05-0.4, wherein c is the ratio of the parallel slits 41 Height, e is the height of the fin 4 with high blockage ratio.

Embodiment 3

[0046] Embodiment 3: as Figure 5 As shown, the present invention also provides the cooling method of the high clogging ratio fin laminate cooling structure for the midchord region of the turbine blade described in Embodiment 1, comprising the following steps:

[0047] The cooling air flow passes through the impact hole 1 to perform impact heat exchange on the inner wall surface of the air film orifice plate 6, and the cooling air flow impacting the air film orifice plate 6 diffuses to form a wall jet A, and then forms a cross flow B along the direction of the cold air flow; at this time, The high blockage ratio fins 4 play a role in strengthening the turbulence of the cooling air flow, and the upwardly deflected wall jet A1 generated in the upstream area of the impingement hole 1 is separated from the downward flow jet A1 separated from the upper surface of the adjacent high blockage ratio fins 4 . The cooling air flow A2 is mixed, and a small recirculation zone A3 is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com