Nano liquid disperse dye with high washing fastness as well as preparation method and application of nano liquid disperse dye

A technology for disperse dyes and wash fastness, which is applied in dyeing, organic dyes, textiles and papermaking, etc. It can solve the problems of poor wash fastness and difficult sanding of dyes with high water washability, and achieves prevention of aggregation and sedimentation and excellent dispersion effect , high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

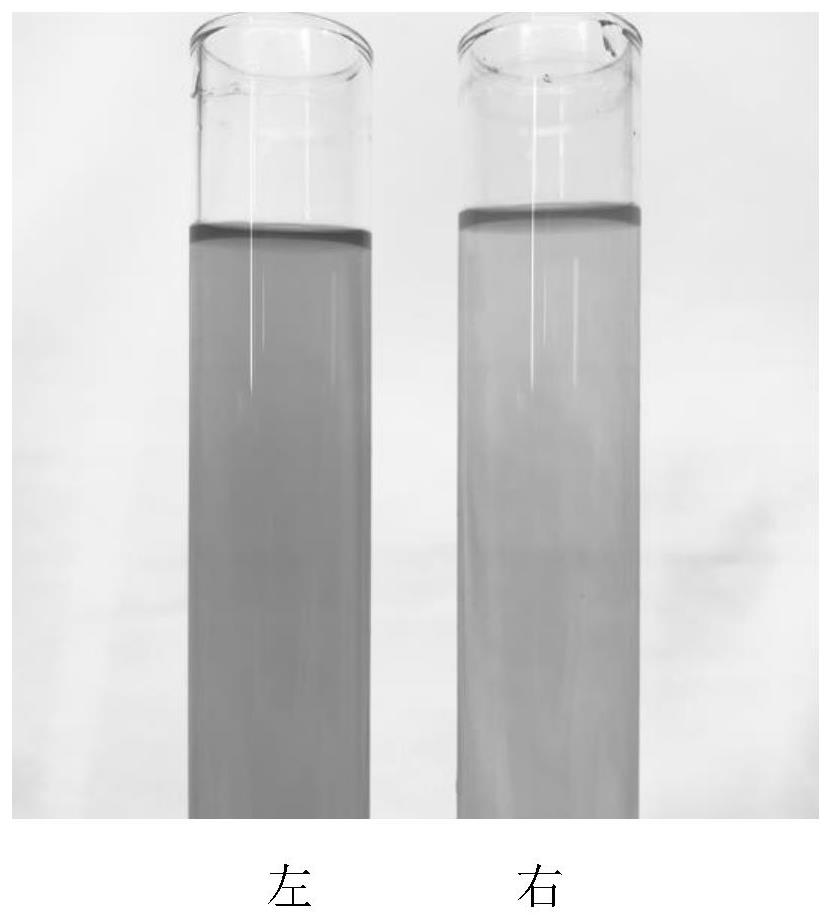

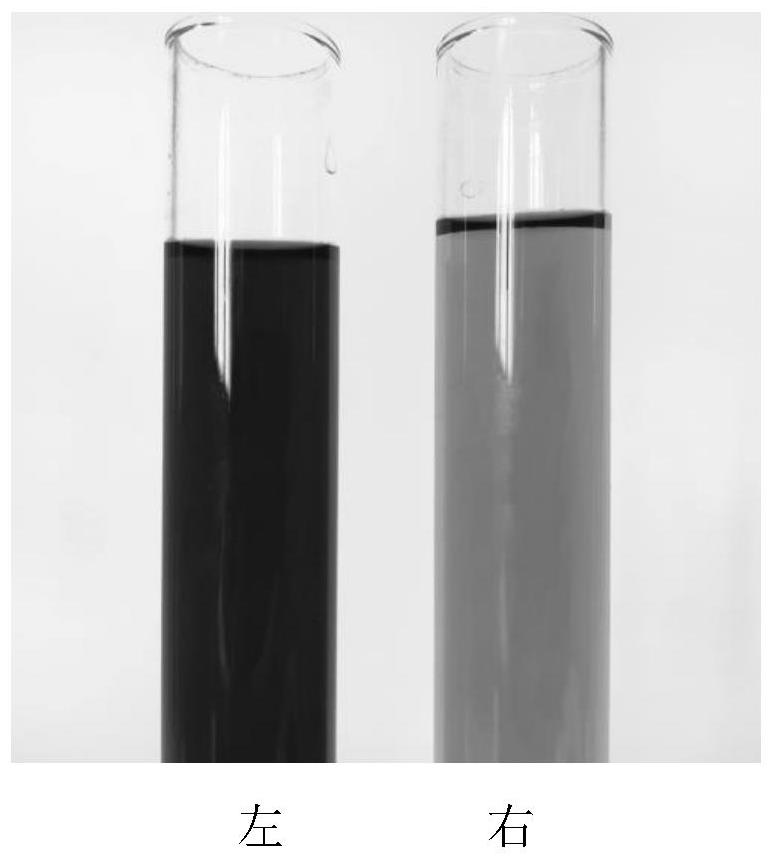

Image

Examples

Embodiment 1

[0071] A nano liquid disperse yellow dye with high washing fastness comprises the following components according to mass percentage:

[0072]

[0073]

[0074] Wherein, the structural formula of alkylphenol polyoxyethylene ether anionic surfactant is as follows:

[0075]

[0076] The method for preparing described high washing fastness nanometer liquid disperse yellow dye comprises the steps:

[0077] (1) Mix alkylphenol polyoxyethylene ether anionic surfactant, dispersant MF and water, and fully disperse it with a high-shear disperser at 1500 rpm for 0.5h; then add C.I. Disperse Yellow 114 filter cake in Pre-disperse at 1500 rpm for 1 hour until there are no obvious particles to obtain a pre-dispersion;

[0078] (2) Filter the pre-dispersion with a filter screen, add glycerin, fatty alcohol defoamer, xanthan gum and butylbenzisothiazolin-3-one to the filtrate, and emulsify at 1500 rpm for 0.5h, Obtain the emulsified mixture;

[0079] (3) Transfer the emulsified mi...

Embodiment 2

[0081] A nano liquid disperse red dye with high washing fastness comprises the following components according to mass percentage:

[0082]

[0083] Wherein, the structural formula of modified styrene polyoxyethylene ether anionic surfactant is as follows:

[0084]

[0085] The method for preparing described high washing fastness nanometer liquid disperse red dye comprises the steps:

[0086] (1) Mix the modified styrene polyoxyethylene ether anionic surfactant, dispersant 85A, and dispersant MF with water, and fully disperse it with a high-shear disperser at 1500 rpm for 1 hour; then add C.I. Disperse Red 376 filter cake was pre-dispersed at 1500 rpm for 3 hours until there were no obvious particles to obtain a pre-dispersion;

[0087] (2) Filter the pre-dispersed liquid with a filter screen, add glycerin, fatty alcohol defoamer, hydroxypropyl methylcellulose and butyl benzisothiazolin-3-one to the filtrate, and turn it at 1500 rpm Emulsified for 1.5h to obtain the emu...

Embodiment 3

[0090] A nano liquid disperse blue dye with high washing fastness comprises the following components according to mass percentage:

[0091]

[0092] Wherein, the structural formula of described polycarboxylate hyperdispersant is as follows:

[0093]

[0094] The method for preparing the described high washing fastness nanometer liquid disperse blue dye may further comprise the steps:

[0095] (1) Mix polycarboxylate hyperdispersant, dispersant 85A with water, and use a high shear disperser to fully disperse at 1500 rpm for 1 hour; then add C.I. Disperse Blue 257 filter cake at 1500 rpm Pre-disperse for 2 hours until there are no obvious particles to obtain a pre-dispersion;

[0096] (2) Filter the pre-dispersion liquid with a strainer, add polyethylene glycol, fatty alcohol defoamer, sodium carboxymethylcellulose and butylbenzisothiazolin-3-one to the filtrate, at 1500 rpm Min is emulsified for 1 hour to obtain the emulsified mixture;

[0097] (3) Transfer the emulsif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com