Cyanate ester resin gel as well as preparation method and application thereof

A technology of cyanate ester resin and type cyanate ester, which is applied in the field of cyanate ester resin, can solve problems such as technology and application development that have not been reported, and achieve the effect of improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

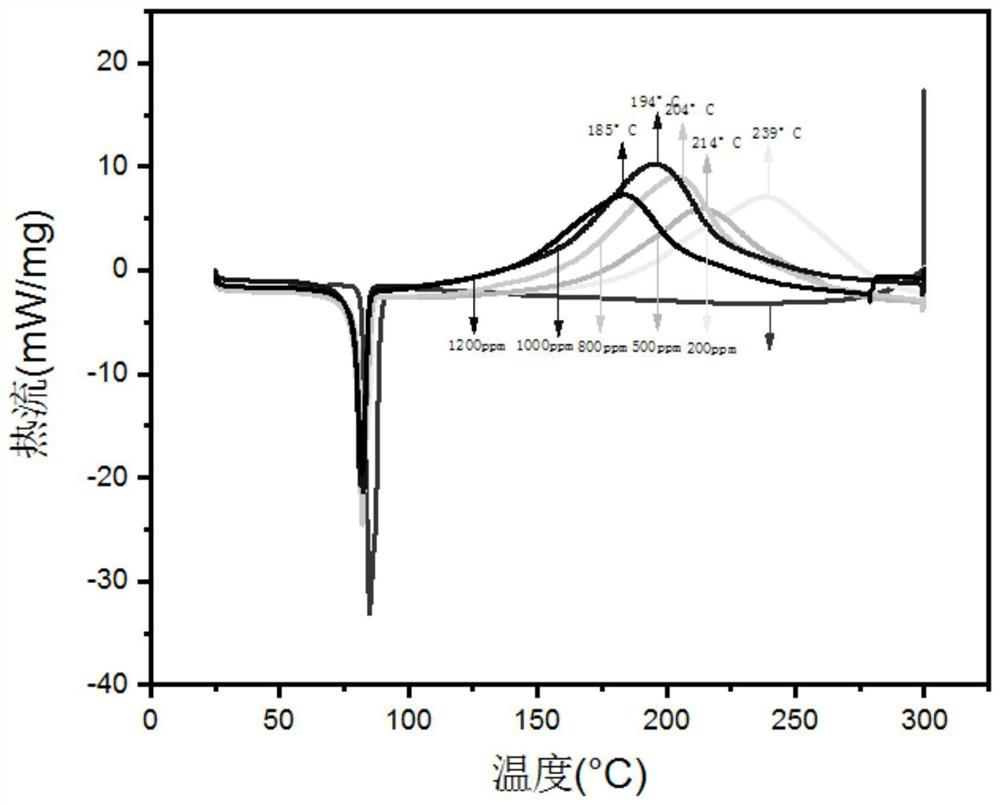

[0044] Add bisphenol A cyanate monomer into dimethylacetamide, heat to 70-80°C, stir while heating to make a homogeneous solution with a solid content of 55%; add dibutyltin dilaurate as a catalyst, The concentration of the catalyst was 200ppm, the reaction was stirred at 150°C for 15min, and the temperature was rapidly cooled to room temperature to obtain a cyanate resin gel (Gel-CE-01).

Embodiment 2

[0046] Add bisphenol A type cyanate monomer into dimethylacetamide, heat to 70-80°C, stir while heating to make a homogeneous solution with a solid content of 50%, add dibutyltin dilaurate as a catalyst, The concentration of the catalyst was 500ppm, the reaction was stirred at 140° C. for 12 minutes, and the temperature was rapidly cooled to room temperature to obtain a cyanate resin gel (Gel-CE-02).

Embodiment 3

[0048] Add bisphenol A cyanate monomer into dimethylacetamide, heat to 70-80°C, stir while heating to make a homogeneous solution with a solid content of 30%, add dibutyltin dilaurate as a catalyst, The concentration of the catalyst was 800ppm, and the reaction was stirred at 150° C. for 11 minutes, and the temperature was rapidly lowered to room temperature to obtain a cyanate resin gel (Gel-CE-03).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com