Graft polymerization induced electricity improving preparation machine for high-elasticity polyvinyl chloride product

A technology of polyvinyl chloride and graft polymerization, which is applied in the field of preparation machines for graft polymerization induction and promotion, which can solve the problems of less recycling of waste gas plastics, insufficient control of rational use, and reduced compactness and elasticity, so as to ensure integrated high efficiency Enhanced performance, safety, and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

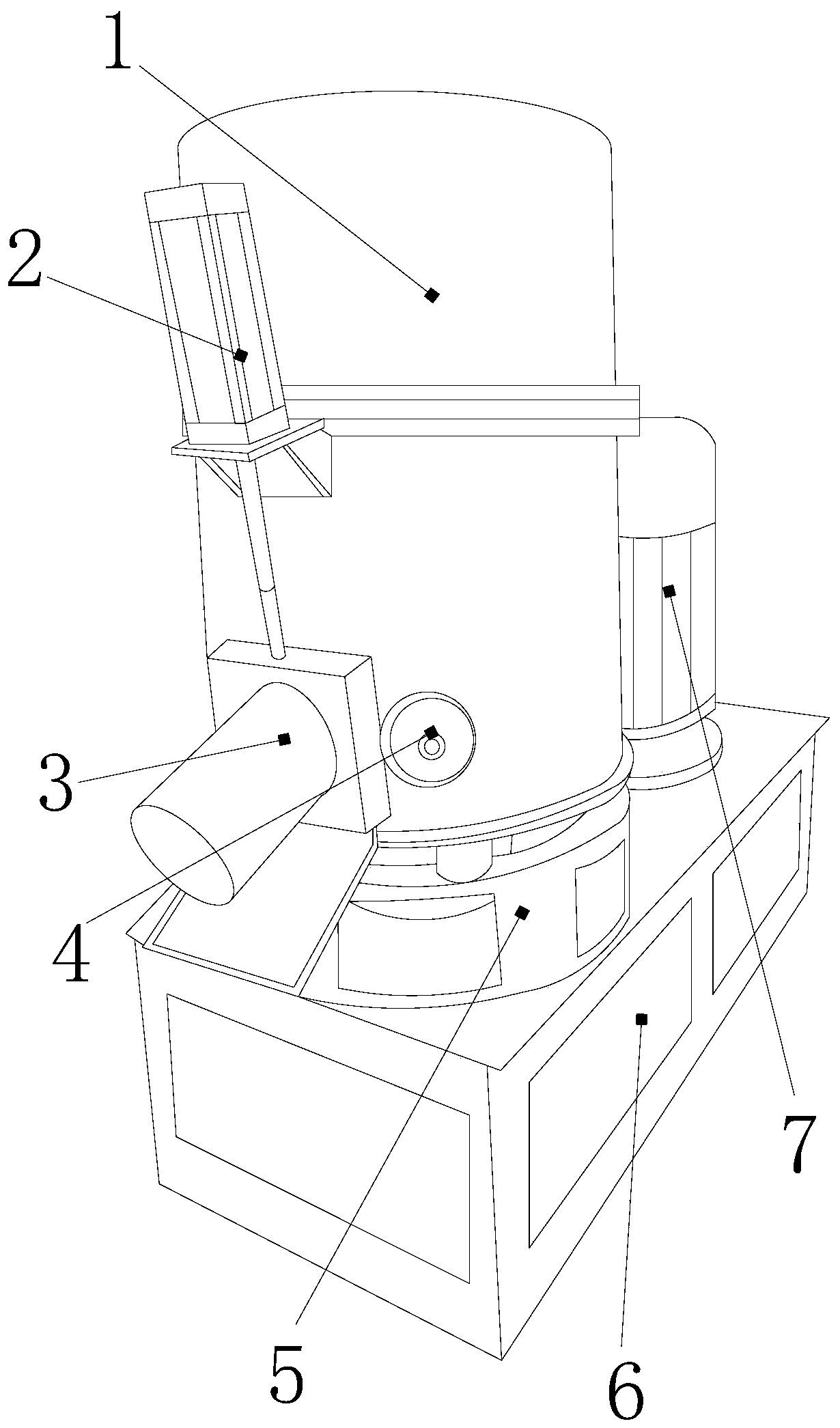

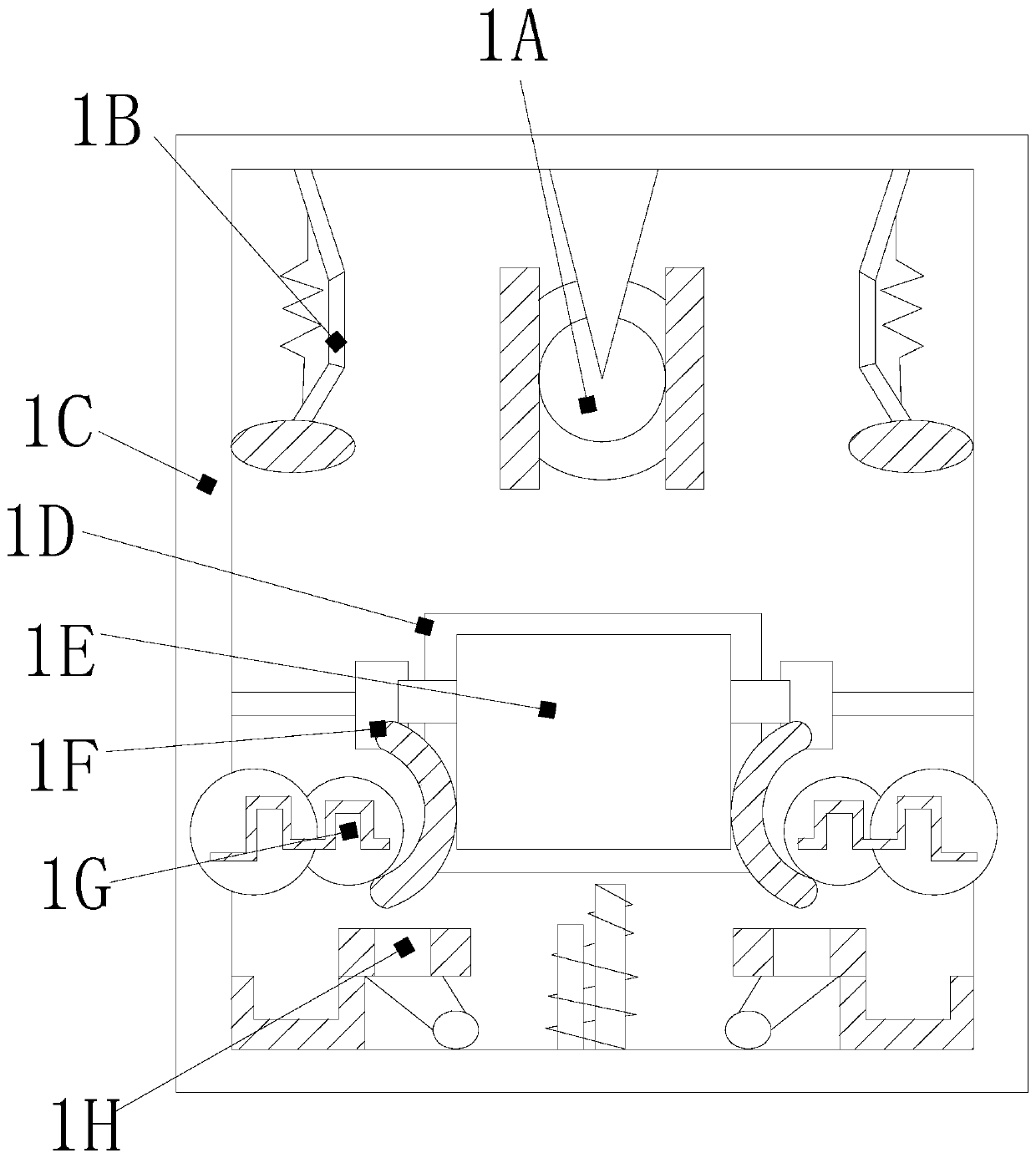

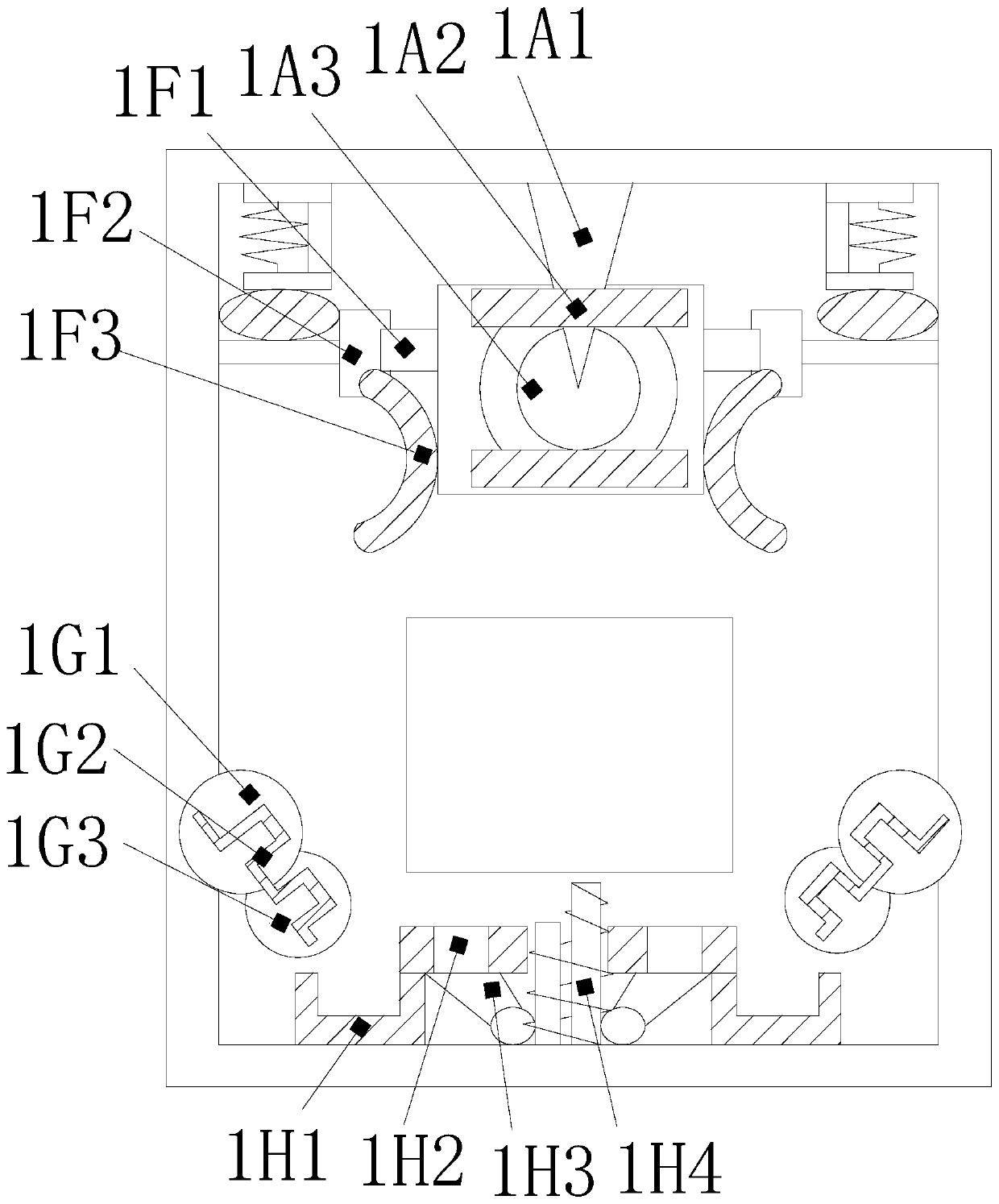

[0033] see Figure 1-Figure 7 , the present invention provides a preparation machine for graft polymerization induction lifting of high elastic polyvinyl chloride products. Frame base 5, raw material extraction box 6, motor 7, the polymer Yuden can 1 is inserted on the top of the frame base 5 and the axis is collinear, the hydraulic cylinder 2 is close to the polymer Yuden tank 1 The front side of the front side, the plunger plate 4 is nested in the front side of the polymer Yuden tank 1 and is on the same vertical plane, the discharge slide 3 is inserted in the front side of the polymer Yuden tank 1 and Interconnected with each other, the motor 7 is inserted and embedded in the rear side of the Polymerized Yuden Can 1, the disc frame base 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com