Lightweight polyurethane elastomer as well as manufacturing method and application thereof

A polyurethane elastomer and lightweight technology, which is applied in the field of polyurethane materials to achieve excellent mechanical properties, ensure lightweight, and reduce density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0067] The preparation method of embodiment and comparative example polyurethane elastomer:

[0068] 1) At 40°C, mix and stir the isocyanate component A and the isocyanate-reactive component B respectively for further use;

[0069] 2) At 40°C, the isocyanate component A and the isocyanate-reactive component B are uniformly mixed by a high-speed mixer, and then poured into a mold at 140°C. After reaction curing molding, demoulding, and aging, light weight can be obtained Quantification of polyurethane elastomers. The raw materials used in Examples and Comparative Examples are listed in Table 1.

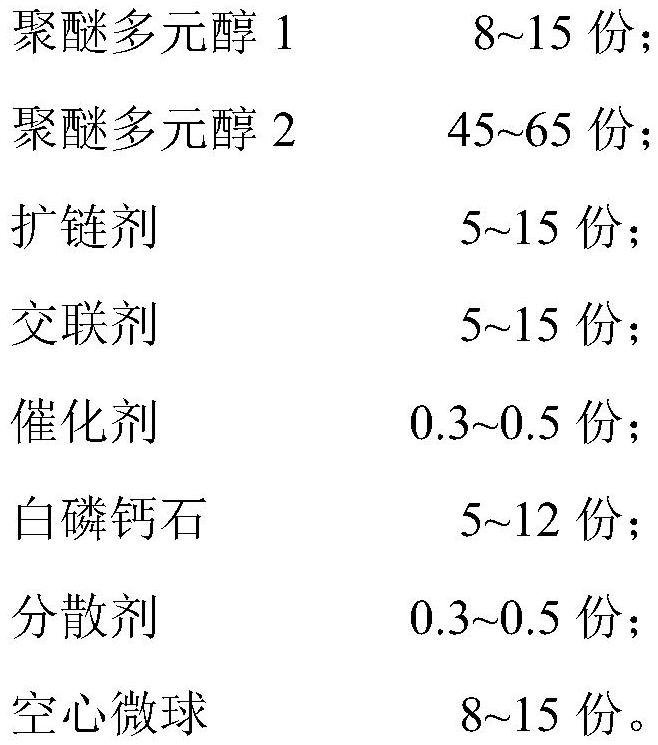

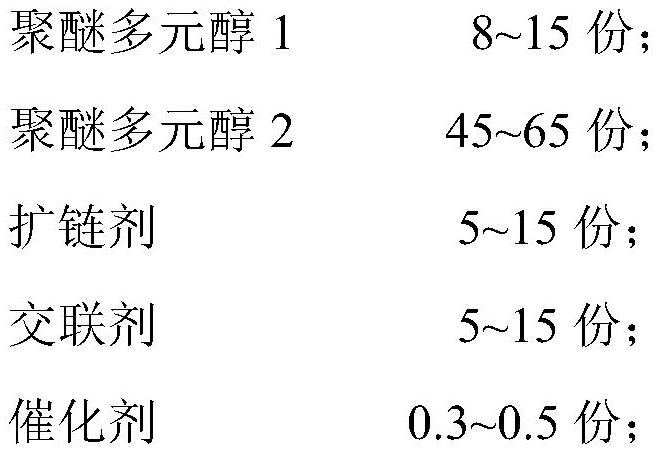

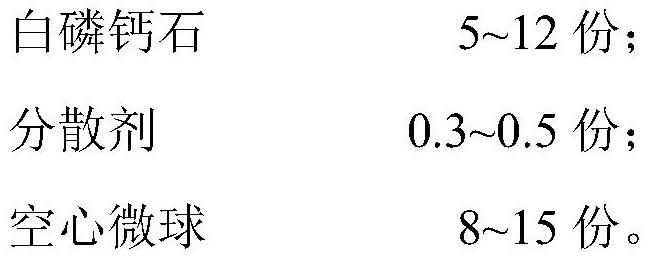

[0070] Table 1 embodiment and comparative example raw material data table (mass parts)

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com