Method for reducing surface cracks of alloy steel, alloy steel and preparation method of alloy steel

A surface crack, alloy steel technology, applied in the workpiece surface treatment equipment, metal rolling, metal rolling and other directions, can solve the problem of "copper embrittlement" that cannot be avoided, and reduce the phenomenon of "copper embrittlement" and "copper embrittlement". , reduce the effect of quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

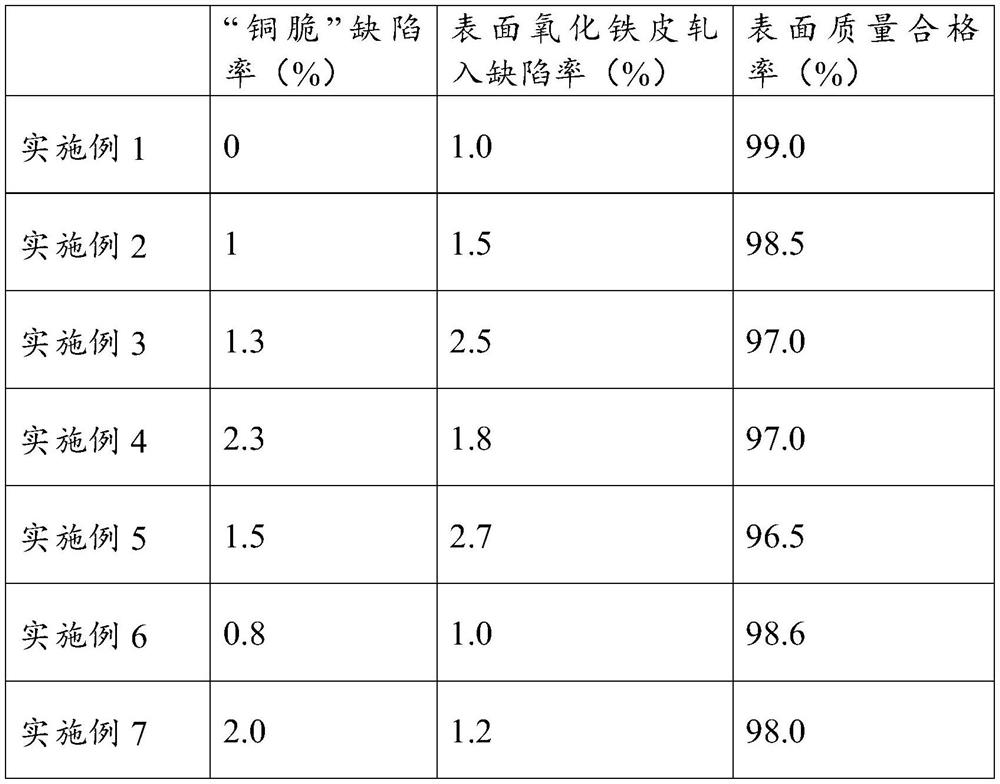

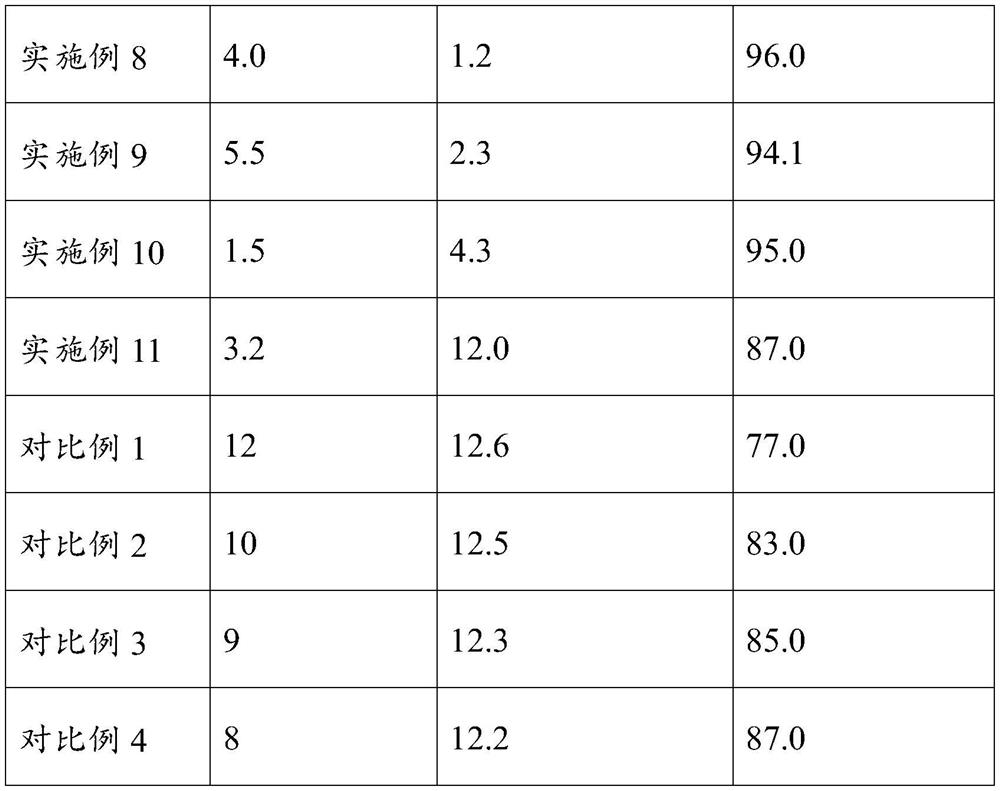

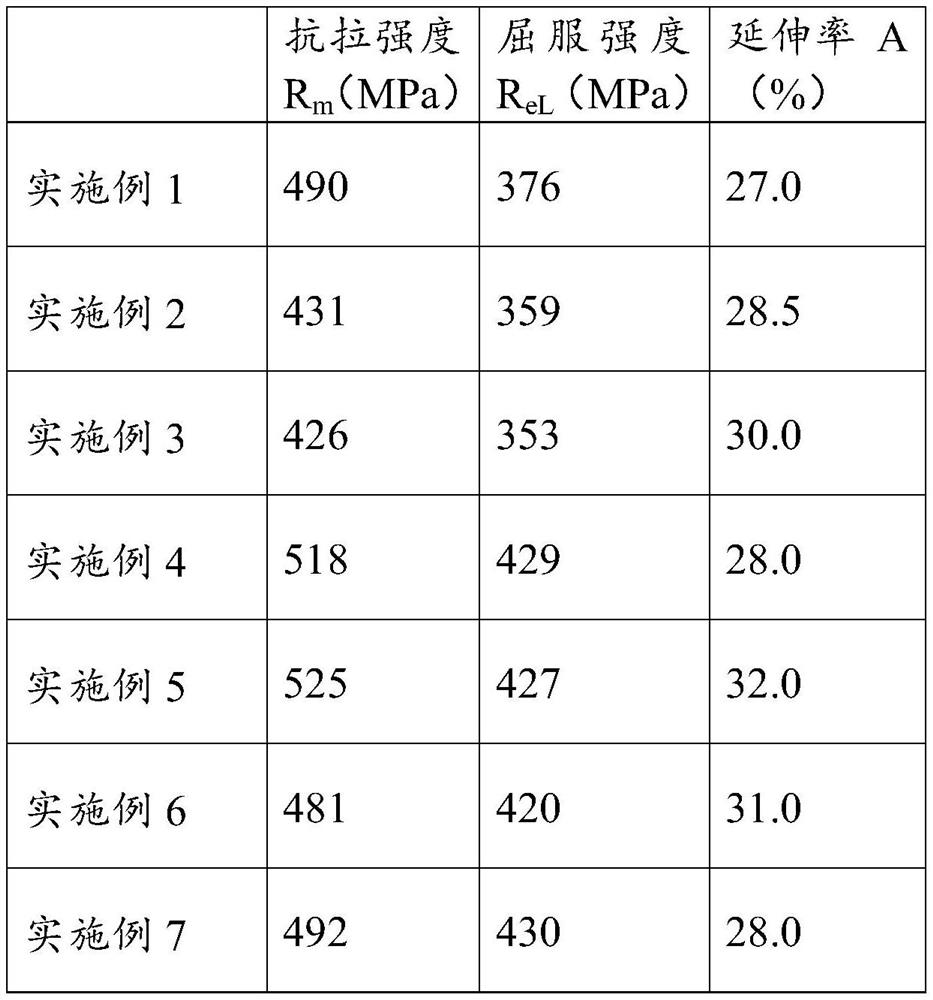

Examples

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of alloy steel, comprises the following steps:

[0041] 1) Pretreatment of molten iron: heating molten iron to 1295°C, using 85% CaO-15% CaF 2 Desulfurizer, add 5.9kg of desulfurizer per ton of iron; insert the stirring head into the molten steel at a depth of 1.2m, and the stirring speed is 90r·min -1 , the stirring time is 7min; the S content of deep desulfurization of molten steel is 0.0080%;

[0042] 2) Converter smelting: Converter charging 170t, including scrap steel 17t, molten iron 153t; blowing oxygen supply intensity 28000Nm 3 h -1 , the single furnace blowing time is 16min, and the end point C of the converter is controlled at 0.04%; 350kg of lime, 1280kg of silicon-manganese alloy, 2120kg of ferrochrome, and 250kg of aluminum-based deoxidizer are sequentially added in post-treatment, and the end point temperature of the converter is 1638°C;

[0043] 3) LF refining: first furnace inlet and outlet...

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of alloy steel, comprises the following steps:

[0054] 1) Pretreatment of molten iron: heating molten iron to 1310°C, using 85% CaO-15% CaF 2 Desulfurizer, add 6.0kg of desulfurizer per ton of iron; insert the stirring head into the molten steel at a depth of 1.25m, and the stirring speed is 85r min -1 , stirring time 8.3min; deep desulfurization of molten steel S content 0.0090%;

[0055] 2) Converter smelting: converter charging 170t, including scrap steel 25.5t, molten iron 144.5t; blowing oxygen supply intensity 28000Nm 3 h -1 , the single furnace blowing time is 14min, and the end point C of the converter is controlled at 0.03%; 350kg of lime, 1260kg of silicon-manganese alloy, 2080kg of ferrochrome, and 295kg of aluminum-based deoxidizer are sequentially added in post-treatment, and the end point temperature of the converter is 1640°C;

[0056] 3) LF refining: first furnace inlet and outlet temperatu...

Embodiment 3

[0066] The present embodiment provides a kind of preparation method of alloy steel, comprises the following steps:

[0067] 1) Hot metal pretreatment: hot metal is heated to 1380°C, using 85% CaO-15% CaF 2 Desulfurizer, add 5.0kg of desulfurizer per ton of iron; insert the stirring head into the molten steel at a depth of 1.3m, and the stirring speed is 100r·min -1 , the stirring time is 7min; the S content of deep desulfurization of molten steel is 0.0065%;

[0068] 2) Converter smelting: Converter charging 170t, controlled scrap ratio 17t, molten iron 153t; blowing oxygen supply intensity 28000Nm 3 h -1 , the single furnace blowing time is 13.2min, and the end point C of the converter is controlled at 0.05%; 350kg of lime, 1290kg of silicon-manganese alloy, 2180kg of ferrochrome, and 260kg of aluminum-based deoxidizer are added in sequence for post-treatment, and the end point temperature of the converter is 1645°C;

[0069] 3) LF refining: the first furnace inlet and out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com