Preparation method of magnetic activated carbon and application of magnetic activated carbon in flue gas demercuration

A magnetic activated carbon and activated carbon technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome and complicated steps, difficult control, and long reaction time, and achieve good dispersion, easy control, and adsorption performance. long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

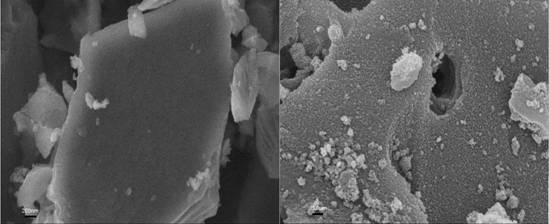

[0027] The preparation method of magnetic activated carbon comprises the steps:

[0028] (1) Weigh activated carbon, soluble iron salt, nickel soluble salt and zinc soluble salt in proportion, dissolve them in absolute ethanol or deionized water, stir well to obtain a mixed solution,

[0029] (2) Calcining the mixed solution obtained in step (1) at 300-500° C. for 1-4 hours in a nitrogen atmosphere, stopping heating, cooling to room temperature in a nitrogen atmosphere, and obtaining magnetic activated carbon.

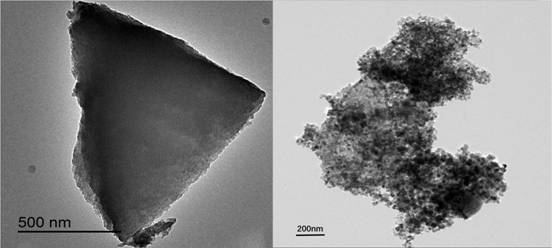

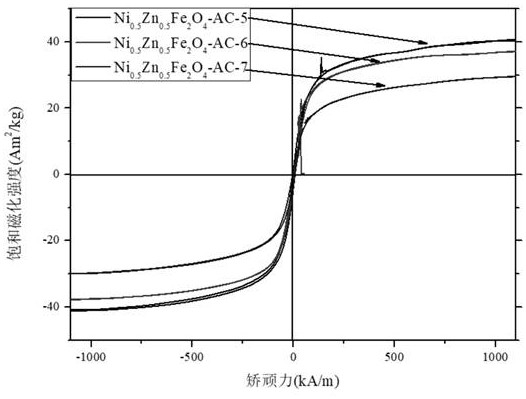

[0030] Further, in step (1), the molar ratio of nickel, zinc and iron is 1:1:4. Under this molar ratio, NiFe 2 o 4 Ni in 2+ Ions are Zn 2+ Partial substitution of ions can generate magnetic nanoparticles Ni 0.5 Zn 0.5 Fe 2 o 4 , Ni 0.5 Zn 0.5 Fe 2 o 4 The saturation magnetization is the largest, compared to NiFe 2 o 4 With better performance and lower cost.

[0031] The mass ratio of iron to activated carbon is 1:5~1:8. Preferably, the mass ratio of iron...

Embodiment 1

[0040] 1. Preparation of Magnetic Activated Carbon Materials

[0041] Take the raw material according to the following weight: iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 6.90g, nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1.24g, zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) 1.26g, activated carbon 4.78g, (Fe:AC=1:5).

[0042] Mix the weighed ferric nitrate nonahydrate, nickel nitrate hexahydrate, and zinc nitrate hexahydrate into absolute ethanol, stir evenly, add activated carbon, and then stir on a magnetic stirrer for a certain period of time to mix uniformly to obtain a mixed solution. In the present invention, the stirring speed is 200 r / min, and the stirring time is 6 h.

[0043] Put the uniformly stirred mixed solution in a tube furnace under a nitrogen atmosphere, raise the temperature to a certain temperature at a certain heating rate and calcinate for a period of time to obtain magnetic activated carbon, which is recorded as Ni 0.5 Zn 0.5 Fe 2 o ...

Embodiment 2

[0050] 1. Preparation of Magnetic Activated Carbon Materials

[0051] Take the raw material according to the following weight: iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 6.90g, nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 1.24g, zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) 1.26g, activated carbon 5.74g, (Fe:AC=1:6).

[0052] Mix the weighed ferric nitrate nonahydrate, nickel nitrate hexahydrate, and zinc nitrate hexahydrate into absolute ethanol, stir evenly, add activated carbon, and then stir on a magnetic stirrer for a certain period of time to mix uniformly to obtain a mixed solution. In the present invention, the stirring speed is 200 r / min, and the stirring time is 6 h.

[0053] The uniformly stirred mixed solution was placed in a tube furnace under a nitrogen atmosphere, and the calcination heating rate was 5°C / min, the calcination temperature was 400°C, and the calcination time was 2 h. After the reaction, the magnetic activated carbon was recorded as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com