Magnetic nanometer material as well as preparation method thereof and application of magnetic nanometer material in radioactive element treatment

A magnetic nanometer and magnetic particle technology, which is applied in the directions of radioactive pollutants, magnetic field/electric field water/sewage treatment, chemical instruments and methods, etc., to achieve the effect of recyclable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Synthesis of Magnetic Iron Oxide Nanoparticles (Magnetic Particles)

[0028] FeCl 3 •6H 2 O (2.16g, 8mmol), sodium citrate (C 6 h 5 o 7 Na 3 • 2H 2O) (4.70g, 16mmol) and urea (1.44g, 24mmol) were added to 120mL of distilled water; after stirring, polyacrylamide (1.2g) was added and stirred vigorously with a magnetic stirrer for 1h. The resulting mixed solution was then transferred to a 200 mL Teflon-lined stainless steel autoclave, and kept at 200° C. for 12 hours. The product was then washed several times with ethanol and deionized water, and then captured by a magnetic field to obtain magnetic particles, referred to as Fe 3 o 4 .

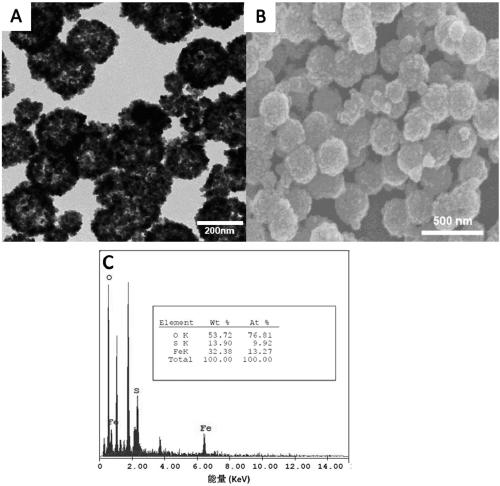

[0029] Characterization of Synthesized Iron Oxide Magnetic Particles: From figure 1 A and figure 1 B, it can be seen that the diameter of the magnetic nanoparticles is about 200nm. figure 1 A is a low-resolution TEM image of magnetic iron oxide nanoparticles. It can be found that the middle of the nanoparticles is tran...

Embodiment 2

[0030] Example 2 Magnetic Composite Nanoparticles with a Core-Shell Structure of Nanoscale Sulfur-Wrapped Iron Oxide

[0031] Coating a layer of nano-sulfur on the surface of magnetic iron oxide particles: Dissolve 26.5 mg of sulfur elemental substance in 5 mL of toluene, and add all the dissolved elemental sulfur to 0.1 M iron ferric oxide nanoparticles (prepared in Example 1) toluene solution ( The mass ratio of magnetic particles to sulfur element is 1:8). The resulting mixed solution was heated to 80 °C and kept at this temperature for 30 min. Subsequently, the mixed solution was cooled to room temperature and absolute ethanol was added to precipitate the nanoparticles. Add the precipitated solution into the centrifuge tube and centrifuge (centrifugation condition is 7000 r / min, 10 min). After centrifugation, pour out the supernatant, add n-hexane and absolute ethanol for ultrasonic cleaning. After repeating the above steps three times, excess toluene was added to disso...

Embodiment 3

[0033] Example 3 Magnetic Composite Nanoparticles Modified by Ligand Molecules

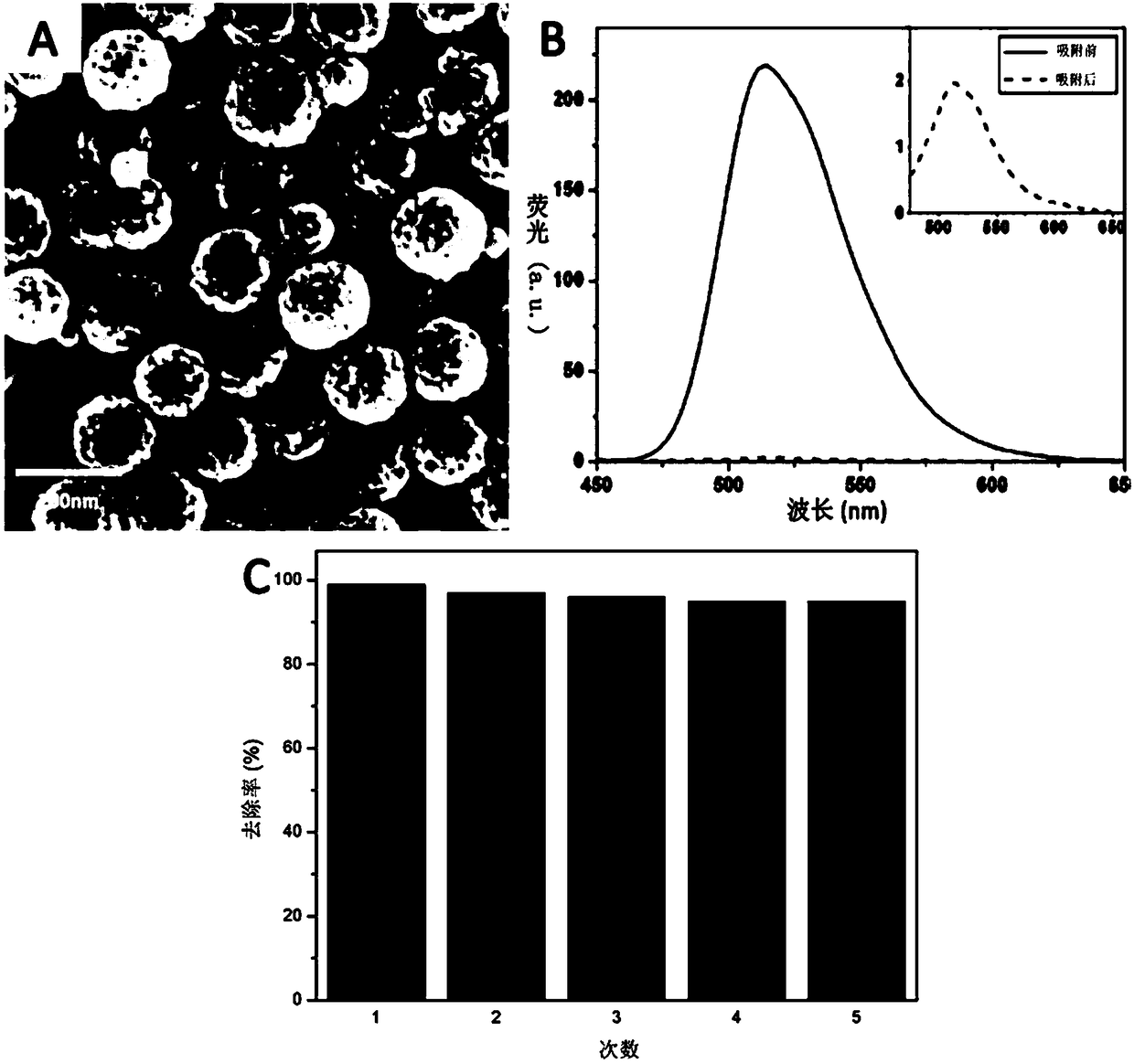

[0034] Synthesize ligand molecules that can specifically bind to radionuclides, and perform water-soluble ligand replacement on oil-phase iron oxide nanoparticles: 10 mg dopamine-bisphosphonate is dissolved in 10 ml H 2 O, and the pH value was adjusted to 5; then mixed with 10 mL of nano-iron oxide (2 mg / mL) in hexane (mass ratio of magnetic particles to dopamine-bisphosphonate 2:1), and then treated with ultrasonic waves for 30 minutes . The aqueous phase was then separated and the product was rinsed three times with 10 mL of hexane. Iron oxide magnetic nanoparticles (Fe 3 o 4 -BiP), that is, magnetic nanomaterials. By TEM ( image 3 A) Characterization confirms that the reaction product is indeed iron oxide magnetic nanoparticles with dopamine-bisphosphate ligand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com