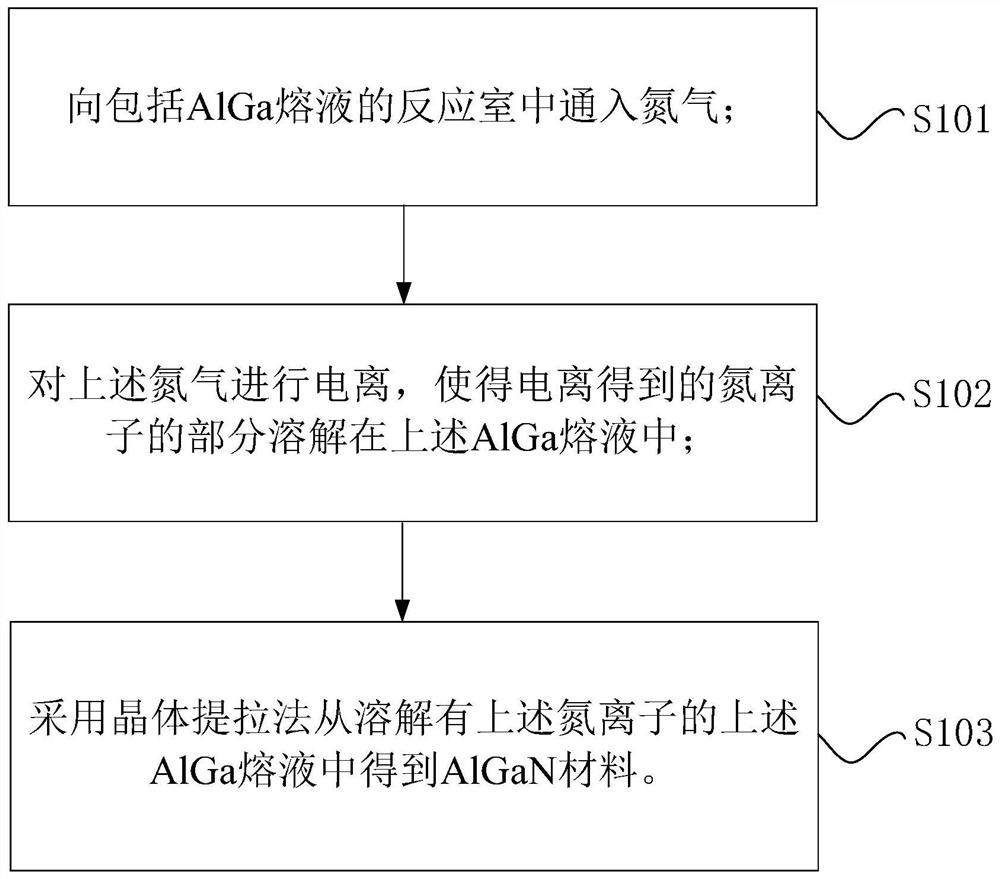

Growth method of AlGaN material

A growth method and solution technology, applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of slow preparation speed and high preparation cost of AlGaN materials, and achieve fast preparation speed, which is conducive to large-scale industrial production The effect of production preparation and preparation cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

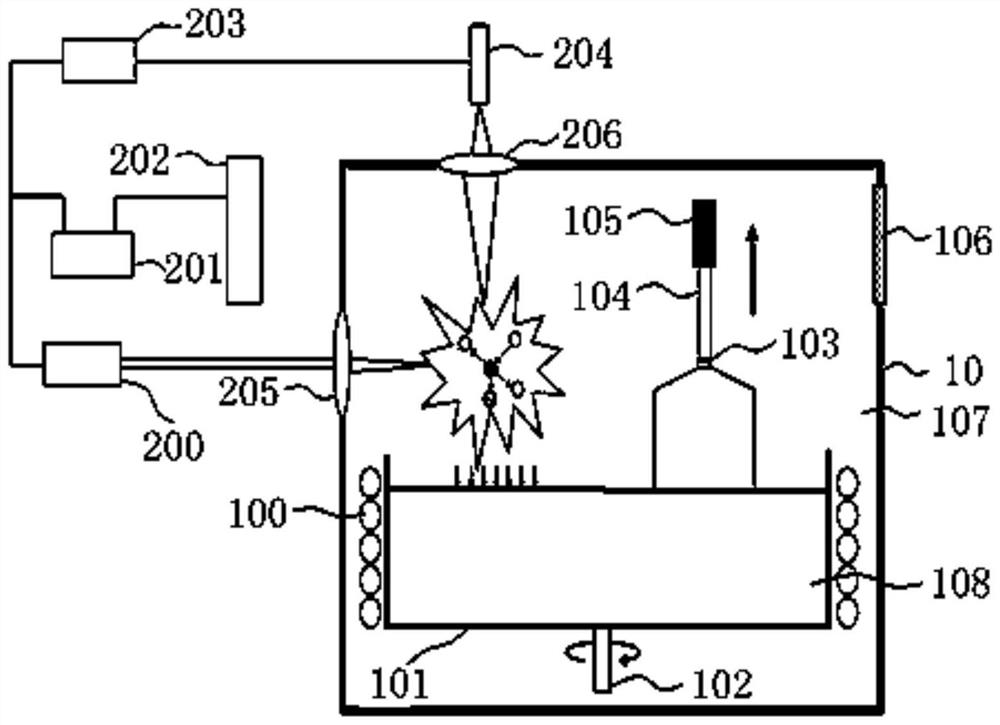

[0062] Provide figure 2 The growth device of the ALGAN material is specifically as follows:

[0063] Step 1: The melting point of 0.99999% of the purity of 99.9999% is provided, and the melting point of Al is 660 ° C, and the melting point of Ga is 29.8 ° C. The crucible made of quartz material was selected, and the metal Al and Ga of the molar volume ratio of 2: 8 were placed in the crucible. The order in which the placement can be paved in a layer of Al powder in the crucible, and then some metal Ga small pieces are placed thereon, and some boron oxide substances are placed around them. After the material is placed, the reaction chamber is closed, and the pressure in the reaction chamber is pumped to the vacuum state, the vacuum is 1 × 10 -6 PA;

[0064] Step 2: Power on the heating coil around the crucible, so that the internal temperature of the crucible is raised to 750 ° C. The Al powder and metal Ga small pieces in the crucible began to melt. At this time, slowly rotate the...

Embodiment 2

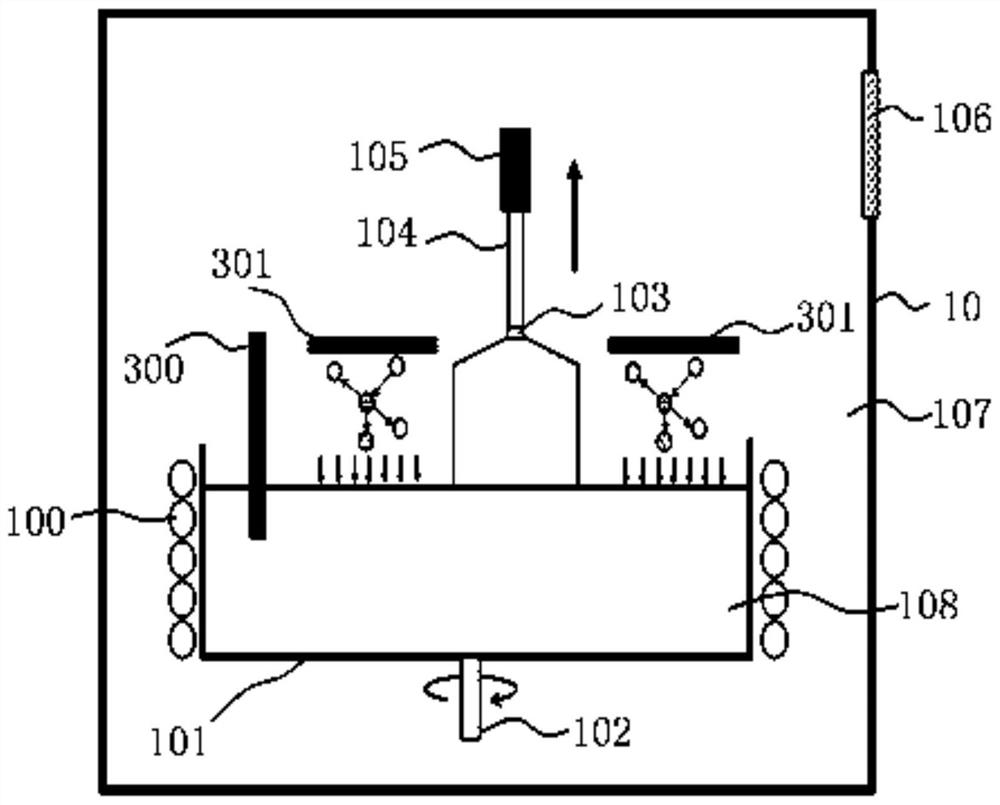

[0070] Provide image 3 The growth device of the ALGAN material is specifically as follows:

[0071] Step 1: Provide aluminum (Al) powder and metal gallium (Ga) with a purity of 99.9999%. The crucible made of quartz material was selected, and the metal Al powder and Ga block of 1: 9 were placed in the crucible. The order in which the placement can be paved in a layer of Al powder in the crucible, and then placed some metal Ga small pieces thereon, and then add a little boron oxide in the edge of the crucible (B 2 O 3 . After the material is placed, the reaction chamber is closed, and the air pressure in the reaction chamber is smashed into a vacuum state, the vacuum is 1 × 10 -5 PA;

[0072] Step 2: Power on the heating coil around the crucible to increase the internal temperature of the crucible to 700 ° C. The Al powder and metal Ga small pieces in the crucible began to melt. At this time, slowly rotate the rotary rod at the bottom of the crucible, and the speed of rotation is 5 ...

Embodiment 3

[0078] Provide Figure 4 The growth device of the ALGAN material is specifically as follows:

[0079]Step 1: The melting point of 0.99999% of the purity of 99.9999% is provided, and the melting point of Al is 660 ° C, and the melting point of Ga is 29.8 ° C. The crucible made of quartz material was selected, and the metal Al and Ga of the molar ratio of 3: 7 were placed in the crucible. The order in which the placement can be paved in a layer of Al powder in the crucible, and then some metal Ga small pieces are placed thereon, and some boron oxide substances are placed around them. After the material is placed, the reaction chamber is closed, and the pressure in the reaction chamber is pumped to the vacuum state, the vacuum is 2 × 10 -6 PA;

[0080] Step 2: Power on the heating coil around the crucible, so that the internal temperature of the crucible is raised to 750 ° C. The Al powder and metal Ga small pieces in the crucible began to melt. At this time, slowly rotate the rotary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser intensity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com