Wear-resistant antifouling hardened film and preparation method thereof

A hardened film and anti-fouling technology, which is applied in coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc., can solve the problems of reducing surface performance, increasing brittleness of hardened film, and decreasing light transmittance of hardened film, so as to avoid Effect of warpage and embrittlement, surface hardness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

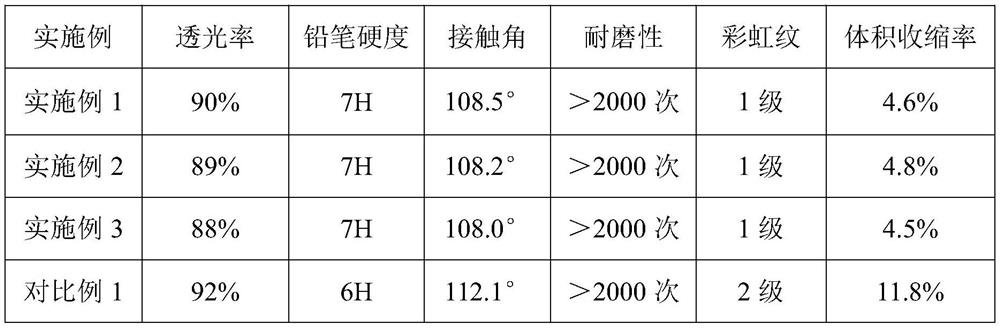

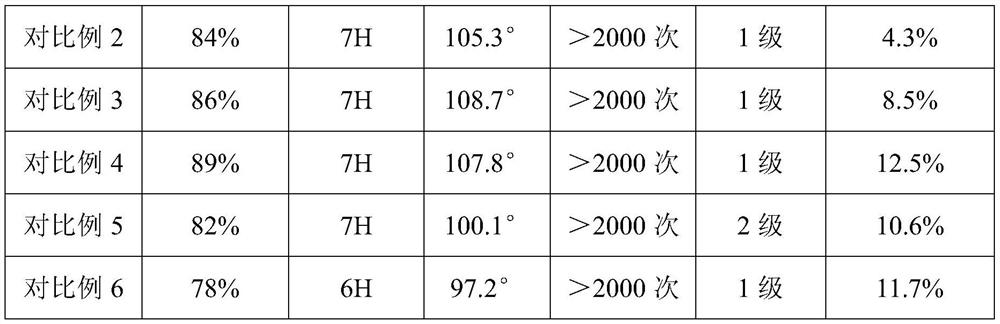

Examples

Embodiment 1

[0030] Step 1: (1) Dissolve 17g of tannic acid in 15mL of anhydrous ethanol-butyl acetate mixed solvent with a volume ratio of 1:1, add 0.05g of hydroquinone and 0.32g of triethylamine, and disperse evenly; Set the temperature to 95° C., stir and drop allyl glycidyl ether, and react for 32 hours to obtain tannic acid-based acrylate. (2) ultrasonically disperse the acrylate monomer in a mixed solvent of ethyl acetate and acetone with a volume ratio of 2:1, add nano-titanium dioxide; then add octavinylsilsesquioxane, photoinitiator, and photosensitive resin in sequence, Stir and homogenize at 1200rmp; obtain a hardened coating liquid.

[0031] Step 2: Put one side of the polyethylene terephthalate film under a UV lamp with a wavelength of 254nm, and set the light intensity to 15mW / cm 2 , light treatment for 15 minutes; evenly coat the hardened coating solution, also under the 254nm ultraviolet lamp, set the low light intensity to 20mW / cm 2 , irradiate for 5-8 minutes; set the ...

Embodiment 2

[0034]Step 1: (1) Dissolve 17g of tannic acid in 15mL of anhydrous ethanol-butyl acetate mixed solvent with a volume ratio of 1:1, add 0.05g of hydroquinone and 0.32g of triethylamine, and disperse evenly; Set the temperature to 95° C., stir and drop allyl glycidyl ether, and react for 35 hours to obtain tannic acid-based acrylate. (2) ultrasonically disperse the acrylate monomer in a mixed solvent of ethyl acetate and acetone with a volume ratio of 2:1, add nano-titanium dioxide; then add octavinylsilsesquioxane, photoinitiator, and photosensitive resin in sequence, Stir and homogenize at 1000rmp; obtain a hardened coating liquid.

[0035] Step 2: Put one side of the polyethylene terephthalate film under a UV lamp with a wavelength of 254nm, and set the light intensity to 15mW / cm 2 , light treatment for 15 minutes; evenly coat the hardened coating solution, also under the 254nm ultraviolet lamp, set the low light intensity to 10mW / cm 2 , irradiated for 8 minutes; set the hi...

Embodiment 3

[0038] Step 1: (1) Dissolve 17g of tannic acid in 15mL of anhydrous ethanol-butyl acetate mixed solvent with a volume ratio of 1:1, add 0.05g of hydroquinone and 0.32g of triethylamine, and disperse evenly; Set the temperature to 100° C., stir and add allyl glycidyl ether dropwise, and react for 30 hours to obtain tannic acid-based acrylate. (2) ultrasonically disperse the acrylate monomer in a mixed solvent of ethyl acetate and acetone with a volume ratio of 2:1, add nano-titanium dioxide; then add octavinylsilsesquioxane, photoinitiator, and photosensitive resin in sequence, Stir and homogenize at 1500rmp; obtain a hardened coating liquid.

[0039] Step 2: Put one side of the polyethylene terephthalate film under a UV lamp with a wavelength of 254nm, and set the light intensity to 15mW / cm 2 , light treatment for 18 minutes; evenly coat the hardened coating solution, also under the 254nm ultraviolet lamp, set the low light intensity to 30mW / cm 2 , irradiated for 5 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com