Preparation method of gallium nitride epitaxial structure

An epitaxial structure, gallium nitride technology, applied in the field of preparation of gallium nitride epitaxial structure, can solve problems such as poor heat transfer capability, achieve the effects of reducing thermal resistance, shortening transmission distance, and reducing interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention provides a method for preparing a gallium nitride epitaxial structure, which uses TMAL, TMGA and NH. 3 As the source, gallium (Ga) source and nitrogen (N) source, H 2 Or N 2 As the carrier gas.

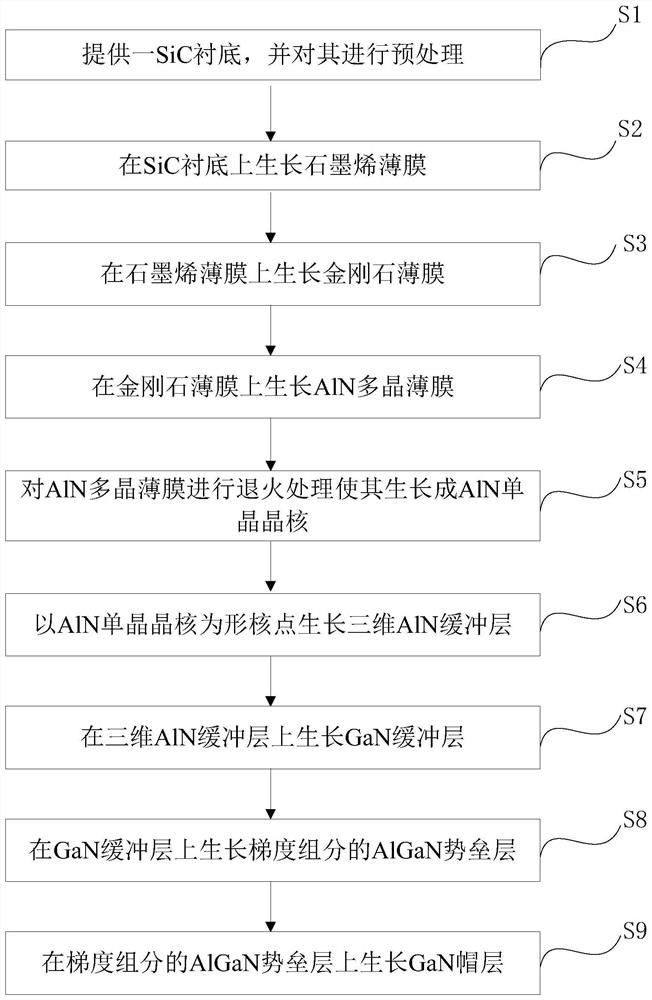

[0057] See Figures 1 to 10 The preparation method of the gallium nitride epitaxial structure of the present invention includes at least the following steps:

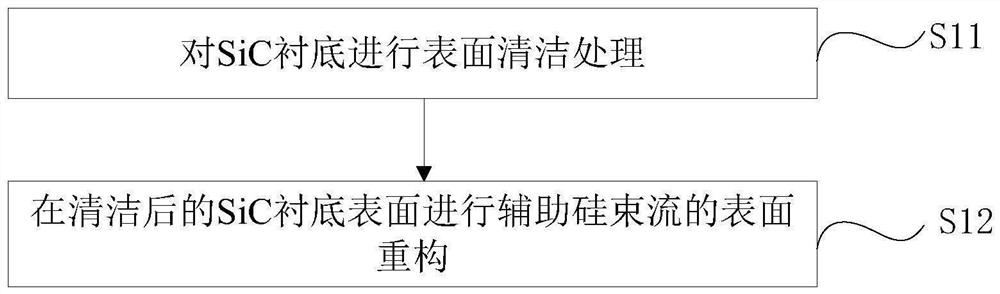

[0058] S1, a SiC substrate 1 is provided, and the SiC substrate 1 is pretreated;

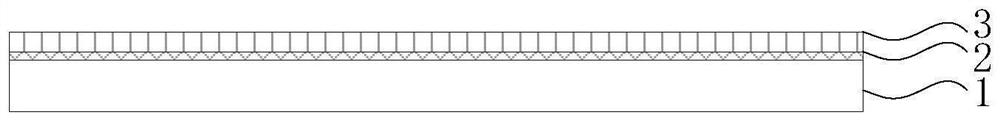

[0059] S2, grown graphene film 2 on the SiC substrate 1 after the pretreatment;

[0060] S3, grown diamond film 3 on the graphene film 2;

[0061] S4 growth AlN polycrystalline film 4 on diamond film 3;

[0062] S5, annealing the ALN polycrystalline film 4 to grow into AlN single crystal nucleus 5;

[0063] S6, the three-dimensional AlN buffer layer 6 is grown by AlN single crystal nucleation 5;

[0064] S7 grows GaN buffer layer 7 on three-dimensional AlN buffer layer 6;

[0065] S8, the Alga barrier layer 8 of the gradie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com