Material with Zn-Cu-Ti alloy coating and preparation method and application thereof

A zn-cu-ti and alloy coating technology, which is applied in metal material coating technology, coating, medical science, etc., can solve the problems of expensive equipment, poor wrapping performance and long production cycle of laser cladding method, and achieve Suitable for large-scale industrial production, high coating bonding strength, and high coating bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

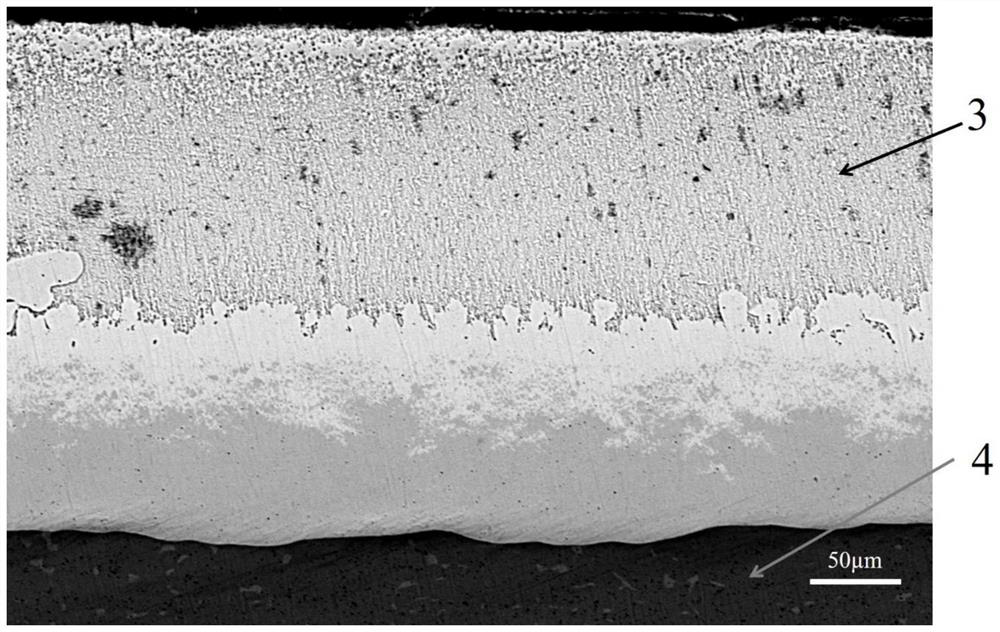

[0032] The preparation method of the material with Zn-Cu-Ti alloy coating provided in the embodiment of the present application includes: placing the titanium substrate in a zinc-copper alloy melt at 435°C to 520°C for immersion plating, through which the titanium element in the titanium substrate The diffusion reaction forms a Zn-Cu-Ti alloy coating on the surface of the titanium substrate, and the Zn-Cu-Ti alloy coating includes a Zn-Cu-Ti free solidification layer.

[0033] The Zn-Cu-Ti free solidification layer involved in this application is different from the free solidification layer in the general sense. The Zn-Cu-Ti free solidification layer involved in this application refers to that after a small amount of titanium enters the zinc-copper melt, it is separated from the zinc-copper melt. The coating formed by the free solidification of zinc and copper melts together.

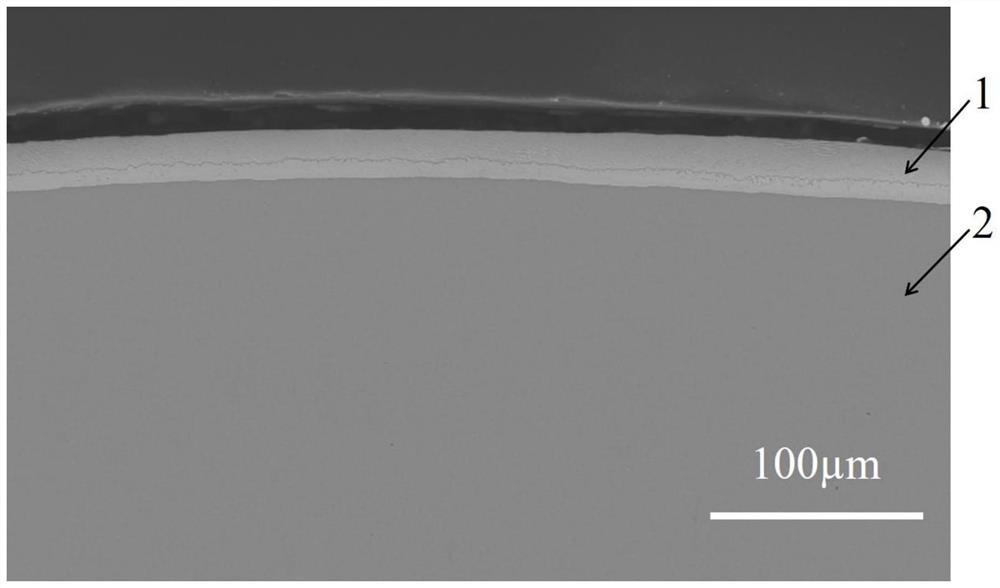

[0034] Such as figure 1 said, figure 1 It is a microscopic cross-sectional view of a material with...

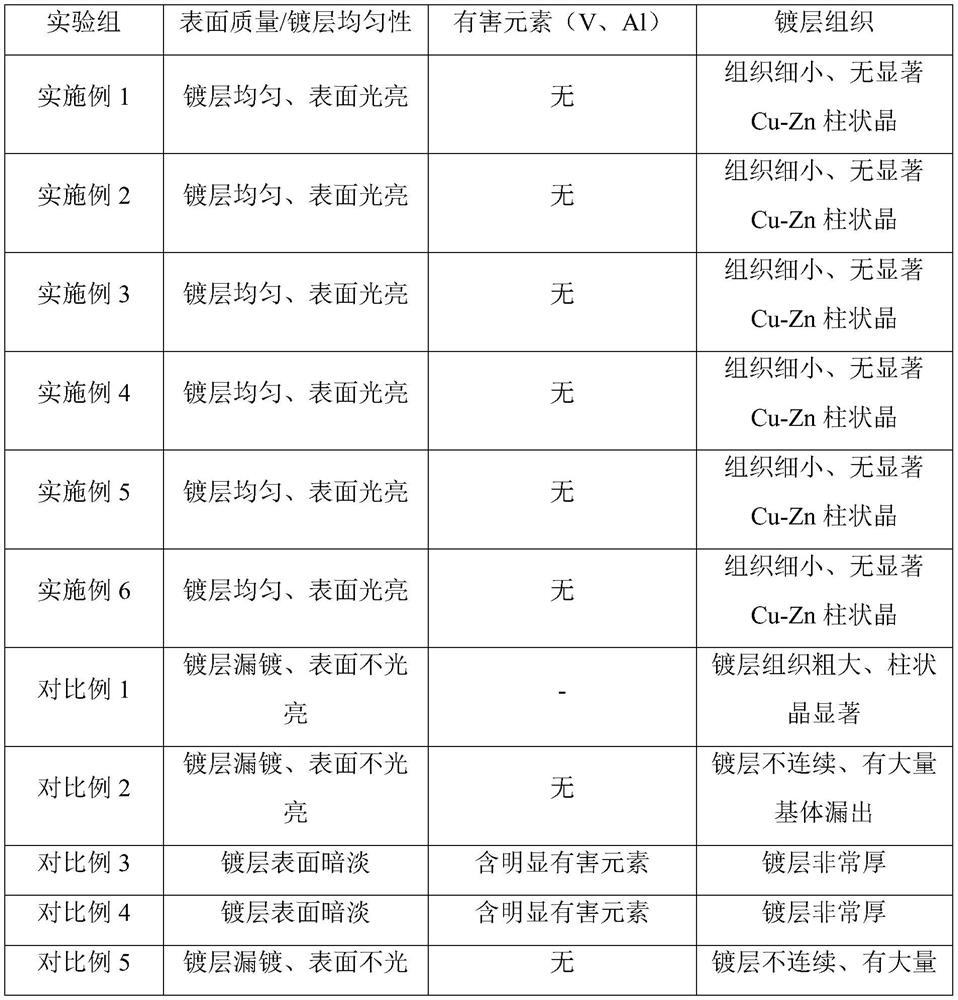

Embodiment 1

[0058] The material with Zn-Cu-Ti alloy coating that present embodiment provides, its preparation method is:

[0059] The pure titanium workpiece substrate (φ5mm×20mm) is alkaline washed. The alkaline washing solution is NaOH solution with a mass concentration of 15%, and the temperature of the alkaline washing solution is 60°C;

[0060] Wash with water at room temperature after alkali washing;

[0061] After washing with water at room temperature, carry out pickling at room temperature, and the pickling solution is 15% HNO in mass concentration 3 and 5% HF mixture, pickling time is 60s;

[0062] Rinse at room temperature again after pickling;

[0063] Dry with cold air after rinsing;

[0064] Place the surface-dried pure titanium workpiece substrate in a zinc-copper alloy melt at a temperature of 435° C., wherein the copper content is 0.5% and dip-plat for 10 seconds, then take it out and water-cool it.

[0065] The total thickness of the alloy coating on the surface of ...

Embodiment 2

[0067] The material with Zn-Cu-Ti alloy coating that present embodiment provides, its preparation method is:

[0068] The pure titanium workpiece substrate (φ5mm×20mm) is alkaline washed. The alkaline washing solution is NaOH solution with a mass concentration of 15%, and the temperature of the alkaline washing solution is 60°C;

[0069] Wash with water at room temperature after alkali washing;

[0070] After washing with water at room temperature, carry out pickling at room temperature, and the pickling solution is 15% HNO in mass concentration 3 and 5% HF mixture, pickling time is 60s;

[0071] Rinse at room temperature again after pickling;

[0072] Dry with cold air after rinsing;

[0073] Place the surface-dried pure titanium workpiece substrate in a zinc-copper alloy melt at a temperature of 460°C, wherein the copper content is 3% and dip-plat for 10s, then take it out and water-cool it.

[0074] The total thickness of the alloy coating on the surface of the pure ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com