Saturated heterochain electrolyte and preparation and application thereof

A technology of electrolytes and heterochains, applied in the field of saturated heterochain electrolytes, can solve problems such as correlation or deducibility uncertainty, and achieve the effects of inhibiting electrolyte decomposition, improving electrochemical performance, and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: raw material

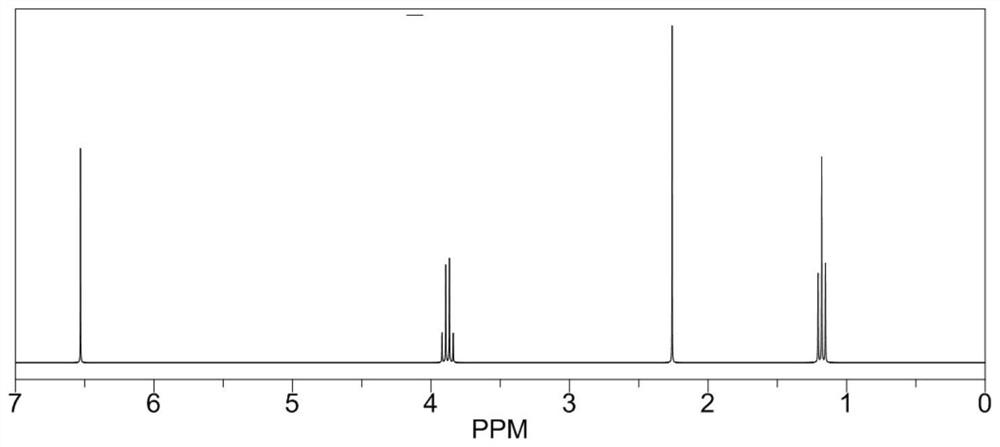

[0061] Preparation method: under argon atmosphere, the raw material (methylaminodiyl) bis(ethoxymethanol) (1.79g, 0.01mol) and boron trifluoride etherate complex (2.98g, 0.021mol) were dissolved in 15ml of ethyl ether Mix evenly in glycol dimethyl ether, and react at room temperature for 12 hours. The resulting mixed solution was dried under reduced pressure at 30° C. and a vacuum of about −0.1 MPa to remove the solvent to obtain an intermediate. Add 14ml of butyllithium hexane solution (c=1.6mol / L) to the intermediate, stir and react at room temperature for 6 hours, and dry under reduced pressure at 40°C and vacuum degree of about -0.1MPa to obtain the crude product Washed 3 times with cyclohexane, filtered and dried to obtain the product M1. The yield was 85%, NMR as figure 1 shown.

Embodiment 2

[0062] Embodiment 2: raw material

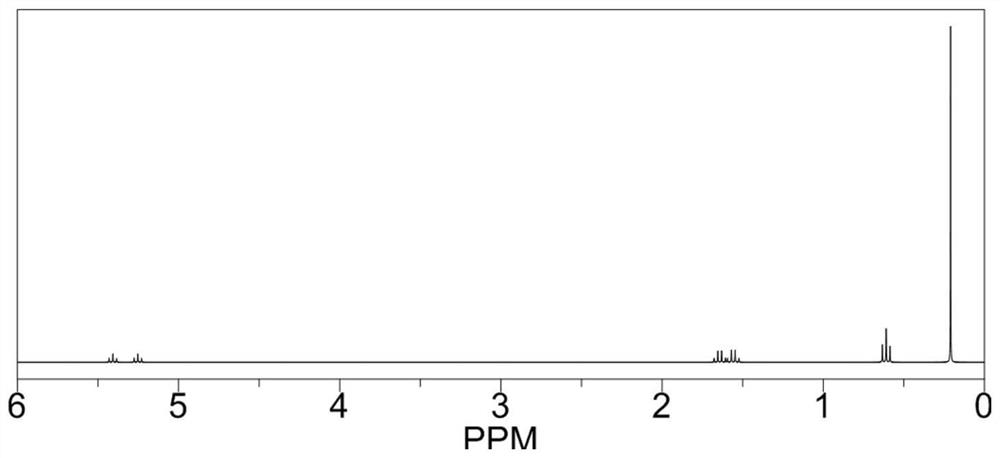

[0063] Preparation method: Under a nitrogen atmosphere, take 0.012mol of the raw material and lithium methoxide (0.76g, 0.02mol), mix well with 20ml of methanol, and react at room temperature for 8 hours. The obtained mixed solution was dried under reduced pressure at 40° C. and a vacuum degree of about -0.1 MPa to remove the solvent to obtain an intermediate. Boron trifluoride tetrahydrofuran complex (3.07g, 0.022mol) was added to the intermediate, stirred at room temperature for 6 hours, and the resulting mixture was dried under reduced pressure at 40°C and a vacuum of about -0.1MPa to obtain The solid was washed three times with isopropyl ether, filtered and dried to give the product M2. Yield 77%, NMR as figure 2 shown.

Embodiment 3

[0064] Embodiment 3: raw material

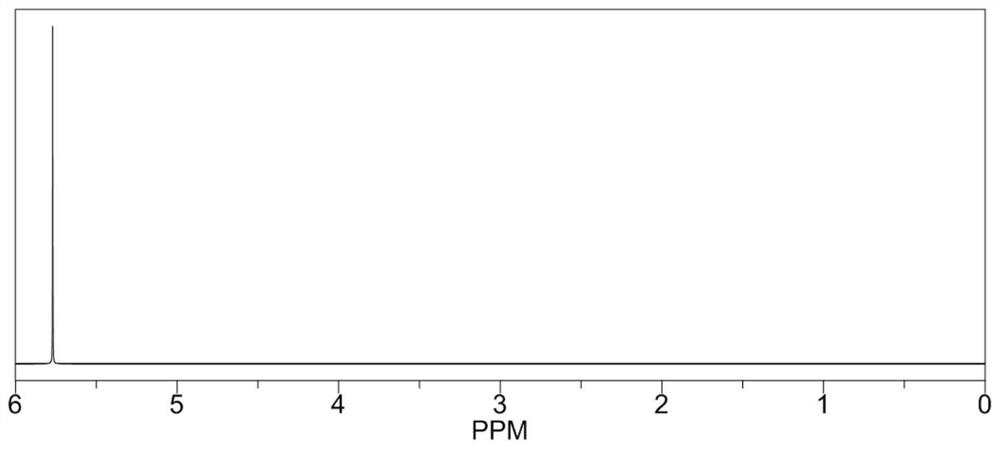

[0065] Preparation method: mix the raw materials bis(hydroxymethyl)peroxide (0.94g, 0.01mol) and boron trifluoride etherate complex (2.98g, 0.021mol) in 15mlTHF in a glove box, and react at room temperature for 12 hours . The resulting mixed solution was dried under reduced pressure at room temperature and a vacuum of about -0.1 MPa to remove the solvent to obtain an intermediate. Lithium ethoxide (1.04g, 0.02mol) was dissolved in 10ml of ethanol and added to the intermediate, stirred at room temperature for 6 hours, and the resulting mixture was dried under reduced pressure at 40°C and a vacuum of about -0.1MPa to obtain The solid was washed three times with isopropyl ether, filtered and dried to give the product M3. The yield was 85%, NMR such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com