Novel energy-saving drying furnace for deep processing of glass

An energy-saving glass and deep-processing technology, which is applied in the field of drying furnaces for new-type energy-saving glass deep processing, can solve problems such as the failure to reach the production temperature, the temperature drop of the drying furnace, and the waste discharge function is not installed, so as to avoid the temperature drop in the furnace, Improve the effect of hot air convection and rapid curing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

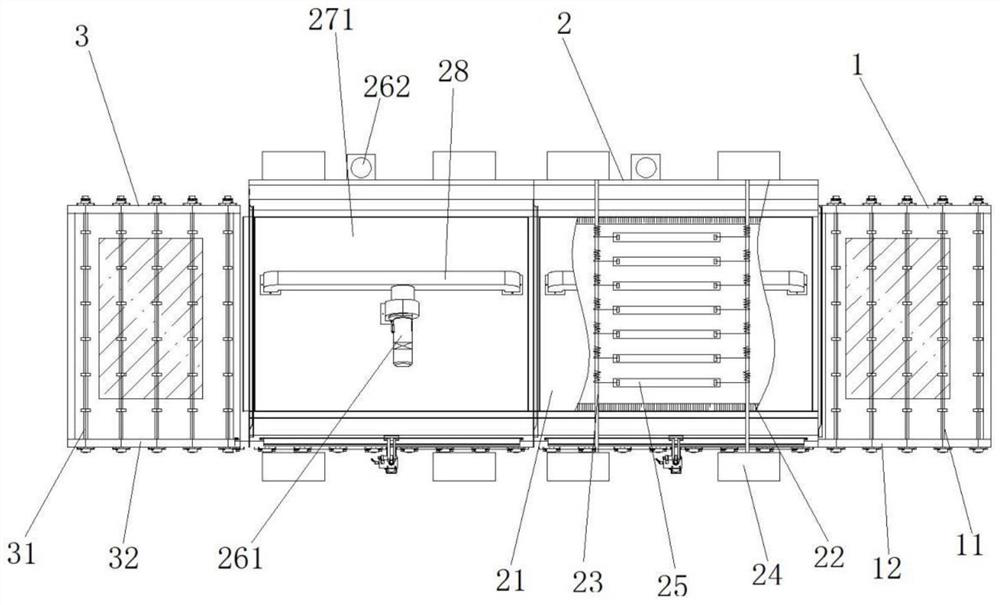

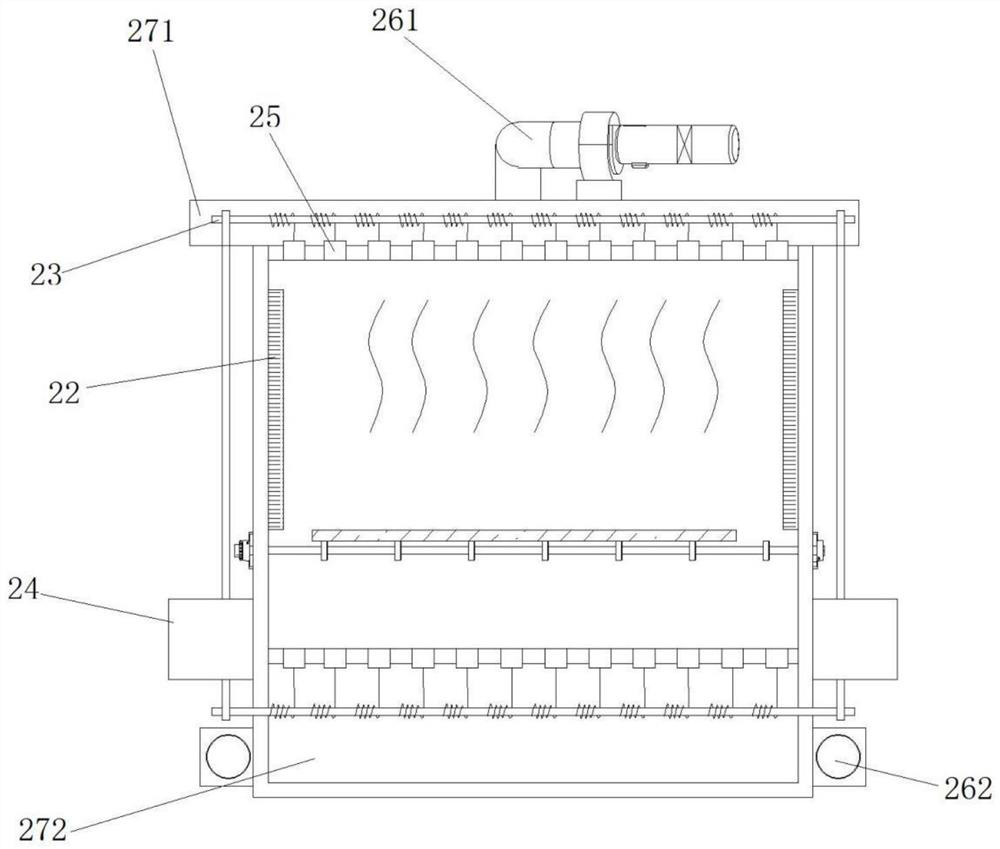

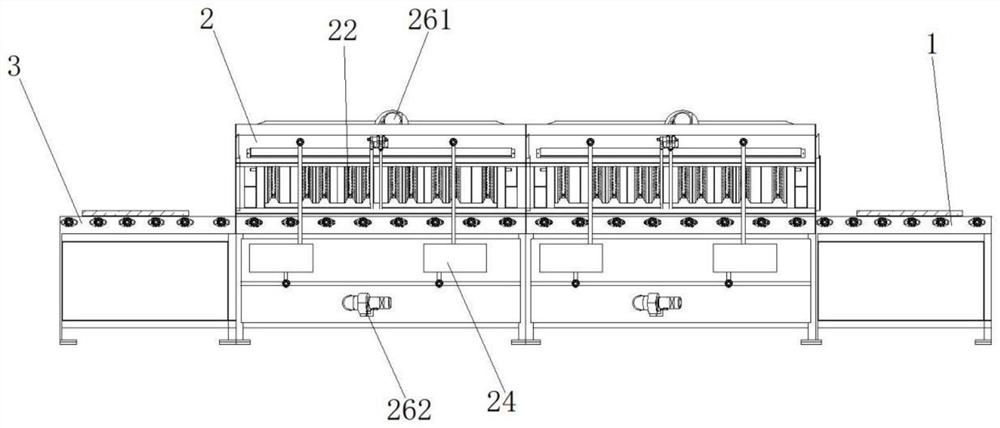

[0038] In a further embodiment of the present invention, several transmission stations all include: a transmission module, a motor and a transmission assembly, the transmission module is electrically connected to the motor, the motor drives the transmission assembly, and the transmission assembly is connected to the transmission shaft 23 through gear transmission.

[0039] In a further embodiment of the present invention, two traction devices 25 respectively pass through the first through hole and the second through hole, two transmission shafts 23 pass through the first through hole, and the other two transmission shafts 23 pass through the second through hole.

[0040] In a further embodiment of the present invention, both traction devices 25 include: several traction wires and several baffle plates, the two ends of each traction wire are respectively connected to two transmission shafts 23, each traction wire is connected to a baffle plate, and the baffle plate is operable B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com