Shadowless glue coating process and system

A coating process and technology of shadowless glue, which is applied in the field of shadowless glue coating technology and systems, can solve the problems of substrate deformation and low heat resistance, and achieve the effect of simple construction and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

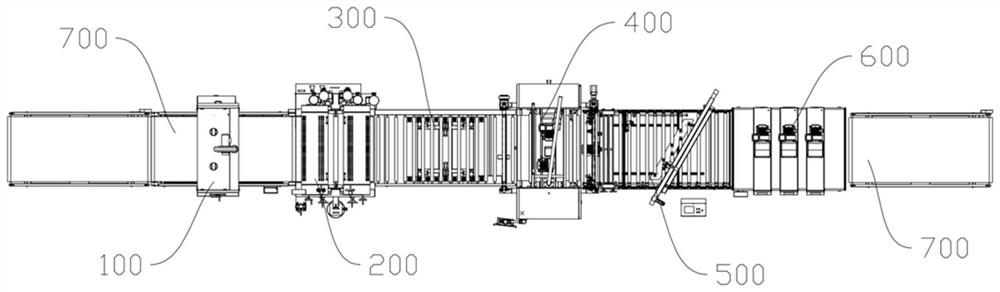

[0027] refer to figure 1 , a shadowless glue coating system, including a conveyor belt 700, a dust remover 100, a double-roller coater 200, a positioning conveyor, a roller press 400, a bevel cutter 500 and a UV drying machine are arranged in sequence along the workpiece conveying direction Machine 600, the material of the pressure roller of roller press 400 is the rubber of hardness 55 °, is provided with the UV lamp that is used for preliminary curing on the roller press 400, and the UV lamp of the present embodiment is an electrodeless mercury lamp, and is provided with on the roller press 400 The fabric unwinding device, the positioning conveyor in this embodiment is the centering machine 300.

[0028] Adopt the shadowless glue coating system of the present embodiment to carry out the shadowless glue coating process, comprising the following steps:

[0029] S1: The conveyor belt 700 carries the plate through the dust removal machine 100, and the dust removal machine 100 p...

Embodiment 2

[0034] refer to figure 1 , a shadowless glue coating system, including a conveyor belt 700, a dust remover 100, a double-roller coater 200, a positioning conveyor, a roller press 400, a bevel cutter 500 and a UV drying machine are arranged in sequence along the workpiece conveying direction Machine 600, the pressure roller material of roller press 400 is the rubber of hardness 60 °, is provided with the UV lamp that is used for initial curing on the roller press 400, and the UV lamp of present embodiment is LED lamp, is provided with fabric on the roller press 400 As for the unwinding device, the positioning conveyor in this embodiment is a centering machine 300 .

[0035] Adopt the shadowless glue coating system of the present embodiment to carry out the shadowless glue coating process, comprising the following steps:

[0036] S1: Use a dust removal machine 100 to remove dust from the surface of the board;

[0037] S2: Use double roll coater 200 to apply shadowless glue to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com