Multi-curing adhesive and preparation method thereof

A multiple curing and adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of high complexity, low use efficiency, monotonous curing method of a single adhesive, etc. , to reduce complexity and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

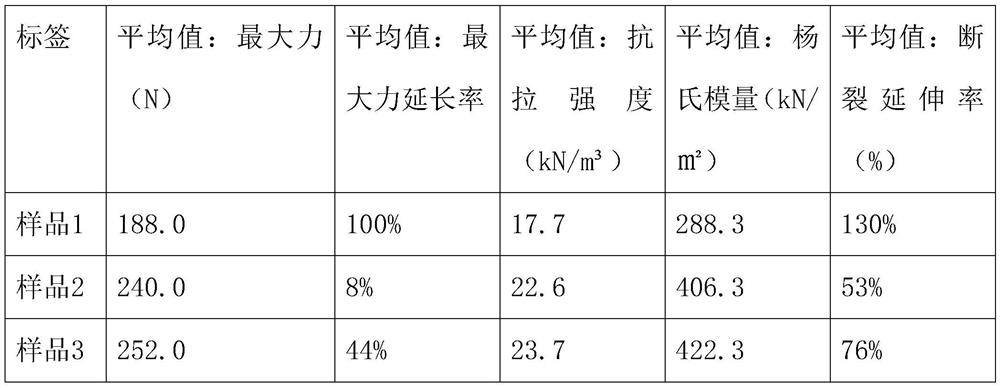

Embodiment 1

[0032] The formula used includes: 23% of acrylic oligomer, 15% of polyurethane oligomer, 15% of isobornyl acrylate, 15% of acrylic monomer, 2.5% of carbon nanotube, 0.5% of graphene, 4-(1-oxo- 2-propenyl)morpholine 10%, (2,4,6-trimethylbenzoyl)diphenylphosphine oxide 2.5%, phenylbis(2,4,6-trimethylbenzoyl)oxidation Phosphine 2.5%, (2-ethylhexanoic acid) tert-butyl peroxide 1.3%, p-hydroxyanisole 0.2%, (methoxycarbonylaminomethyl) trimethoxysilane 2.5%, organic fluorescent toner 2%, 3% of polyethylene wax, 2% of nano-alumina powder, 2% of nano-titanium oxide powder, and 2% of nano-silicon dioxide, and sample 1 was produced.

Embodiment 2

[0034] The formula used includes: 21% acrylic oligomer, 19% polyurethane oligomer, 13% isobornyl acrylate, 15% acrylic monomer, 2.5% carbon nanotube, 0.5% graphene, 4-(1-oxo- 2-propenyl)morpholine 10%, (2,4,6-trimethylbenzoyl)diphenylphosphine oxide 2.5%, phenylbis(2,4,6-trimethylbenzoyl)oxidation Phosphine 2.5%, (2-ethylhexanoic acid) tert-butyl peroxide 1.3%, p-hydroxyanisole 0.2%, (methoxycarbonylaminomethyl) trimethoxysilane 2.5%, organic fluorescent toner 2%, 3% of polyethylene wax, 2% of nano-alumina powder, 2% of nano-titanium oxide powder, and 2% of nano-silicon dioxide, and sample 2 was produced.

Embodiment 3

[0036]The formula used includes: 22% acrylic oligomer, 11% polyurethane oligomer, 19% isobornyl acrylate, 17% acrylic monomer, 2.5% carbon nanotube, 0.5% graphene, 4-(1-oxo- 2-propenyl)morpholine 9%, (2,4,6-trimethylbenzoyl)diphenylphosphine oxide 2.5%, phenylbis(2,4,6-trimethylbenzoyl)oxidation Phosphine 2.5%, (2-ethylhexanoic acid) tert-butyl peroxide 1.3%, p-hydroxyanisole 0.2%, (methoxycarbonylaminomethyl) trimethoxysilane 2.5%, organic fluorescent toner 2%, 3% of polyethylene wax, 2% of nano-alumina powder, 2% of nano-titanium oxide powder, and 2% of nano-silicon dioxide, to produce sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com