Diamond wire cutting equipment for water treatment membrane element

A diamond wire cutting and water treatment membrane technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding workpiece support, etc., can solve the problem of high cost of milling cutter cutting equipment, affecting the performance of membrane elements, and cutting debris Reduce cutting waste, high cutting efficiency, and less cutting debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

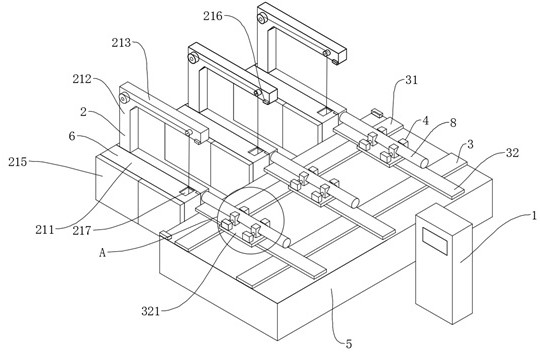

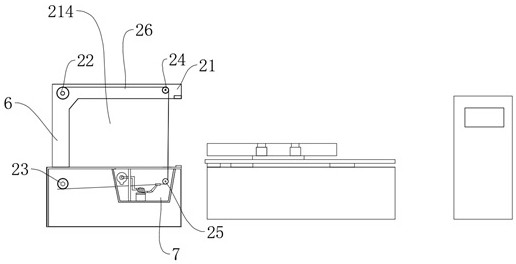

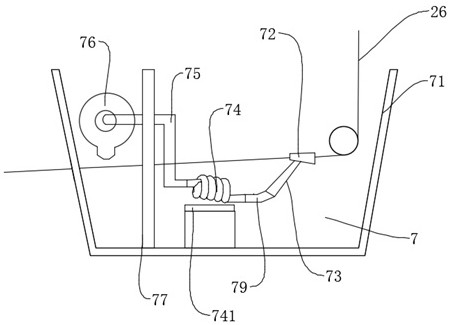

[0048]A water treatment membrane element diamond wire cutting equipment, including a man-machine interaction system 1, a diamond wire retraction system 2, a slide rail moving system 3, a membrane element fixing mechanism 4, a fixed bed 5, a frame 6, and an air-cooled chip removal mechanism 7. The frame 6 is located on the left side of the fixed bed 5, the slide rail moving system 3 is set on the fixed bed 5, and the membrane element fixing mechanism 4 is installed on the slide rail moving system 3 , the diamond wire retracting system 2 is arranged on the frame 6, the air-cooled debris removal mechanism 7 is arranged in the frame 6, and the diamond wire retracting system 2 includes a frame 21, a Wire wheel 22, take-up wheel 23, guide wheel 24, tension wheel 25, diamond wire 26, described frame 21 comprises workbench 211, side plate 212 vertically with described workbench and is connected with described side plate 212 The top plate 213 of the workbench 211, the side plate 212 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com