Speek/modified bentonite composite ion exchange membrane and its preparation method

A technology of composite ions and bentonite, applied in the field of ion exchange membranes, can solve the problems of poor ion selectivity, poor single cell performance, and low ion conductivity, and achieve good battery performance, improved water absorption, and simple modification methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of SPEEK / modified bentonite composite ion exchange membrane comprises the following steps:

[0041] Step 1, prepare modified bentonite particles:

[0042] Step 11, dry purification: crushing, grinding and sieving the bentonite to obtain sieved bentonite powder. The number of sieve meshes is 100 mesh to 400 mesh.

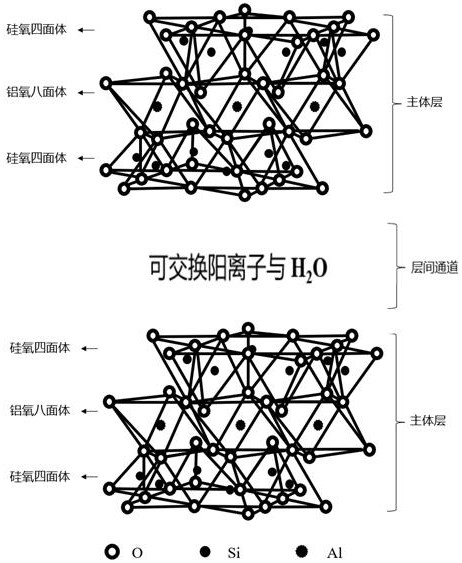

[0043] Bentonite is a non-metallic mineral, the main mineral composition is montmorillonite Al 2 [Si 4 o 10 ](OH) 2 · n h 2 O, bentonite in this application is derived from common commercial products, and its main mineral composition structure is as follows: figure 1 shown.

[0044] Step 12, modification treatment: place the sieved bentonite powder in the modification solution with a concentration of 2mol / L~3mol / L at a mass volume ratio of 1g:(3mL~5mL), and use 200r / min~2000r / min Stir at a stirring rate of min for 24h~48h to obtain a modified bentonite suspension.

[0045] The purity of the sieved bentonite powder is 85%~98%. ...

Embodiment 1

[0068] The preparation method of SPEEK / modified bentonite composite ion exchange membrane comprises the following steps:

[0069] (1) Preparation of modified bentonite particles:

[0070] (1.1) Dry purification: crush the bentonite, grind it, and pass through a 100-mesh sieve to obtain sieved bentonite powder with a purity of 95%.

[0071] (1.2) Modification treatment: put 100g of sieved bentonite powder in 300mL of H2O with a concentration of 2mol / L 2 SO 4 In the aqueous solution, stir at a stirring rate of 200 r / min for 24 hours to obtain a modified bentonite suspension.

[0072] The modification degree of bentonite in the modified bentonite suspension is 50%.

[0073] (1.3) High-speed centrifugal purification: centrifuge the modified bentonite suspension obtained in (1.2) for 30 min at a speed of 1000 r / min, and centrifuge twice to obtain a modified bentonite paste.

[0074] (1.4) Roasting modification: transfer the modified bentonite paste obtained in (1.3) to an oven, a...

Embodiment 2

[0086] The preparation method of SPEEK / modified bentonite composite ion exchange membrane comprises the following steps:

[0087] (1) Preparation of modified bentonite particles:

[0088] (1.1) Dry purification: crush the bentonite, grind it, and pass through a 400-mesh sieve to obtain sieved bentonite powder with a purity of 95%.

[0089] (1.2) Modification treatment: Put 100 g of sieved bentonite powder into 500 mL of 3 mol / L NaCl aqueous solution, and stir at a stirring rate of 2000 r / min for 24 hours to obtain a modified bentonite suspension.

[0090] The modification degree of bentonite in the modified bentonite suspension is 40%.

[0091] (1.3) High-speed centrifugal purification: the modified bentonite suspension was centrifuged at a speed of 20000r / min for 2min, and centrifuged 10 times to obtain a modified bentonite paste.

[0092] (1.4) Roasting modification: transfer the modified bentonite paste to a muffle furnace, and roast it at 120°C for 12 hours. The resultin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com