Composition and device for treating acidic iron ore waste liquid and preparation method of composition

A composition and iron ore technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, water treatment parameter control, etc., can solve the problems of gas poisoning, water pollution, frequent equipment maintenance, etc., to improve pH value, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

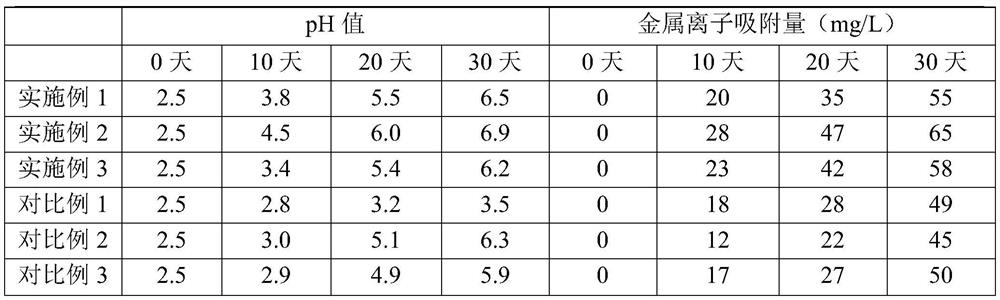

Examples

Embodiment 1

[0039] A device for treating acidic iron ore waste liquid, the device is a plate-shaped filter material, and the device is prepared from the following composition, and the component formula of the composition is: low-alkali cement 40%, polyethyleneimine 5%, immobilized microbial agent 5%, foaming agent 0.1%, clay 0.1%, activated carbon 1%, plant fiber 0.5%, and the balance is water.

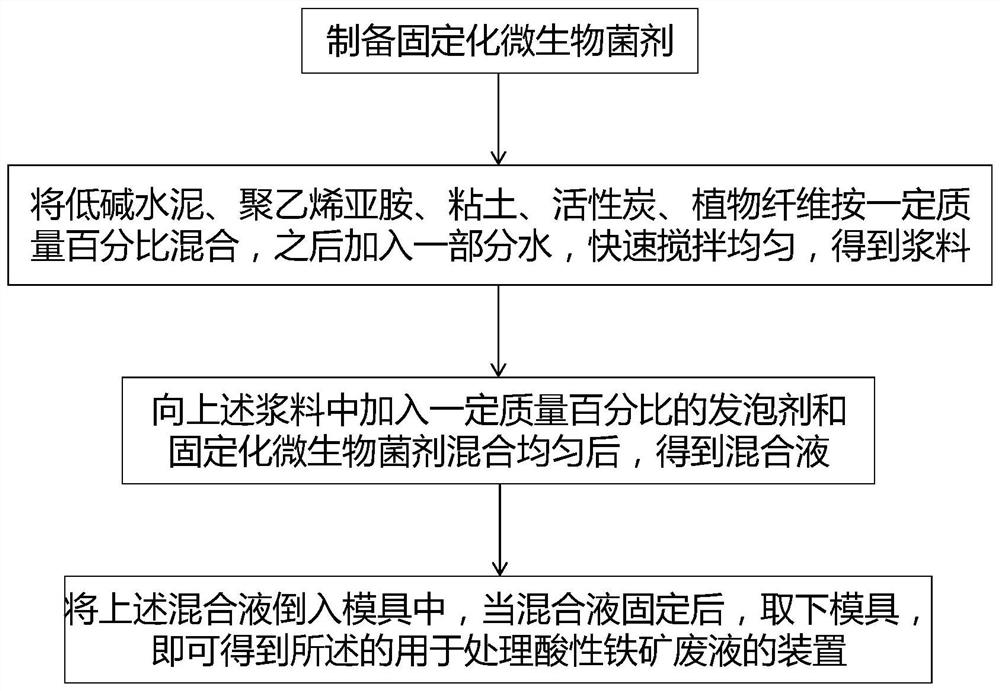

[0040] The preparation method of the device for the treatment of acidic iron ore waste liquid, the device is a plate-shaped filter material, specifically comprising the steps of:

[0041] S1, preparing immobilized microbial bacterial agent;

[0042] S11, the activation of microbial bacterial agent: inoculate bacillus in LB culture medium, shake flask to expand culture, stand-by;

[0043] S12. Mixing of microbial bacterial liquid with sodium alginate solution: take a certain amount of sodium alginate and dissolve it in water, mix the sodium alginate solution with the microbial bacterial liquid ob...

Embodiment 2

[0049] A device for treating acidic iron ore waste liquid, the device is a plate-shaped filter material, and the device is prepared from the following composition, and the component formula of the composition is: low-alkali cement 45%, polyethyleneimine 10%, immobilized microbial agent 7%, foaming agent 0.3%, clay 0.5%, activated carbon 1.5%, plant fiber 1.2%, and the balance is water.

[0050] The preparation method of the device for the treatment of acidic iron ore waste liquid, the device is a plate-shaped filter material, specifically comprising the steps of:

[0051] S1, preparing immobilized microbial bacterial agent;

[0052] S11. Activation of microbial bacterial agents: inoculate Pseudomonas in LB medium, expand culture in shake flasks, and set aside;

[0053] S12. Mixing of microbial liquid with sodium alginate solution: take a certain amount of sodium alginate and dissolve it in water, mix the sodium alginate solution with the microbial liquid obtained in step S1, ...

Embodiment 3

[0059] A device for treating acidic iron ore waste liquid, the device is a plate-shaped filter material, and the device is prepared from the following composition, and the component formula of the composition is: low-alkali cement 50%, polyethyleneimine 15%, immobilized microbial agent 10%, foaming agent 0.5%, clay 1%, activated carbon 2%, plant fiber 2%, and the balance is water.

[0060] The preparation method of the device for the treatment of acidic iron ore waste liquid, the device is a plate-shaped filter material, specifically comprising the steps of:

[0061] S1, preparing immobilized microbial bacterial agent;

[0062] S11. Activation of microbial bacterial agents: inoculate Pseudomonas and Alcaligenes in LB medium, expand culture in shake flasks, and set aside;

[0063] S12. Mixing of microbial liquid with sodium alginate solution: take a certain amount of sodium alginate and dissolve it in water, mix the sodium alginate solution with the microbial liquid obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com