Copper-based powder metallurgy friction material with high-stability friction coefficient and preparation method

A technology of powder metallurgy and friction coefficient, which is applied in the direction of friction linings, metal processing equipment, mechanical equipment, etc., can solve the problems that it is impossible to explain whether the copper-based material meets the technical requirements of the product, and the copper-based material has not been tested and verified, and the amount of deformation can be achieved. Small size, good wear resistance, and low expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

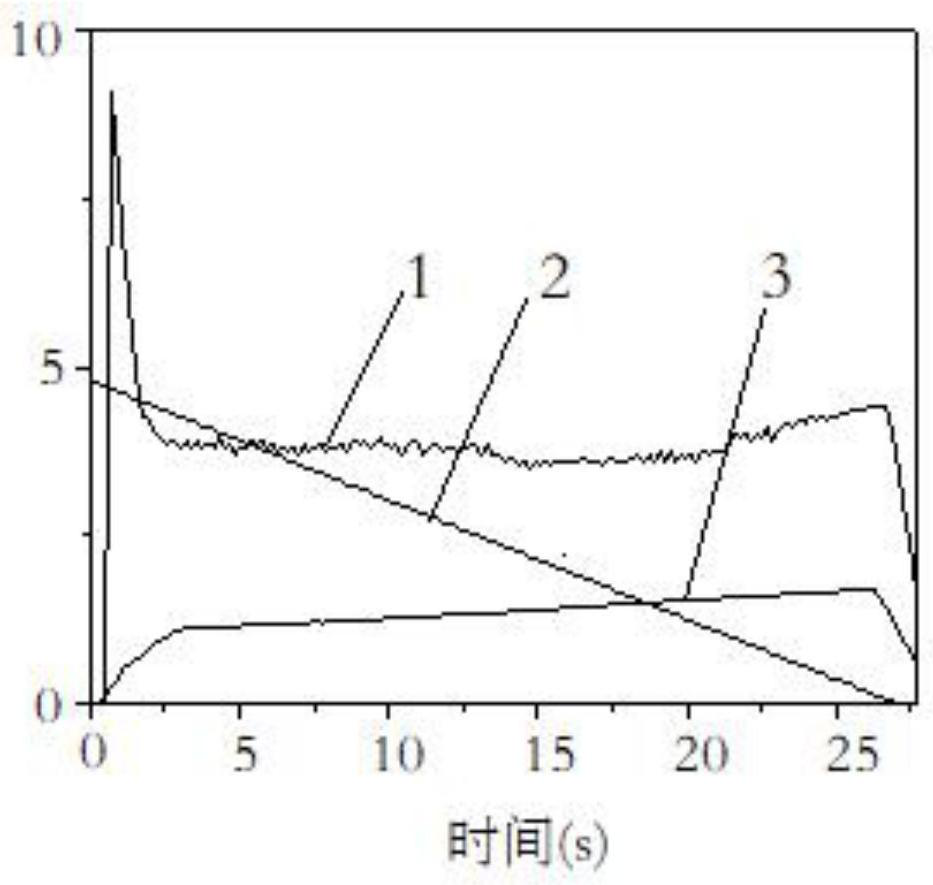

Image

Examples

Embodiment Construction

[0046] The invention is a copper-based powder metallurgy friction material with high stable friction coefficient, which is composed of 48-52% electrolytic copper powder, 18-24% reduced iron powder, 12-16% graphite, 3-6% ferrochrome alloy and aluminum oxide 2-4%, molybdenum powder 2-4%, precipitated barium sulfate 2-5% and polyvinyl alcohol powder 3-6%, and the stated percentages are mass percentages.

[0047] The present invention specifically illustrates its technical scheme through 4 embodiments. The components of each embodiment are shown in Table 1:

[0048] The components of each implementation example proposed by the present invention are shown in Table 1, wherein the content of each component is in mass percent (%).

[0049] Table 1

[0050]

[0051] The content of Cu in the electrolytic copper powder is ≥99.8%, and the implementation standard is GB / T5246-2007.

[0052] The content of Fe in the reduced iron powder is more than or equal to 98.5%, and the implementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com