Aluminum foil product production forming stamping die

A technology for stamping dies and products, applied in forming tools, manufacturing tools, cleaning methods and utensils, etc., can solve the problems of unqualified aluminum foil quality, pre-stamping position change, offset and other problems, so as to reduce the quality of stamping and reduce the possibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

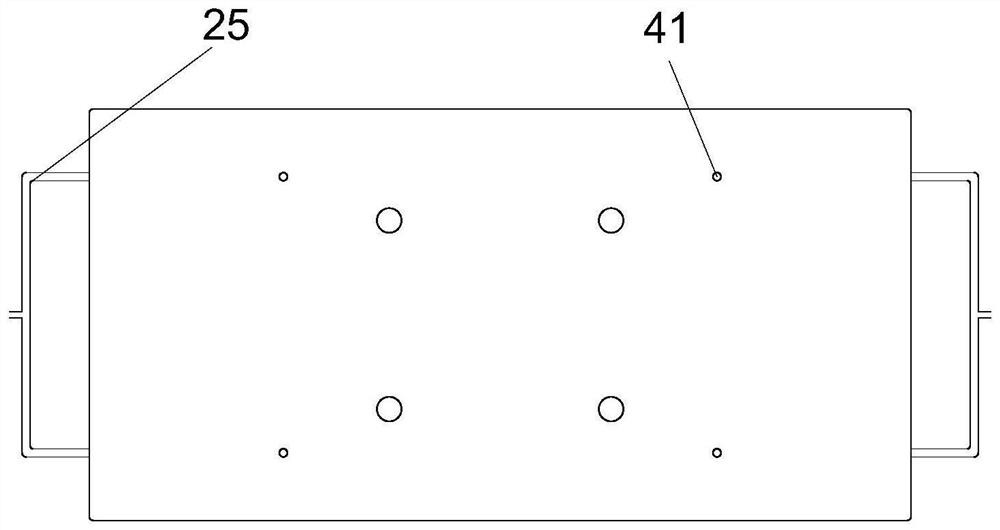

[0025] As an embodiment of the present invention, the positions of the positioning blocks 32 and the air holes 41 are dislocated.

[0026] During the stamping process, the position dislocation distribution of the positioning block 32 and the air hole 41 can make the force distribution on the aluminum foil more uniform, improve the positioning effect of the aluminum foil, reduce the occurrence of quality defects on the surface of the aluminum foil due to concentrated force, and further improve the quality of the aluminum foil. Stamping quality and efficiency.

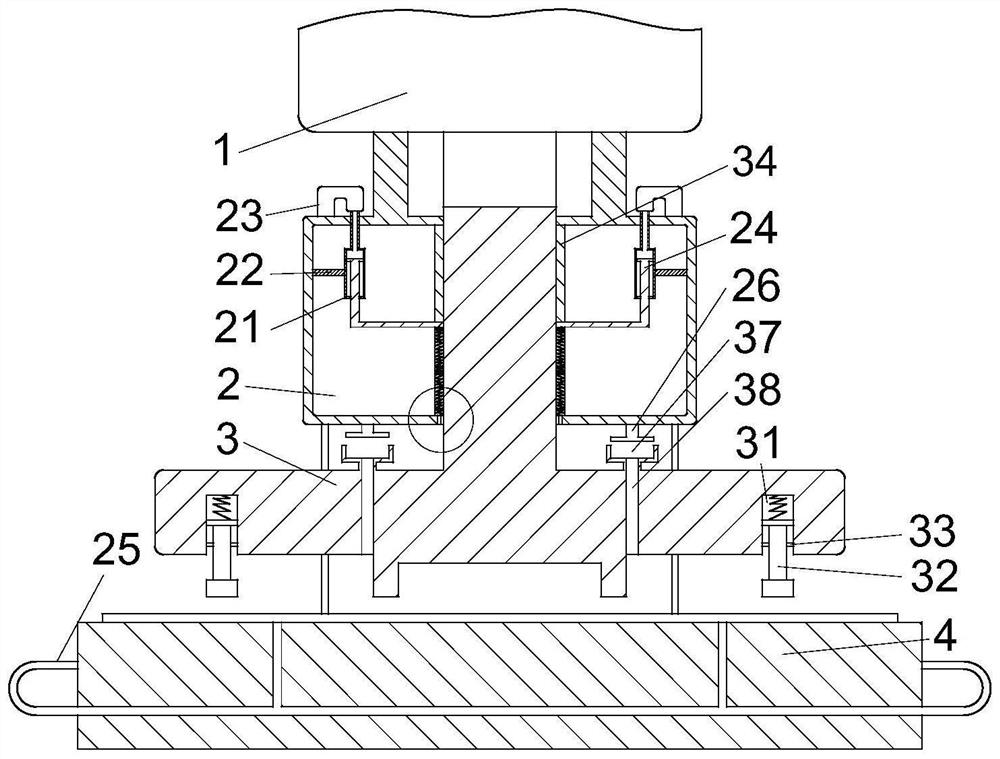

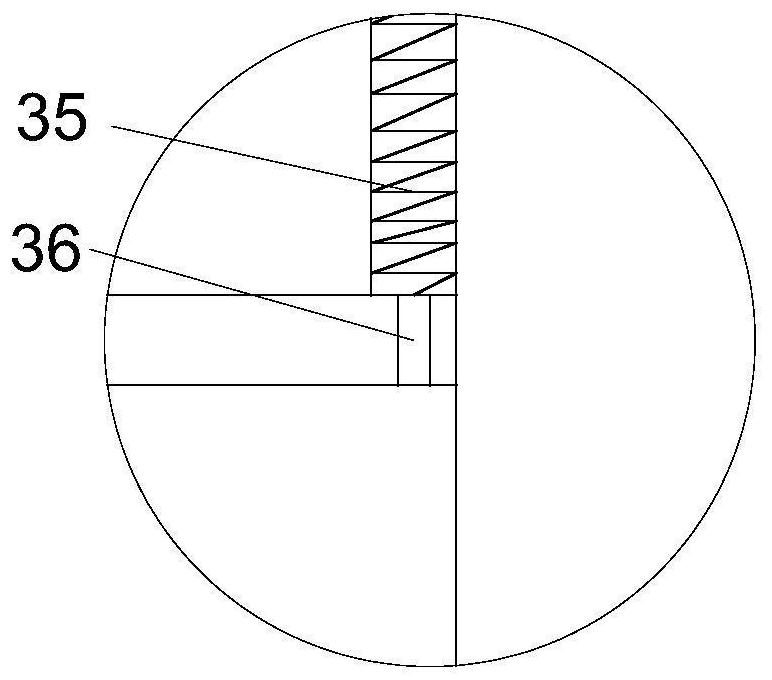

[0027] As an embodiment of the present invention, the box body 2 is provided with a chute 34, and the upper mold base 3 drives the piston rod 24 to slide up and down in the chute 34 when it moves up and down; the chute 34 is provided with corrugated Pipe 35; one end of the bellows 35 is connected to the piston rod 24, and the other end is connected to the bottom of the chute 34; the bottom of the chute 34 has a hole 36 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com