Preparation method of novel ternary positive electrode material, positive electrode material, lithium battery prepared from positive electrode material and application of lithium battery

A cathode material, lithium battery technology, applied in the direction of lithium storage battery, positive electrode, secondary battery, etc., can solve the problems of complex process, unsuitable for industrial production, high cost, etc., to prevent dissolution, improve electronic conductivity and lithium ion Ion transport ability, sufficient contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a novel ternary cathode material, comprising the following steps:

[0030] Step a) mixing nickel-cobalt-manganese precursor, lithium source, and dopant M oxide, and sintering at 500-1000°C to obtain the positive electrode material;

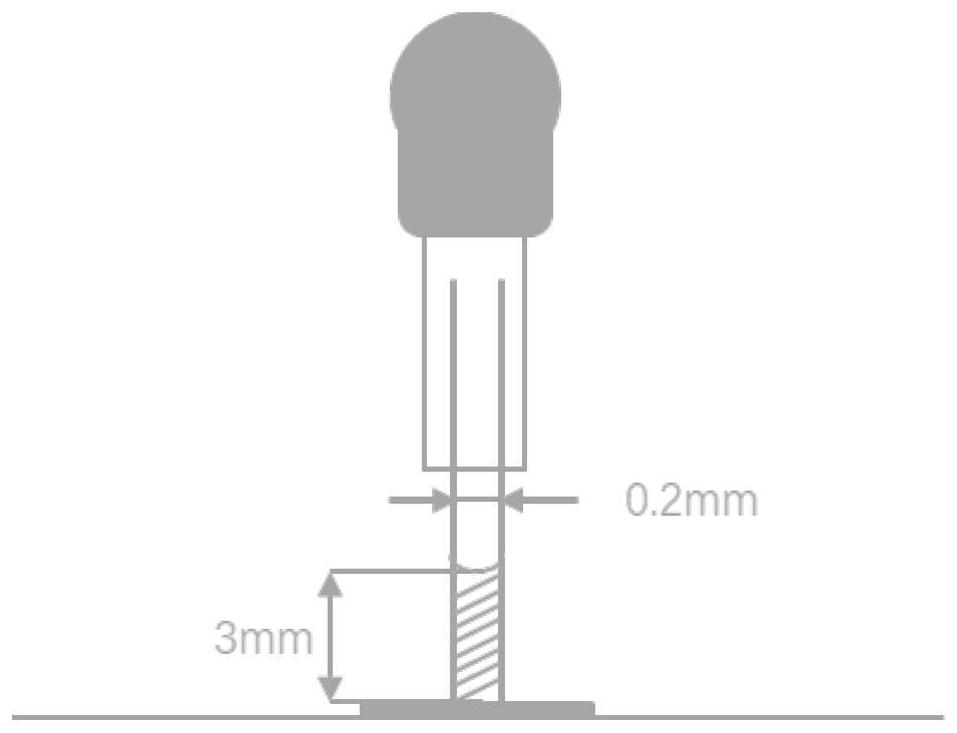

[0031] Step b) Combine the positive electrode material with oxidized carbon black, N,N-dimethylamide (DMF) and high melting point metal carbonyl compound N(CO) t Mix to obtain a suspension, and ultrasonically homogenize it; then heat and stir in an oil bath, then filter and dry to obtain a doped carbon-coated ternary cathode material;

[0032] Wherein, the median particle size D50 of the nickel-cobalt-manganese precursor in step a) is 4-8 μm, for example including but not limited to 4 μm, 4.5 μm, 5 μm, 5.5 μm, 6 μm, 6.5 μm, 7 μm, 7.5 μm, 8 μm, so The nickel-cobalt-manganese precursor is, for example, Ni a co b mn c (OH) 2 , where, 0.6≤a≤0.9, 0.05≤b≤0.2, 0.05≤c≤0.3. The nickel-cobalt-manganese precursor may be a...

Embodiment 1

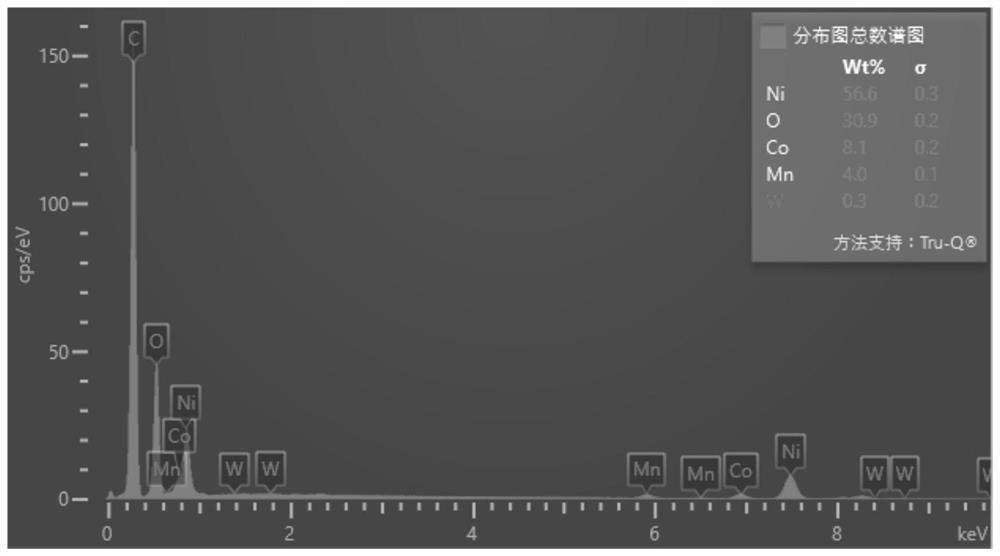

[0049] S1: Use Ni with a particle size D50 of 8 μm 0.83 co 0.12 mn 0.05 (OH) 2 Precursor and LiOH·H 2 O and 1500ppm additive ZrO 2 Mixed, and heated to 800°C with oxygen in the muffle furnace, sintered at constant temperature for 10h, and then cooled to room temperature to obtain LiNi 0.83 co 0.12 mn 0.05 Zr 0.01 o 2 .

[0050] S2: 30g of LiNi 0.83 co 0.12 mn 0.05 Zr 0.01 o 2 , 1.07g of W(CO) 6 And 1.2g oxidized carbon black is dissolved in the DMF of 28.8g (30.48mL), wherein anode material and total solution mass ratio 50wt%, oxidized carbon black and total solution mass ratio 2wt%, W (CO) 6 The concentration is 0.1mol / L. Ultrasonic treatment was performed for 1 hour at an ultrasonic frequency of 200 Hz to obtain a mixed liquid.

[0051] S3: Transfer the mixed liquid to a pressure-resistant bottle, heat to 200° C. in an oil bath, and stir magnetically for 10 h. Cool to room temperature; then filter and wash the solution, dry it in a vacuum oven at 100°C for...

Embodiment 2

[0053] S1: Use Ni with a particle size D50 of 5 μm 0.6 co 0.1 mn 0.3 (OH) 2 Precursor and LiOH·H 2 O and 1200ppm additive Al 2 o 3 Mixed, heated to 880°C by feeding oxygen into the muffle furnace, sintered at constant temperature for 10h, and then cooled to room temperature to obtain LiNi 0.6 co 0.1 mn 0.3 Al 0.01 o 2 .

[0054] S2: 30g of LiNi 0.6 co 0.1 mn 0.3 Al 0.01 o 2 , 1.61g of W(CO) 6 And 1.2g oxidized carbon black is dissolved in the DMF of 28.8g (30.48mL), wherein anode material and total solution mass ratio 50wt%, oxidized carbon black and total solution mass ratio 2wt%, W (CO) 6 The concentration is 0.15mol / L. Ultrasonic treatment was performed for 3 hours at an ultrasonic frequency of 300 Hz to obtain a mixed liquid.

[0055] S3: Transfer the mixed liquid to a pressure-resistant bottle, heat to 180° C. in an oil bath, and stir magnetically for 10 h. Cool to room temperature. After the solution was filtered and cleaned, it was dried in a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com