Method for etching pattern by hard mask and preparation method of refrigeration infrared detector

A technology of hard mask and hard mask layer, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc. It can solve the problems of reducing the yield and performance of cooled infrared detectors, undercutting, and affecting the normal progress of the process, etc. , to achieve the effect of reducing undercutting, improving yield, and reducing filling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the current cooling infrared detector comprises the following steps:

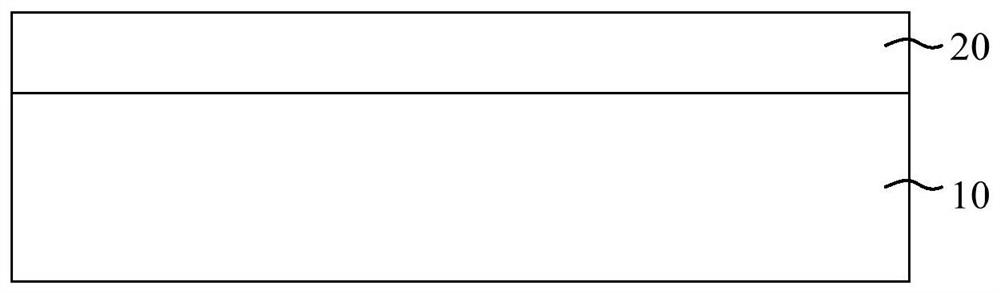

[0034] like Figure 1a As shown, step S11: a superlattice substrate 10 is provided, and SiO is formed on the superlattice substrate 10 2 hard mask layer 20 .

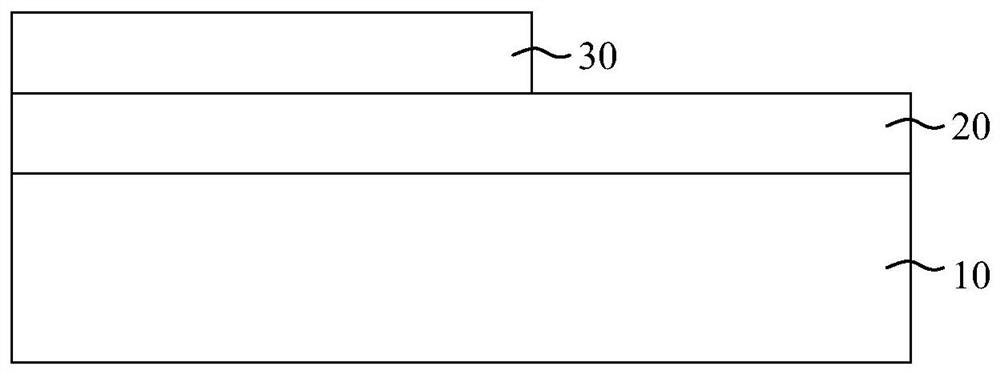

[0035] like Figure 1b As shown, step S12: forming a patterned photoresist layer 30 on the hard mask layer 20, the patterned photoresist layer 30 has a pattern, and the pattern is used to form a mesa.

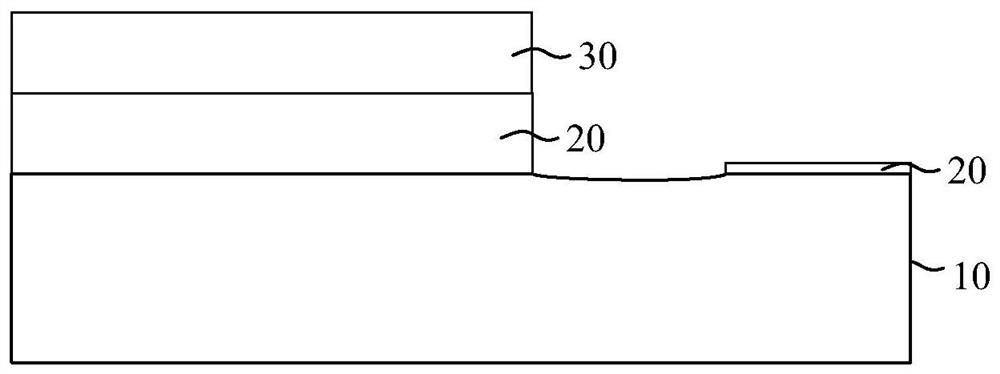

[0036] like Figure 1c As shown, step S13: using the patterned photoresist layer 30 as a mask to etch the SiO at one time 2 hard mask layer 20 to transfer the pattern to the SiO 2 hard mask layer 20 and expose the superlattice substrate 10 . At this time, due to pattern effect, in the SiO 2 There will be SiO in the etched area of the hard mask layer 20 2 Material remains, resulting in undercutting. In addition, the SiO after etching 2 The hard mask layer 20 is prone to breakage.

[0037] According to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com