Tantalum surface calcium-doped sodium tantalate bioactive layer and preparation method thereof

A bioactive, sodium tantalate technology, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problem of no introduction of functional element Ca, poor biological activity of metal tantalum, weak ability to form new bones, etc. problems, to achieve the effect of promoting bone apatite induction, improving biocompatibility, and promoting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. A method for preparing a tantalum surface calcium-doped sodium tantalate bioactive layer, the steps are as follows:

[0035] Step 1: Put the tantalum sheet and NaOH hydrothermal solution into the hydrothermal reactor for hydrothermal treatment, that is, a uniform NaTaO is formed on the surface of the tantalum 3 film layer; wherein the hydrothermal reaction is a chemical reaction as follows:

[0036] 2Ta+10NaOH=Ta 2 o 5 +5Na 2 O+5H 2 ↑

[0037] Ta 2 o 5 +Na 2 O=2NaTaO 3

[0038] Na 2 O+H 2 O=2NaOH

[0039] Step 2: Cover with NaTaO 3 The tantalum sheet of the film layer is placed in CaCl 2 Molten salt treatment is carried out in the powder, that is, doped Ca is formed on the surface of the tantalum 2+ NaTaO 3 film layer.

[0040] The concentration of NaOH solution in step one is 2mol / L.

[0041] In step 1, when the hydrothermal solution is injected into the hydrothermal reaction vessel, the filling degree of the solution is 30%-40%, and then the tanta...

Embodiment 1

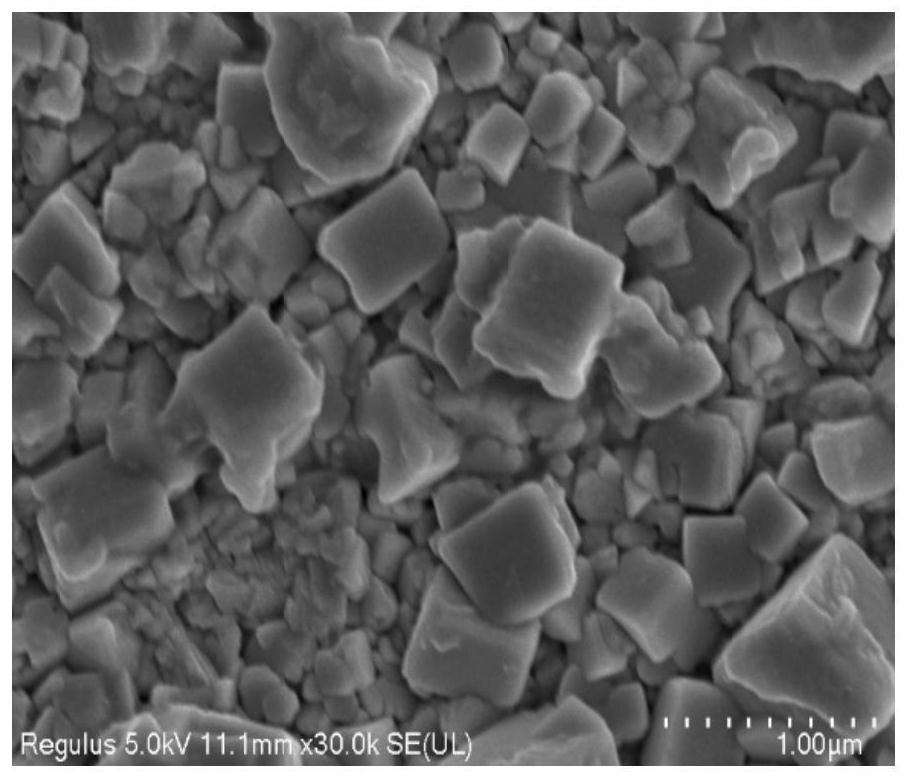

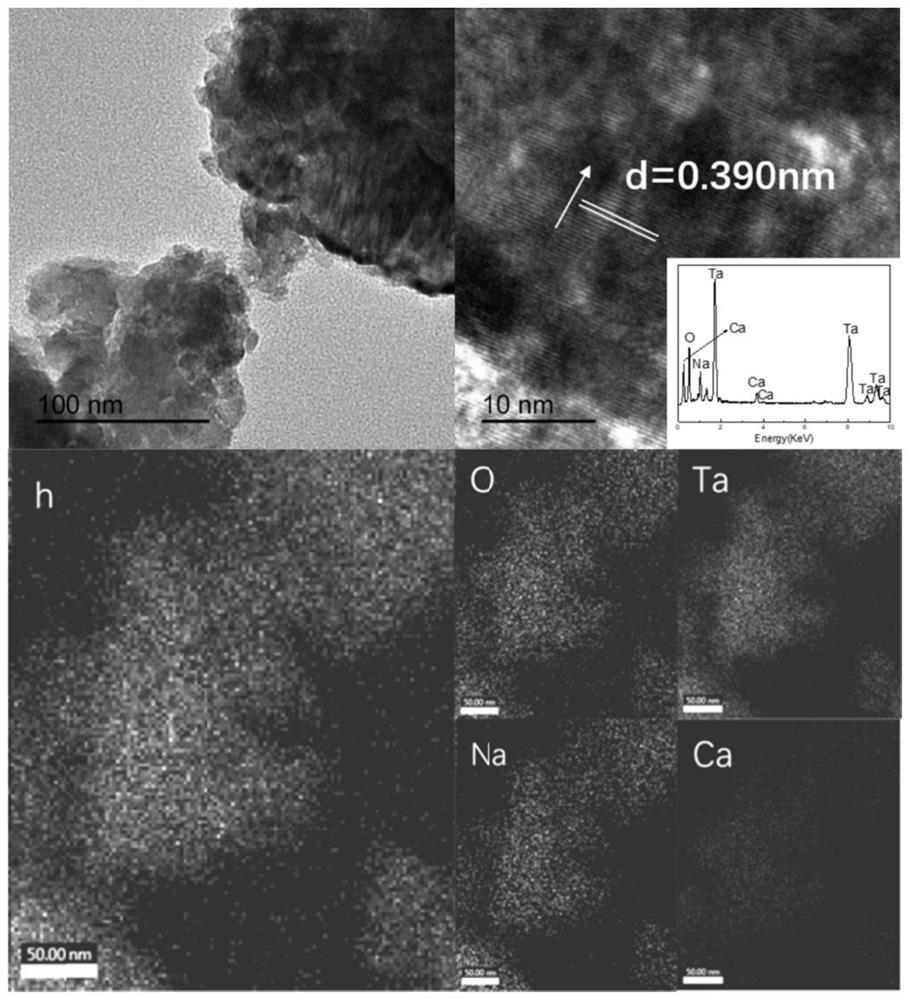

[0057] Prepare a NaOH hydrothermal solution with a molar concentration of 2mol / L, inject it into a hydrothermal reaction vessel, and fill the solution with a degree of 30%, soak the tantalum sample in the solution, and treat it hydrothermally at 220°C for 24 hours, namely The sodium tantalate film can be obtained on the surface of the tantalum base, the microstructure of the film is cube-shaped, and the diameter of the cube is about 150 nanometers to 1 micron;

[0058] The treated tantalum sheet covered with sodium tantalate film was buried in anhydrous calcium chloride powder and put into the crucible together. The powder filling degree was 90%. The heating time from room temperature to 450°C was 90 minutes. The holding time is 3 hours, and the calcium-doped sodium tantalate structural coating can be obtained on the tantalum surface after cooling in the furnace. The microstructure of the coating is still cubic, the water contact angle is 66.7°, the roughness Ra value is about...

Embodiment 2

[0060] Prepare a NaOH hydrothermal solution with a molar concentration of 2mol / L, inject it into a hydrothermal reaction vessel, and fill the solution with a degree of 30%, soak the tantalum sample in the solution, and treat it hydrothermally at 220°C for 24 hours, namely The sodium tantalate film can be obtained on the surface of the tantalum base, the microstructure of the film is cube-shaped, and the diameter of the cube is about 150 nanometers to 1 micron;

[0061] The treated tantalum sheet covered with sodium tantalate film was buried in anhydrous calcium chloride powder and put into the crucible together. The powder filling degree was 90%. The heating time from room temperature to 550°C was 90 minutes. The holding time is 3 hours, and the calcium-doped sodium tantalate structural coating can be obtained on the tantalum surface after cooling in the furnace. The microstructure of the coating is still cubic, the water contact angle is 13.9°, the roughness Ra value is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com