Low-temperature-resistant neutral silicone sealant and preparation method thereof

A silicone sealant, low temperature resistant technology, applied in the field of silicone adhesive, can solve the problems of carcinogenic risk and inapplicability, and achieve the effect of ensuring bonding strength, improving environmental protection, and improving deep curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

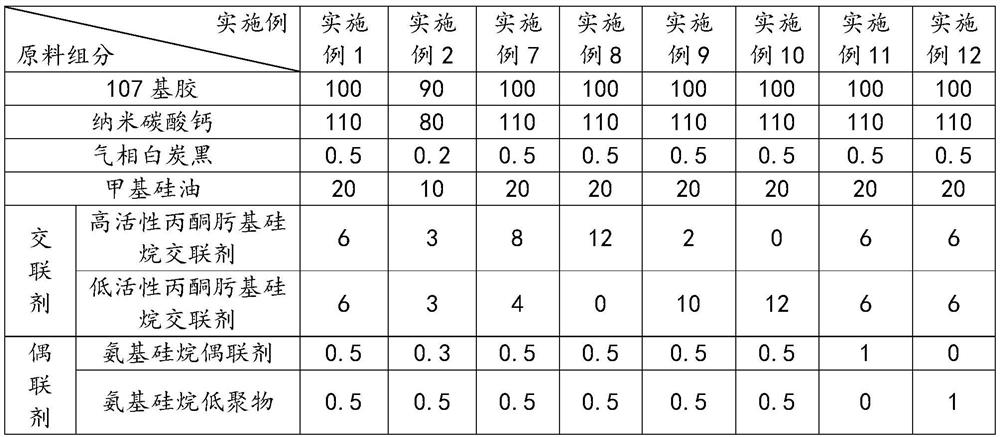

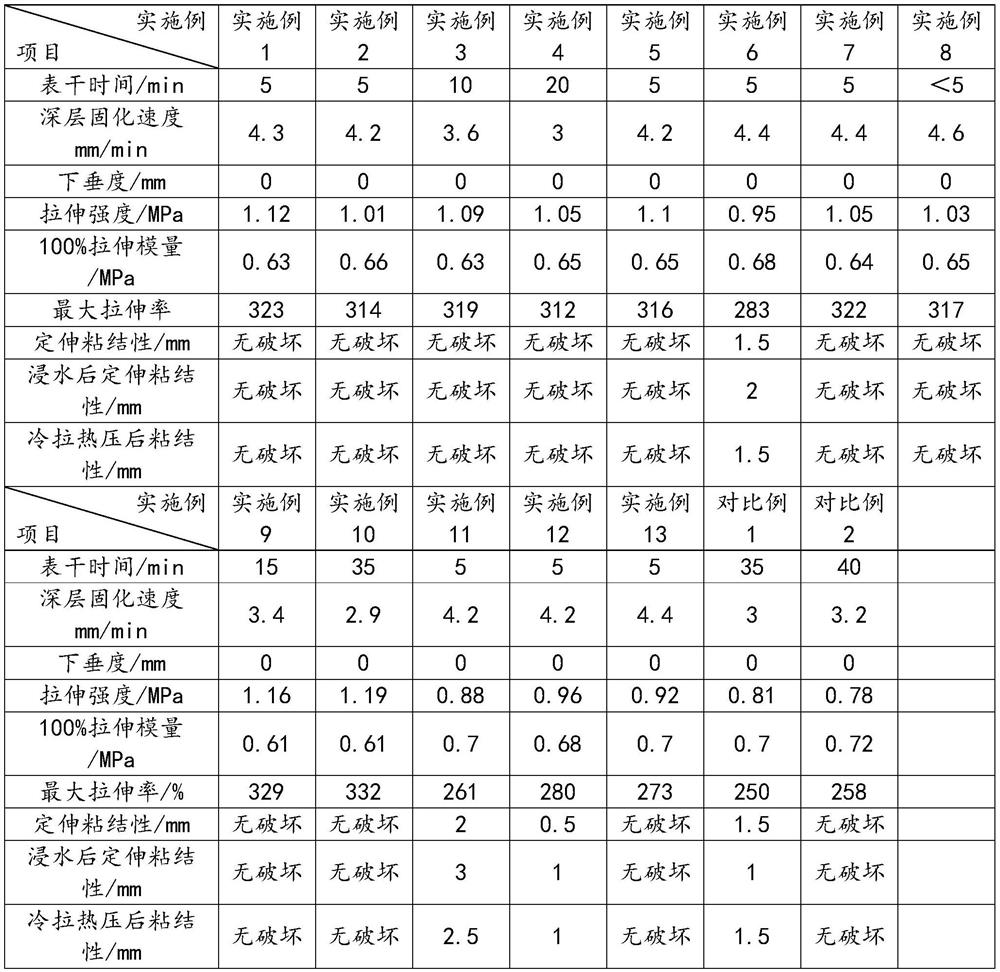

Examples

preparation example 1

[0043] Preparation Example 1, an aminosilane oligomer, was prepared according to the following steps:

[0044] S101: In a 3000ml three-necked flask, add 1500g aminopropyltrimethoxysilane and ammonia 250g methanol, then install a reflux condenser, a thermometer and a constant pressure dropping funnel on the three-necked flask, and make the three-necked flask under stirring conditions The temperature of the mixture is raised to 50°C, and then a mixed solution of 50g of water and 150g of methanol is dropped through a constant pressure dropping funnel to promote the full hydrolysis of the aminosilane coupling agent to obtain a hydrolyzate;

[0045] S102: Heat the hydrolyzate to 100°C, polymerize for 1.5 hours, and collect methanol by distillation under reduced pressure to obtain a prepolymer, then continue to heat the prepolymer to 130°C, polymerize for 2 hours, and cool down to room temperature to obtain an average degree of polymerization of 6 aminosilane oligomers.

preparation example 2

[0046] Preparation 2, an aminosilane oligomer, was prepared according to the following steps:

[0047] S101: In a 3000ml three-necked flask, add 1500g of aminopropyltriethoxysilane and ammonia 250g methanol, then install a reflux condenser, a thermometer and a constant pressure dropping funnel on the three-necked flask, and make the three-necked flask The temperature of the mixture was raised to 50°C, and then a mixed solution of 30g of water and 170g of methanol was dropped through a constant pressure dropping funnel to promote the full hydrolysis of the aminosilane coupling agent to obtain a hydrolyzed product;

[0048] S102: Heat the hydrolyzate to 100°C, polymerize for 1 hour, and collect methanol by vacuum distillation to obtain a prepolymer, then continue to heat the prepolymer to 120°C, polymerize for 2 hours, and cool it down to room temperature to obtain a compound with an average degree of polymerization of 3. Aminosilane oligomers.

preparation example 3

[0049] Preparation Example 3, an aminosilane oligomer, was prepared according to the following steps:

[0050] S101: In a 3000ml three-necked flask, add 1500g N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane and 300g methanol of ammonia, then install a reflux condenser, a thermometer and a constant pressure dropping funnel on the three-necked flask , under stirring conditions, the temperature of the mixture in the three-necked flask was raised to 50 ° C, and then the mixed solution of 50 g of water and 150 g of methanol was dropped through a constant pressure dropping funnel to promote the sufficient hydrolysis of the aminosilane coupling agent to obtain a hydrolyzed product;

[0051] S102: Heat the hydrolyzate to 100°C, polymerize for 2 hours, and collect methanol by vacuum distillation to obtain a prepolymer, then continue to heat the prepolymer to 130°C, polymerize for 2.5 hours, and cool it down to room temperature to obtain an average degree of polymerization of 9 aminosila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com