Phase-transition-adjustable polymer/laponite nano particle compound thermally induced hydrogel as well as preparation method and application of phase-transition-adjustable polymer/laponite nano particle compound thermally induced hydrogel

A nanoparticle and diatomite technology, which is applied in the field of polymer/lithium diatomite nanoparticle composite thermally induced hydrogel and its preparation, can solve problems such as inability to meet, achieve good biocompatibility, and increase the cell's ability to produce energy. sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

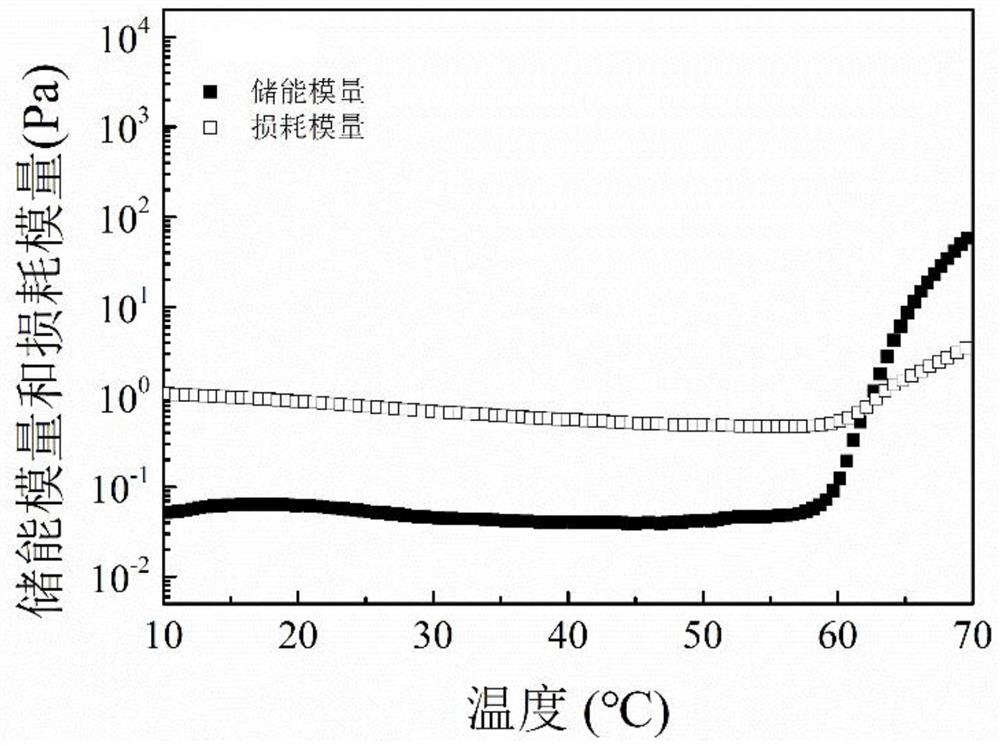

Embodiment 1

[0037] First, 0.500g (0.25mmol) mPEG 2000 -NH 2 Remove water azeotropically with 50 mL of toluene until the remaining solvent volume is 5 mL, seal the system and cool to room temperature. 0.240g (2.09mmol) L-alanine-N-carboxyl anhydride (L-Ala-NCA) and 0.065g (0.34mmol) L-phenylalanine-N-carboxyl anhydride (L-Phe -NCA) monomer was added to 20 mL of CHCl dried over anhydrous magnesium sulfate 3 / DMF (v / v 3:1) mixed solvent, and magnetically stirred at room temperature for 30min. Under an atmosphere of argon, transfer the solution of mixed monomers to dry mPEG 2000 -NH 2 Then, the temperature of the system was raised to 37° C., and the reaction was carried out under magnetic stirring for 3 days under an atmosphere of argon. The system was then cooled to room temperature, and 20 mL of CHCl was added 3 , after the reaction product was completely dissolved, it was added dropwise into glacial ether for precipitation, and the above operation was repeated three times. Finally, t...

Embodiment 2

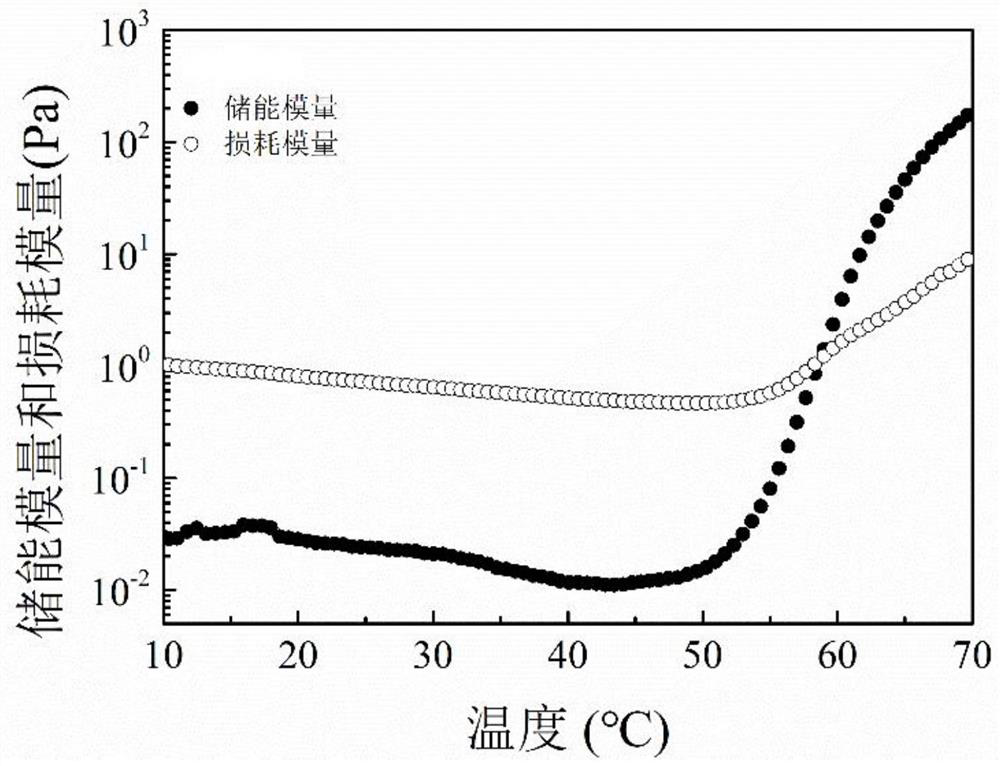

[0039] First, 0.500g (0.10mmol) mPEG 5000 -NH 2 Remove water azeotropically with 50 mL of toluene until the remaining solvent volume is 5 mL, seal the system and cool to room temperature. Add 0.012 g (0.10 mmol) of L-alanine-N-carboxy anhydride (L-Ala-NCA) monomer to 20 mL of CHCl dried over anhydrous magnesium sulfate 3 / DMF (v / v 3:1) mixed solvent, and magnetically stirred at room temperature for 30min. Under an atmosphere of argon, transfer the solution of mixed monomers to dry mPEG 5000 -NH 2 Then, the temperature of the system was raised to 37° C., and the reaction was carried out under magnetic stirring for 3 days under an atmosphere of argon. The system was then cooled to room temperature, and 20 mL of CHCl was added 3 , after the reaction product was completely dissolved, it was added dropwise into glacial ether for precipitation, and the above operation was repeated three times. Finally, the product was dried in a vacuum oven at 25°C for 48 hours to obtain the d...

Embodiment 3

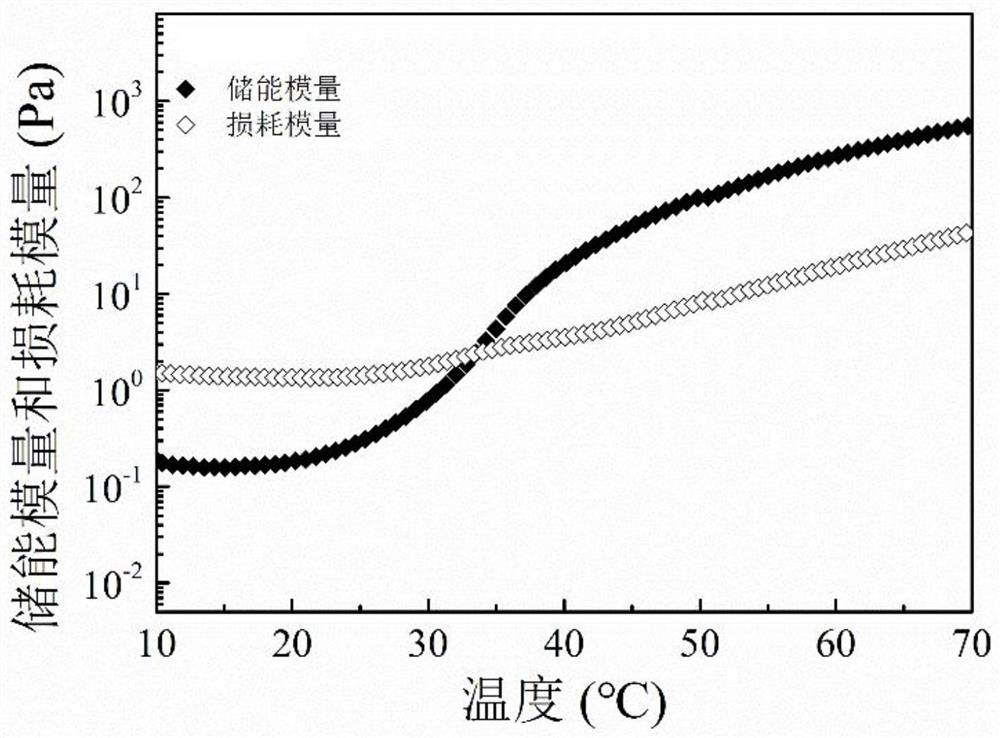

[0041] First, 0.500g (0.25mmol) of PEG of diamino 2000 Remove water azeotropically with 50 mL of toluene until the remaining solvent volume is 5 mL, seal the system and cool to room temperature. 0.321g (2.80mmol) L-alanine-N-carboxyl anhydride (L-Ala-NCA) and 0.178g (0.93mmol) L-phenylalanine-N-carboxyl anhydride (L-Phe -NCA) monomer was added to 20 mL of CHCl dried over anhydrous magnesium sulfate 3 / DMF (v / v 3:1) mixed solvent, and magnetically stirred at room temperature for 30min. Under an atmosphere of argon, transfer the solution of mixed monomers to dry NH 2 -PEG 2000 -NH 2 Then, the temperature of the system was raised to 37° C., and the reaction was carried out under magnetic stirring for 3 days under an atmosphere of argon. The system was then cooled to room temperature, and 20 mL of CHCl was added 3 , after the reaction product was completely dissolved, it was added dropwise into glacial ether for precipitation, and the above operation was repeated three times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com