Preparation method of polylactic acid-coated naringenin and starch-loaded silver composite nanoparticles

A composite nanoparticle and nanoparticle technology, which is applied in the field of preparation of polylactic acid-coated naringenin and starch-loaded silver composite nanoparticles, can solve the problems of low drug loading and encapsulation efficiency, long preparation process, etc., and achieve Long-acting sustained release, shortening the preparation process, and improving the effect of drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

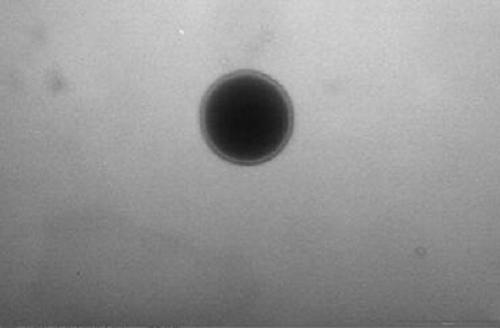

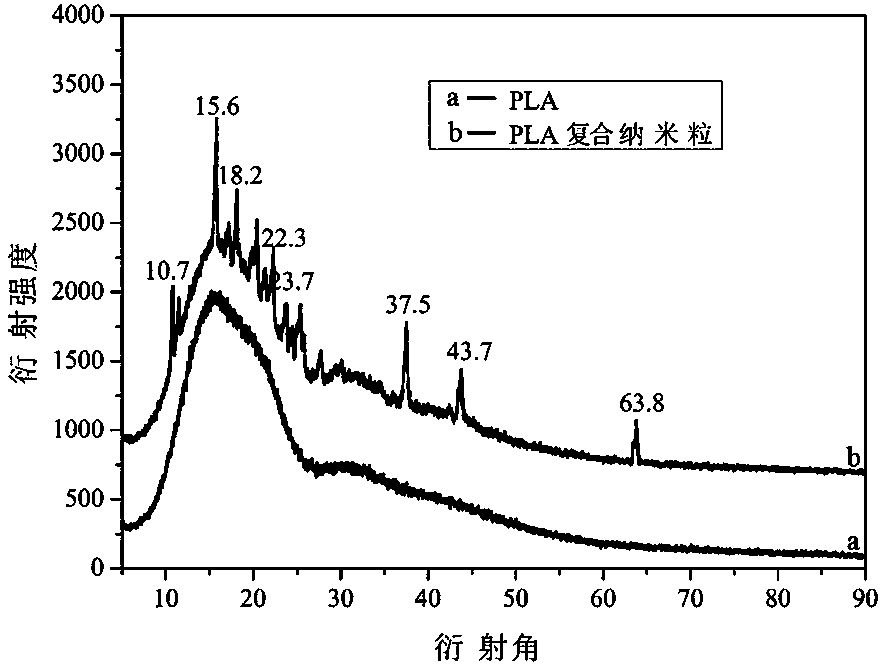

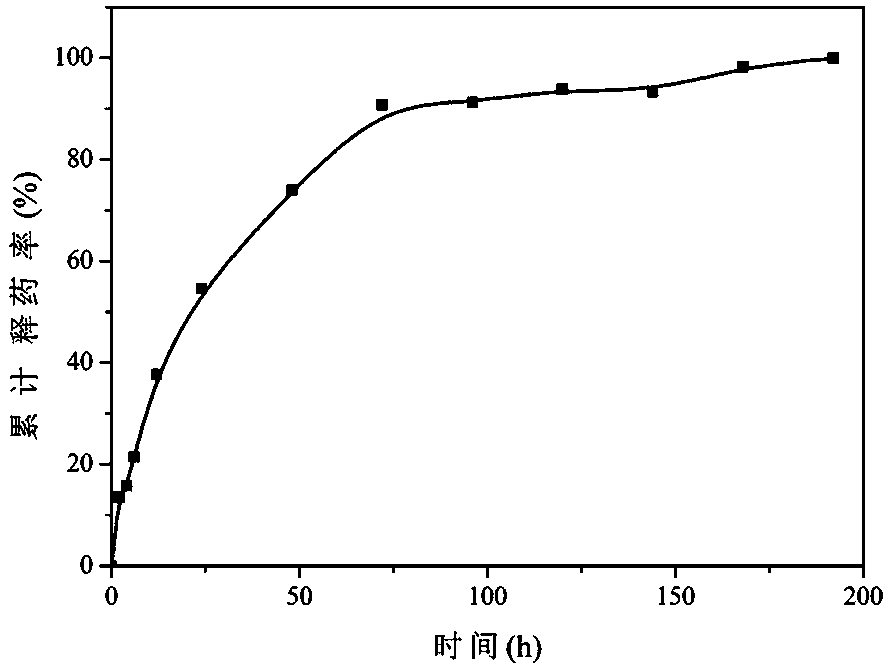

Image

Examples

preparation example Construction

[0027] (1) Preparation of homogeneous suspension

[0028] Weighed 10 mg of dried starch-loaded silver nanoparticles and 10–50 mg of naringenin in 10 mL of ultrapure water, and dispersed them uniformly with an ultrasonic disperser at 300–600 W in an ice-water bath. form a homogeneous suspension;

[0029] (2) Preparation of composite nanoparticles

[0030] Weigh 100-300 mg of polylactic acid, stir and dissolve it in 20-30 mL of acetone, and make a mass concentration of 0.005-0.015 g·mL -1 The solution, the homogeneous suspension obtained in (1) was added dropwise to the polylactic acid acetone solution, and at the same time placed in a high-shear dispersing emulsifier at 3000 r min -1 After 30-60 min, 20-45 mL of ethanol was added dropwise to precipitate polylactic acid-coated naringenin and starch-loaded silver composite nanoparticles;

[0031] (3) Separation of composite nanoparticles

[0032] Add 20 mL of an aqueous solution of a stabilizer with a mass fraction of 0.1% to...

Embodiment 1

[0040] The preparation method of polylactic acid coated naringenin and starch silver-loaded composite nanoparticles comprises the following steps:

[0041] ① Add 0.5 g of soluble starch and 50 mL of ultrapure water into a beaker, heat the above solution to 90 °C, and place it under a stirrer until the starch is completely dissolved, then gradually cool it to 70 °C at room temperature; then put 1 The concentration in mL is 0.1 mol·L -1 The silver nitrate solution was added to the soluble starch solution, and after 10 min, 2.5 mL of 0.1 mol·L -1 Glucose solution, then drop an appropriate amount of 0.5% sodium hydroxide solution or ammonia water, adjust the pH value of the reaction solution to about 8.0, and continue stirring under this condition for 120 min; -1 centrifuged, washed three times with ultrapure water, vacuum-freezed and dried to obtain brown-red starch-loaded silver nanoparticles;

[0042] (1) Preparation of homogeneous suspension

[0043] 10 mg of dried starch-l...

Embodiment 2

[0049] The preparation method of polylactic acid coated naringenin and starch silver-loaded composite nanoparticles comprises the following steps:

[0050] ① Add 0.5 g of soluble starch and 50 mL of ultrapure water into a beaker, heat the above solution to 90 °C, and place it under a stirrer until the starch is completely dissolved, then gradually cool it to 70 °C at room temperature; then put 1 The concentration in mL is 0.1 mol·L -1 The silver nitrate solution was added to the soluble starch solution. After 10 min, 2.5 mL glucose solution with a concentration of 0.1 mol·L-1 was added to the above mixed solution, and then an appropriate amount of sodium hydroxide solution with a concentration of 0.5% or Ammonia, adjust the pH value of the reaction solution to about 8.0, and keep stirring under this condition for 120 min; -1 centrifuged, washed three times with ultrapure water, vacuum-freezed and dried to obtain brown-red starch-loaded silver nanoparticles;

[0051] (1) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com