Titanium alloy cast ingot and preparation method thereof

A technology of titanium alloy and ingot casting, which is applied in the field of titanium alloy ingot casting and its preparation, and can solve the problems of deteriorating heat dissipation conditions of ingot casting, rising production costs, and unsatisfactory edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] An embodiment of the present invention provides a method for preparing a titanium alloy, which includes the following steps S10-S20.

[0049] Step S10 , pressing the raw material of the titanium alloy ingot by electrodes and then welding to produce a consumable electrode; the consumable electrode contains segregated elements.

[0050] Step S20, subjecting the consumable electrode prepared in step S10 to multiple times of vacuum consumable melting to obtain a titanium alloy ingot.

[0051] Among them, the steps of the last vacuum self-consumption smelting include the arc-starting smelting stage, the stable smelting stage and the feeding stage;

[0052] In the arc-starting smelting stage, first use a current of 3kA-6kA to strike the arc, then increase the melting current to the first current value within 1min-15min, and start arc-starting smelting for 5-30min; the first current value is 15kA-30kA.

[0053] In the stable smelting stage, reduce the smelting current to the ...

Embodiment 1

[0106] (1) According to the composition requirements of TC17 titanium alloy ingot in GB / T 3620.1, weigh the sponge titanium, aluminum-molybdenum master alloy, aluminum bean, sponge zirconium, metal chromium, titanium-tin master alloy that meet the requirements of the national standard, and mix After the batching system is mixed, it is pressed into an electrode block by an 8,000-ton hydraulic press, and welded into a Φ420mm cylindrical consumable electrode in a vacuum plasma welding box. The pressure used for pressing is 300Mpa-400Mpa.

[0107] (2) The consumable electrode obtained in step (1) is used for the first vacuum consumable smelting in a Ф500mm crucible to obtain an ingot. The parameters are: first use 2-4kA current to strike the arc, and keep it for 2 minutes. After the arc is successfully struck, increase the melting current to 14-16kA within 6 minutes, and start the arc to melt for 20 minutes; then reduce the melting current to 13-10 minutes within 10 minutes. 15kA...

Embodiment 2

[0117] Example 2 is basically the same as Example 1, except that the parameters of the arc-starting smelting stage of the third vacuum self-consumable smelting in step (4) are as follows: first use 3kA to 5kA current to start the arc, keep it for 2min, and successfully After arc ignition, increase the melting current to 26kA~28kA within 12 minutes, and start arc melting for 20 minutes; then reduce the melting current to 11kA~13kA within 25 minutes, and control the vacuum degree below 1.33Pa, and the melting voltage is 26V~28V. The arc current is 6A ~ 10A, and the melting is carried out stably. When the weight of the remaining unmelted consumable electrodes is 140Kg, it starts to enter the feeding stage, and the melting current gradually decreases. Other steps and parameters are the same as in Example 1.

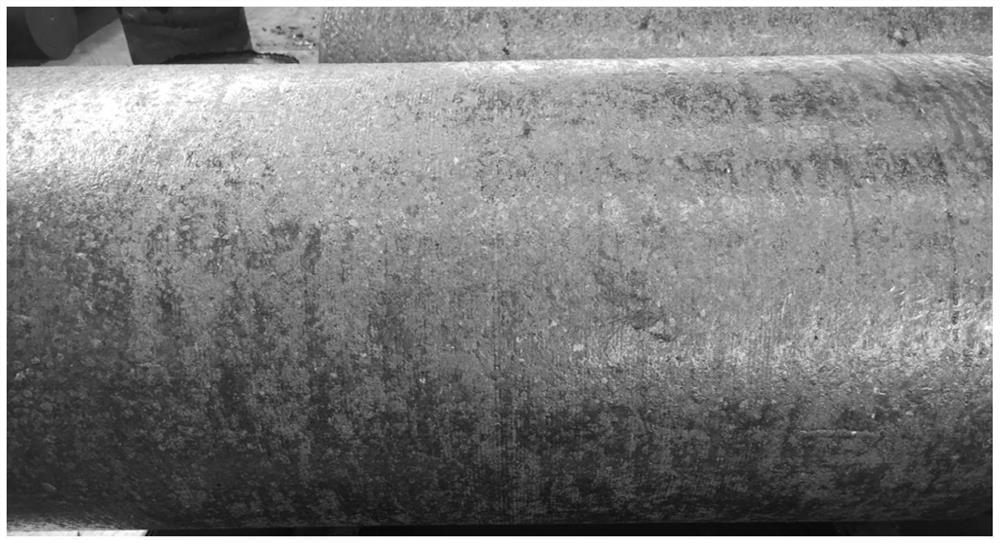

[0118] The physical photograph of the titanium alloy ingot that present embodiment 2 makes is as figure 2 As shown, the surface is bright silver-white, without obvious surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com