Nuclear parent substituted naphthalimide electrochemical polymerization monomer and preparation method thereof

A kind of technology of naphthalenediimide and naphthalenediimide mother, which is applied in the field of electrochemical polymerization monomer of naphthalenediimide substituted by mother nucleus and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

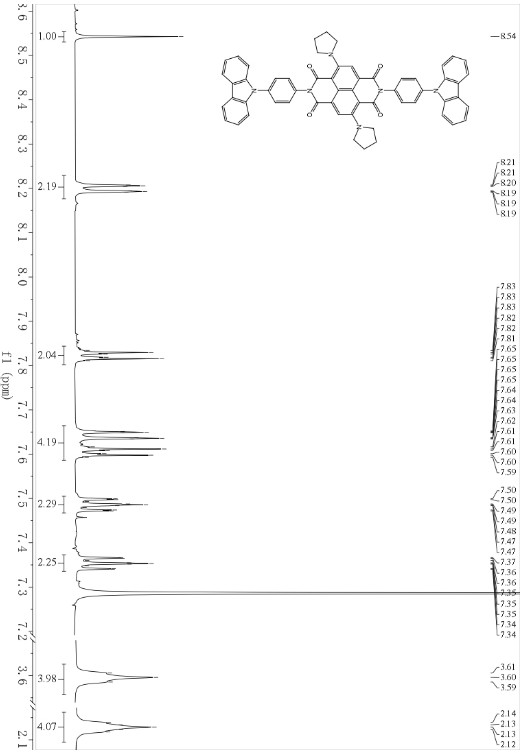

Image

Examples

Embodiment 1

[0037] Synthesis of compound PNDI-Cz:

[0038]A mixture of PNDI (0.5 g, 1.2 mmol), Cz-E284 (3.6 g, 12.4 mmol), anhydrous copper acetate (2.2 g, 12.4 mmol), well-dried molecular sieves (4 Å) and anhydrous N,N-di A suspension of methylacetamide (50 mL) was continuously sparged with oxygen for 30 min, then triethylamine (1.7 mL, 12.4 mmol) was added to the suspension and the resulting reaction mixture was stirred at 55 °C under an oxygen atmosphere for 2 days . During this period, it is necessary to ensure that the oxygen content of the system is sufficient to ensure the smooth progress of the reaction. Then additional Cz-E284 (1.8 g, 6.2 mmol), anhydrous copper acetate (1.1 g, 6.2 mmol) and triethylamine (0.9 mL, 6.2 mmol) in N,N-dimethylacetamide (15 mL ) solution was added to the reaction mixture, which was stirred for another 3 days at 55 °C under an oxygen atmosphere. After 5 days, the reaction mixture was cooled to room temperature, washed with a small amount of DMF, fol...

Embodiment 2

[0041] Synthesis of compound PNDI-TPA:

[0042] A mixture of PNDI (0.5 g, 1.2 mmol), TPA-E284 (3.6 g, 12.4 mmol), anhydrous copper acetate (2.2 g, 12.4 mmol), well-dried molecular sieves (4 Å) and anhydrous N,N-dimethyl A suspension of acetamide (50 mL) was continuously sparged with oxygen for 30 min, then triethylamine (1.7 mL, 12.4 mmol) was added to the suspension and the resulting reaction mixture was stirred at 55 °C under an oxygen atmosphere for 2 days. During this period, it is necessary to ensure that the oxygen content of the system is sufficient to ensure the smooth progress of the reaction. Then additional amounts of TPA-E284 (1.8 g, 6.2 mmol), copper acetate (1.1 g, 6.2 mmol) and triethylamine (0.9 ml, 6.2 mmol) in N,N-dimethylacetamide (15 ml) solution was added to the reaction mixture, at O 2 Stir at ambient for an additional 3 days at 55°C. After 5 days, the reaction mixture was cooled to room temperature and washed with CH 2 Cl 2 (100 mL) for washing. Af...

Embodiment 3

[0045] Synthesis of compound PNDI-2CZ:

[0046] A mixture of PNDI (0.5 g, 1.2 mmol), 2Cz-E284 (5.6 g, 12.4 mmol), anhydrous copper acetate (2.2 g, 12.4 mmol), well-dried molecular sieves (4 Å) and anhydrous N,N-dimethyl A suspension of acetamide (50 mL) was continuously sparged with oxygen for 30 min, then triethylamine (1.7 mL, 12.4 mmol) was added to the suspension and the resulting reaction mixture was stirred at 55 °C under an oxygen atmosphere for 2 days. During this period, it is necessary to ensure that the oxygen content of the system is sufficient to ensure the smooth progress of the reaction. Then an additional amount of 2Cz-E284 (2.8 g, 6.2 mmol), copper acetate (1.1 g, 6.2 mmol) and triethylamine (0.9 ml, 6.2 mmol) in N,N-dimethylacetamide (25 ml) solution was added to the reaction mixture, at O 2 Stir at ambient for an additional 3 days at 55°C. After 5 days, the reaction mixture was cooled to room temperature and washed with CH 2 Cl 2 (100 mL) for washing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com