Impregnation slurry and preparation method thereof

A technology of slurry and wet ball milling, which is applied in the field of preparation of ceramic matrix composite materials to achieve the effect of improving ablation resistance, efficiency and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

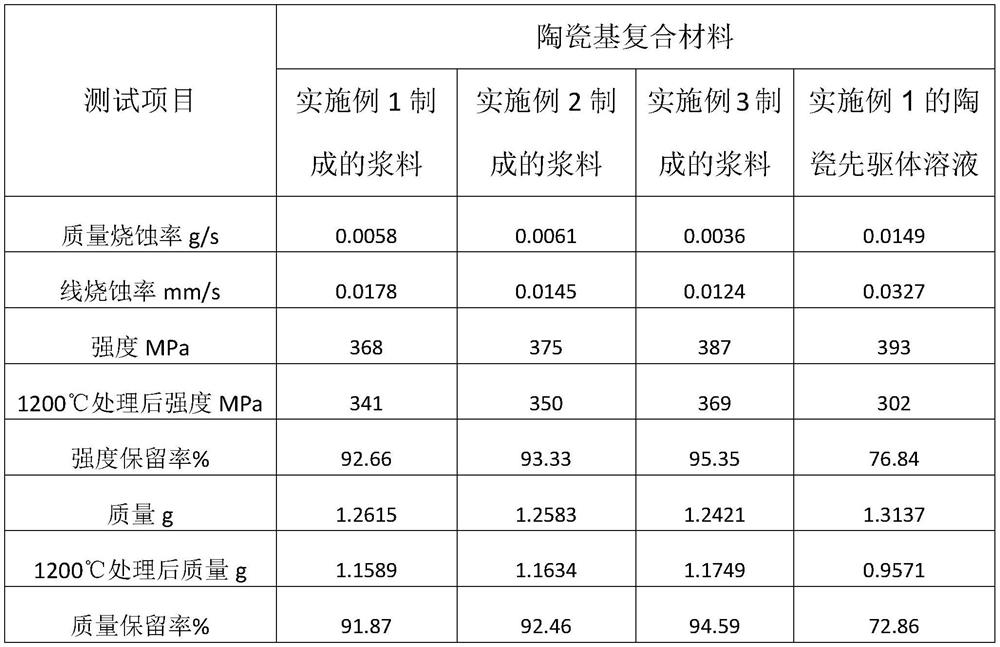

Examples

preparation example Construction

[0028] A preparation method for dipping slurry, comprising the following steps:

[0029] ① The ceramic powder Si 3 N 4 , SiC, ZrB 2 , ZrC, H f C.H f B 2 , BN and B 4 One or more components in C are slowly poured into the alumina ball milling jar in sequence, distilled water is added, and zirconium balls are put in as the ball milling medium, wherein, raw materials (ceramic powder containing anti-ablation components), grinding balls, The water mass ratio is 2~4:5~9:2~4; place the ball mill jar in a planetary ball mill, grind at a speed of 400~600r / min for 4~8h, screen out the ball milling medium, put it in a drying oven at 100 Dry the mixed powder at ~120°C for 4-8 hours; collect the dried mixed powder in an agate mortar and grind for 1-2 hours, and then pass through a 100-mesh sieve to obtain a uniformly mixed ceramic powder;

[0030] ② After the ceramic precursor is pulverized, it is slowly dissolved into one or more organic solvents such as xylene, cyclohexane, diviny...

Embodiment 1

[0034] ① ZrB 2 The ceramic powder is slowly poured into an alumina ball mill jar, distilled water is added, and zirconium balls are put in as a ball mill medium, wherein the raw material (ZrB 2 Ceramic powder), grinding balls, and water mass ratio of 3:8:2; put the ball mill jar in a planetary ball mill, grind at a speed of 600r / min for 6h, sieve out the ball milling medium, and put it in a drying oven to dry at 110°C Mix the powder uniformly for 8 hours; collect the dry mixed powder in an agate mortar and grind for 1 hour, and then pass through a 100-mesh sieve to obtain ZrB 2 Ultrafine ceramic powder;

[0035] ② After the polycarbosilane is pulverized, it is slowly dissolved in xylene, the dissolution temperature is 40°C, and the heating method is a water bath to form a ceramic precursor solution (viscosity is 120mPa·s);

[0036] ③The ceramic precursor solution in step ②, the ZrB in step ① 2 The ultra-fine ceramic powders are successively loaded into the alumina ball mill...

Embodiment 2

[0039]① Slowly pour the ZrC ceramic powder into an alumina ball mill jar, add distilled water, and put in zirconium balls as the ball milling medium, wherein the mass ratio of raw material (ZrC ceramic powder), grinding balls, and water is 3:8:2; Put the ball mill jar in a planetary ball mill, grind at a speed of 600r / min for 6h, sieve out the ball milling medium, put it in a drying oven and dry the mixed powder at 110°C for 8h; collect the dried mixed powder in an agate mortar Grind for 1 hour, then pass through a 100-mesh sieve to obtain ZrC ultrafine ceramic powder;

[0040] ② After the polycarbosilane is pulverized, it is slowly dissolved in xylene, the dissolution temperature is 40°C, and the heating method is a water bath to form a ceramic precursor solution (viscosity is 120mPa·s);

[0041] ③Put the ceramic precursor solution in step ② and the ZrC ultrafine ceramic powder in step ① into an alumina ball milling tank in turn, wherein the ceramic precursor solution is 95wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com