Glass powder for electronic paste and preparation method thereof

A technology of electronic paste and glass powder, which is applied in the field of glass powder for electronic paste and its preparation, which can solve the problems of increased melting temperature and softening temperature, decreased chemical stability and wettability, and mismatched expansion coefficients. , to achieve the effects of lower melting temperature, improved chemical stability and wettability, and increased expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

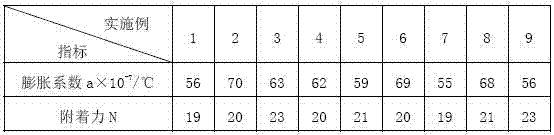

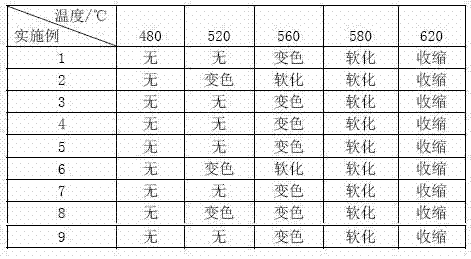

Examples

Embodiment 1

[0029] The preparation method of the glass powder for the electronic paste of the present embodiment is as follows:

[0030] S1. Weigh 7.2g SiO with an electronic platform scale 2 , 0.9g Al 2 o 3 , 0.9g MgO, put into ceramic mortar and grind, mix;

[0031] S2. Weigh 231g Bi respectively 2 o 3 , 9g ZnO, 48g B 2 o 3, together with the mixed material powder obtained in step S1, put into a stainless steel basin with a capacity of 5L and mix;

[0032] S3. Move the mixed initial material obtained in step S2 into a ceramic crucible with a capacity of 200ml, put it into a muffle furnace, and melt it at 1050°C for 10 minutes, then take out the molten glass and pour it into pure glass at room temperature (about 25°C). Water quenching is carried out in water, and the product after water quenching is collected and dried in an oven at 90°C for 5 hours;

[0033] S4. The material obtained in step S3 is rolled into granules with a twin-roll mill, and then ball milled for 30min at a sp...

Embodiment 2

[0037] The preparation method of the glass powder for the electronic paste of the present embodiment is as follows:

[0038] S1. Weigh 7.2g SiO with an electronic platform scale 2 , 0.9g Al 2 o 3 , 0.9g MgO, put into ceramic mortar and grind, mix;

[0039] S2. Weigh 231g Bi respectively 2 o 3 , 15g ZnO, 42g B 2 o 3 , together with the mixed material powder obtained in step S1, put into a stainless steel basin with a capacity of 5L and mix;

[0040] S3. Move the mixed initial material obtained in step S2 into a ceramic crucible with a capacity of 200ml, put it into a muffle furnace, and melt it at 1040°C for 10 minutes, then take out the molten glass and pour it into pure glass at room temperature (about 25°C). Water quenching is carried out in water, and the product after water quenching is collected and dried in an oven at 90°C for 5 hours;

[0041] S4. The material obtained in step S3 is rolled into granules with a twin-roll mill, and then ball milled for 30min at a ...

Embodiment 3

[0045] The preparation method of the glass powder for the electronic paste of the present embodiment is as follows:

[0046] S1. Weigh 7.2g SiO with an electronic platform scale 2 , 0.9g Al 2 o 3 , 0.9g MgO, put into ceramic mortar and grind, mix;

[0047] S2. Weigh 231g Bi respectively 2 o 3 , 21g ZnO, 39g B 2 o 3 , together with the mixed material powder obtained in step S1, put into a stainless steel basin with a capacity of 5L and mix;

[0048] S3. Move the mixed initial material obtained in step S2 into a ceramic crucible with a capacity of 200ml, put it into a muffle furnace, and melt it at 1030°C for 18 minutes, then take out the molten glass and pour it into pure glass at room temperature (about 25°C). Water quenching is carried out in water, and the product after water quenching is collected and dried in an oven at 90°C for 5 hours;

[0049] S4. The material obtained in step S3 is rolled into granules with a twin-roll mill, and then ball milled for 30min at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com