Preparation method of high-density fine-grain W-TiC alloy material

An alloy material and fine-grained technology, which is applied in the field of preparation of high-density fine-grained W-TiC alloy materials, can solve the problems of unsatisfactory material performance, low material density, and difficulty in sintering densification, etc., and achieve fast heating speed , Short sintering time, avoid serious effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

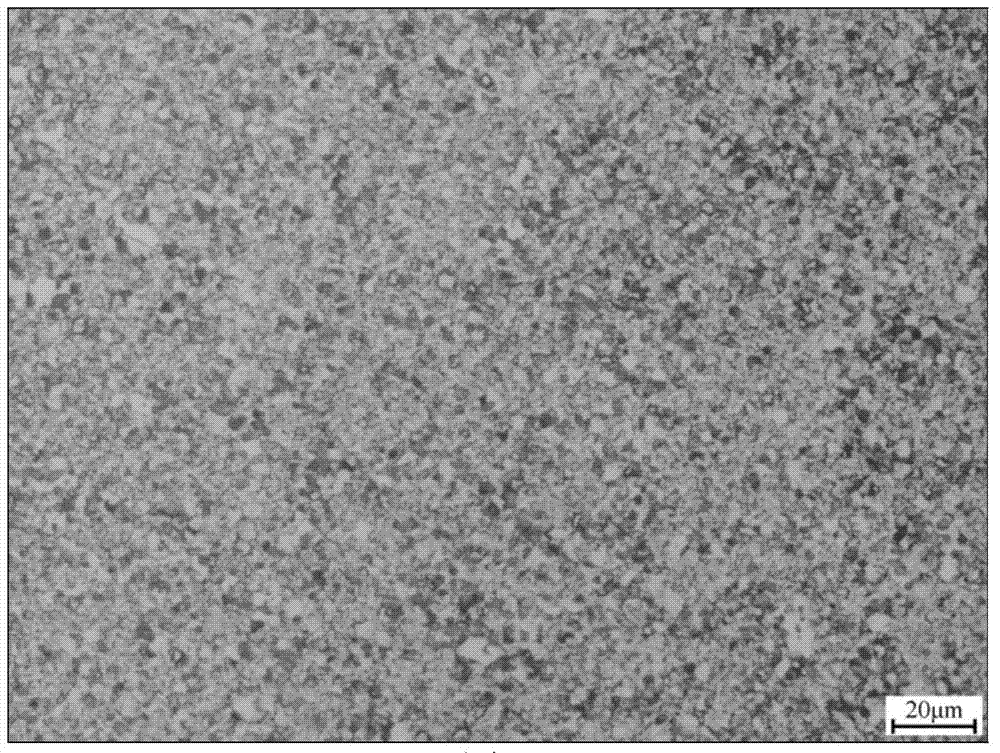

Embodiment 1

[0029] The preparation of the W-TiC alloy material of this embodiment:

[0030] Step 1. Using the method of wet high-energy ball milling, mix W powder with mass purity not less than 99.9% and average particle size not greater than 2 μm and TiC powder with mass purity not less than 99.9% and average particle size not greater than 100 nm by ball milling. The specific process is as follows:

[0031] Step 101. Weigh 3g of TiC powder and 2997g W powder, then take by weighing 7500g absolute ethanol according to solid-liquid ratio 1: 2.5;

[0032] Step 102, add 3g of TiC powder, 299.7g of W powder and 7500g of absolute ethanol into a high-energy ball mill, and ball mill for 30 hours at a speed of 3000r / min;

[0033] Step 103, adding 1498.5 g of W powder into a high-energy ball mill, and ball milling for 30 hours at a speed of 3000 r / min;

[0034] Step 104, add the remaining 1198.8g of W powder into the high-energy ball mill, and ball mill for 88 hours at a speed of 3000r / min;

[0...

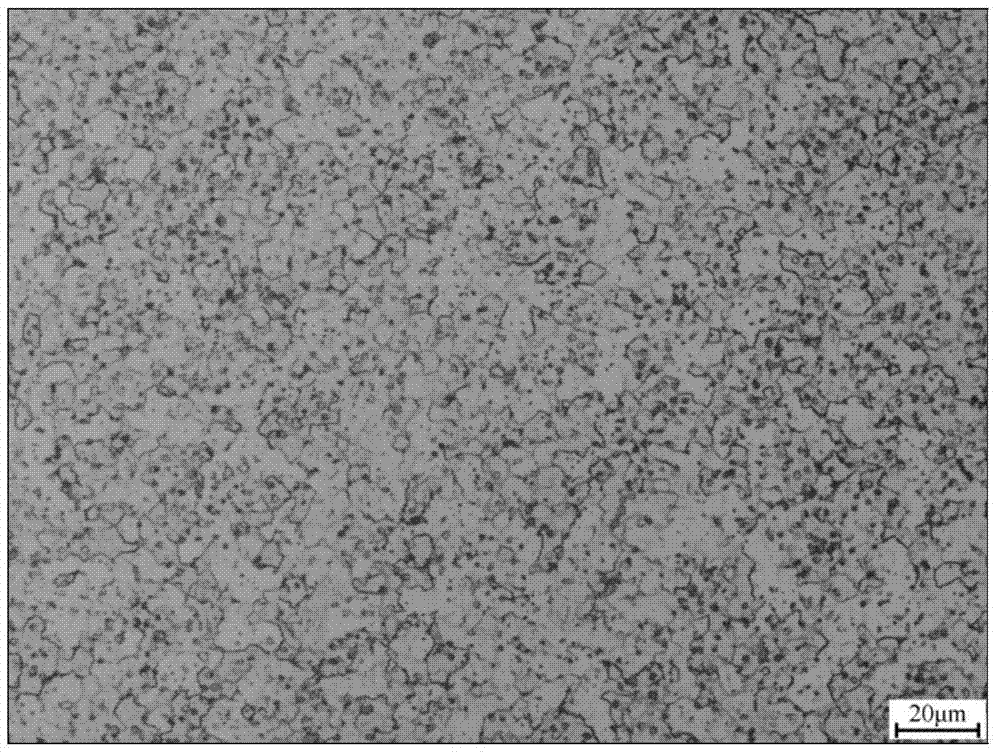

Embodiment 2

[0040] The preparation of the W-TiC alloy material of this embodiment:

[0041] Step 1. Using the method of wet high-energy ball milling, mix W powder with mass purity not less than 99.9% and average particle size not greater than 2 μm and TiC powder with mass purity not less than 99.9% and average particle size not greater than 100 nm by ball milling. The specific process is as follows:

[0042] Step 101. Weigh 15g of TiC powder and 2985g W powder, then take by weighing 6000g acetone according to solid-liquid ratio 1: 2;

[0043] Step 102, adding 15g of TiC powder, 298.5g of W powder and 6000g of acetone into a high-energy ball mill, and ball milling for 36 hours at a speed of 2500r / min;

[0044] Step 103, adding 1492.5 g of W powder into a high-energy ball mill, and ball milling for 36 hours at a speed of 2500 r / min;

[0045] Step 104, adding the remaining 1194g of W powder into the high-energy ball mill, and ball milling for 120h at a speed of 2500r / min;

[0046] Then pl...

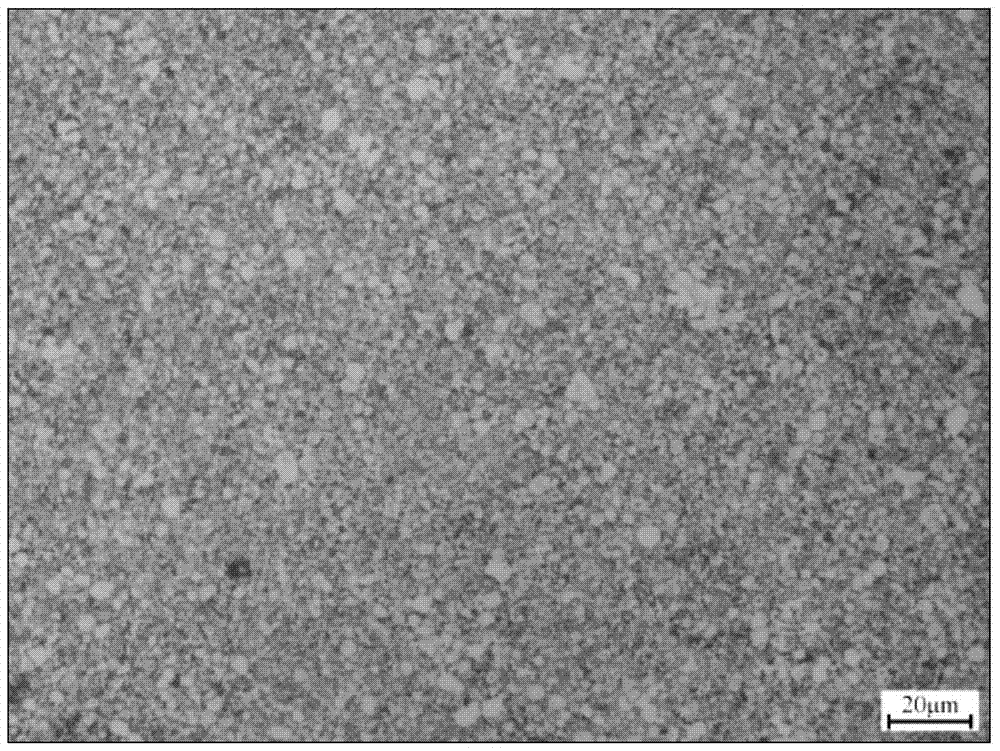

Embodiment 3

[0051] The preparation of the W-TiC alloy material of this embodiment:

[0052] Step 1. Using the method of wet high-energy ball milling, mix W powder with mass purity not less than 99.9% and average particle size not greater than 2 μm and TiC powder with mass purity not less than 99.9% and average particle size not greater than 100 nm by ball milling. The specific process is as follows:

[0053] Step 101. Weigh 30g TiC powder and 2970g W powder, then weigh 9000g of absolute ethanol according to the solid-to-liquid ratio of 1:3;

[0054] Step 102, add 30g of TiC powder, 297g of W powder and 9000g of absolute ethanol into a high-energy ball mill, and ball mill for 24 hours at a speed of 3500r / min;

[0055] Step 103, adding 1485g of W powder into a high-energy ball mill, and ball milling for 24 hours at a speed of 3500r / min;

[0056] Step 104, adding the remaining 1188g of W powder into the high-energy ball mill, and ball milling for 76 hours at a speed of 3500r / min;

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com