Method for preparing lithium manganate electrode material based on EMD, lithium manganate electrode material and application of lithium manganate electrode material

An electrode material, lithium manganate technology, applied in manganate/permanganate, positive electrode, battery electrode, etc., can solve the problems of high energy consumption, complex process steps, long reaction period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

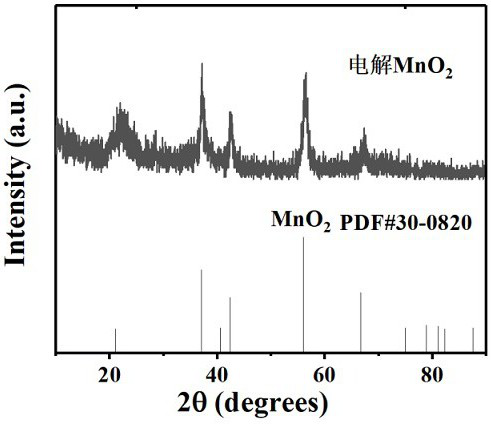

[0028] Raw materials: 1. Electrolytic manganese dioxide (EMD), manufacturer: Hunan Shunlong New Energy. 2. Battery grade lithium hydroxide monohydrate, manufacturer: Sichuan Xingsheng Lithium Industry. 3. Anhydrous ethanol, manufacturer: Henan Tianguan. 4. Butanol, manufacturer: Henan Tianguan.

[0029] Equipment: 1. XQM-10A planetary ball mill, manufacturer: Changsha Tianchuang Powder. 2. SDMF300 muffle furnace, manufacturer: Hunan Sande Technology.

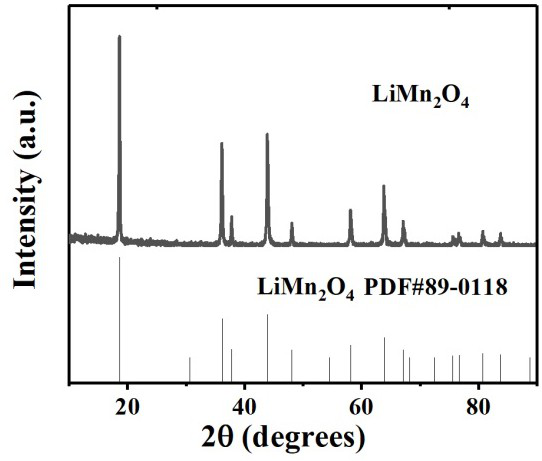

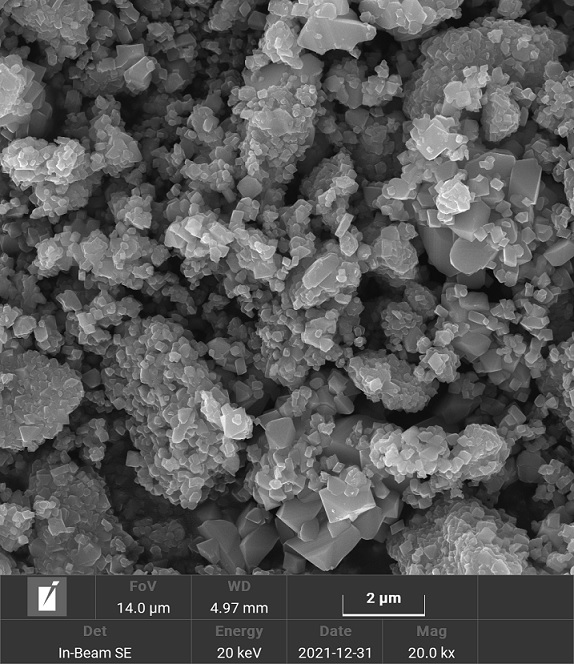

[0030] 1. Preparation of lithium manganate electrode material.

[0031] 1. Ball milling: Weigh 87g (1 mol) of electrolytic manganese dioxide (EDM), weigh lithium hydroxide monohydrate (LiOH·H 2 O) 21g (0.5mol), weigh 120ml of mixed alcohol (including 90ml ethanol and 30ml n-butanol). Pour EDM, lithium hydroxide monohydrate and mixed alcohol into the ball mill tank of the planetary ball mill, add zirconium beads, the ball-to-material ratio is about 4:1, seal and compact and ball mill at a speed of 150 r / min, and monitor duri...

Embodiment 2

[0043] The raw materials and equipment used in this example are the same as those in Example 1, and will not be repeated here. The main difference between this example and Example 1 is that the ratio of ethanol and n-butanol in the mixed alcohol used is slightly different. Similar to Example 1, the process of preparing lithium manganate electrode material in this example also includes the following steps:

[0044] 1. Ball milling: Weigh 87g (1 mol) of electrolytic manganese dioxide (EDM), weigh lithium hydroxide monohydrate (LiOH·H 2 O) 21g (0.5mol), weigh 120ml of mixed alcohol (including 96ml of ethanol and 24ml of n-butanol). Pour EDM, lithium hydroxide monohydrate and mixed alcohol into the ball mill tank of the planetary ball mill, add zirconium beads, the ball-to-material ratio is about 4:1, seal and compact and ball mill at a speed of 150 r / min, and monitor during the milling process Tank wall temperature, when the tank wall temperature reaches above 80°C, continue ba...

Embodiment 3

[0048] The raw materials used in this embodiment and equipment are identical with embodiment 1. The main difference between this example and Example 1 is that the ratio of ethanol and n-butanol in the mixed alcohol used is slightly different. The process of preparing lithium manganate electrode material in this embodiment also includes the following steps:

[0049] 1. Ball milling: Weigh 87g (1 mol) of electrolytic manganese dioxide (EDM), weigh lithium hydroxide monohydrate (LiOH·H 2 O) 21g (0.5mol), weigh 120ml of mixed alcohol (containing 100ml ethanol and 20ml n-butanol). Pour EDM, lithium hydroxide monohydrate and mixed alcohol into the ball mill tank of the planetary ball mill, add zirconium beads, the ball-to-material ratio is about 4:1, seal and compact and ball mill at a speed of 150 r / min, and monitor during the milling process Tank wall temperature, when the tank wall temperature reaches above 80°C, continue ball milling for 1 hour, during which the tank wall temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com