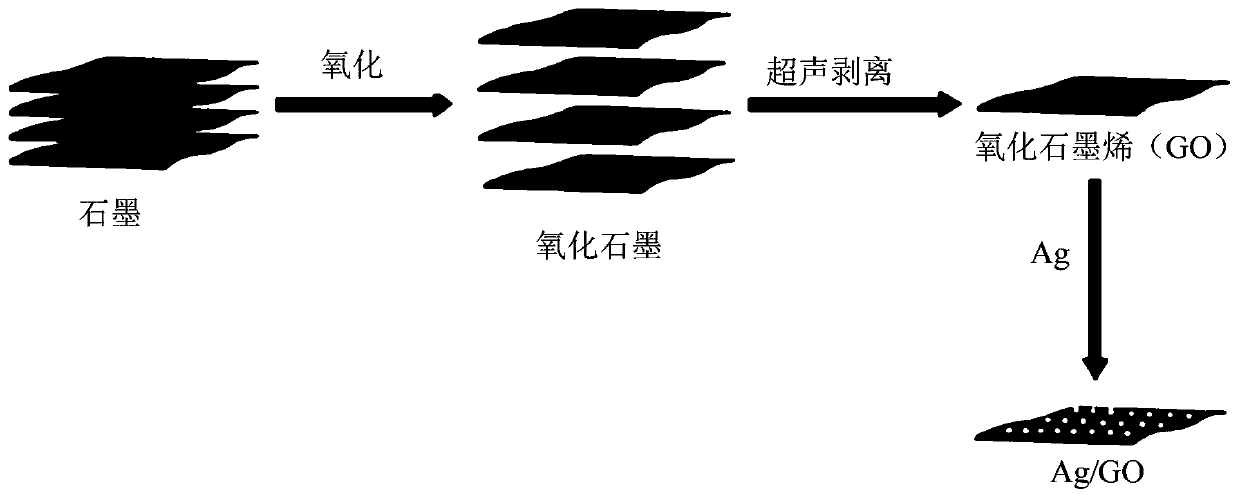

Preparation method of Ag/GO photocatalytic material for sterilization

A photocatalytic material and graphene technology, which is applied in the preparation field of Ag/GO photocatalytic materials, can solve problems such as poor photocatalytic performance, and achieve the effects of simple preparation method, broadening the spectral response range, and improving photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0016] S1, using the Hummers method to prepare graphene or GO with graphite powder;

[0017] S2, 1.08g graphene with nanosheet structure and 0.85g AgNO 3 Grind and mix with a mortar;

[0018] S3. Put the mixture in a tube furnace, calcinate it under a nitrogen atmosphere at 500°C for 6 hours, and get a sample of 50% Ag / GO after natural cooling, 50% of which is the mass ratio of Ag nanoparticles and nanosheet graphene, and put it in a drying oven in spare.

Embodiment approach 2

[0020] S1, using the Hummers method to prepare graphene or GO with graphite powder;

[0021] S2, 2.16g graphene with nanosheet structure and 2.548g AgNO 3 Grind and mix with a mortar;

[0022] S3, the mixture is placed in a tube furnace, calcined at 500°C for 6h under a nitrogen atmosphere, and after natural cooling, a sample of 75% Ag / GO is obtained, 75% being the mass ratio of Ag nanoparticles to nanosheet graphene, and placed in a dry place Reserve in box.

Embodiment approach 3

[0024] S1, using the Hummers method to prepare graphene or GO with graphite powder;

[0025] S2, 4.32g graphene with nanosheet structure and 1.274g AgNO 3 Grind and mix with a mortar;

[0026] S3, the mixture is placed in a tube furnace, calcined at 500°C for 6h under a nitrogen atmosphere, and after natural cooling, the sample 19%Ag / GO is obtained, 19% is the mass ratio of Ag nanoparticles to nanosheet graphene, and placed in a dry place Reserve in box.

[0027] As a specific example, the preparation of graphene from graphite powder by the Hummers method in step S1 of the embodiments 1 to 3 specifically includes the following steps:

[0028] S11. Preparation of graphite oxide: assemble a 250mL reaction bottle in an ice-water bath, add 95% to 98% concentrated sulfuric acid, add a solid mixture of 2g graphite powder and 1g sodium nitrate under stirring, and then add 6g permanganate in portions Potassium, control the reaction temperature not to exceed 20°C, stir the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com