Synthetic method of hexafluorophosphate

A technology of hexafluorophosphate and synthesis method, applied in the field of synthesis of hexafluorophosphate, can solve the problems of difficulty in purification, storage, transportation and use of phosphorus pentafluoride, difficulty in large-scale industrial application, and high requirements on structure and material, To achieve the effect of rationalizing the separation sequence, simplifying the separation process, and improving the solvent recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

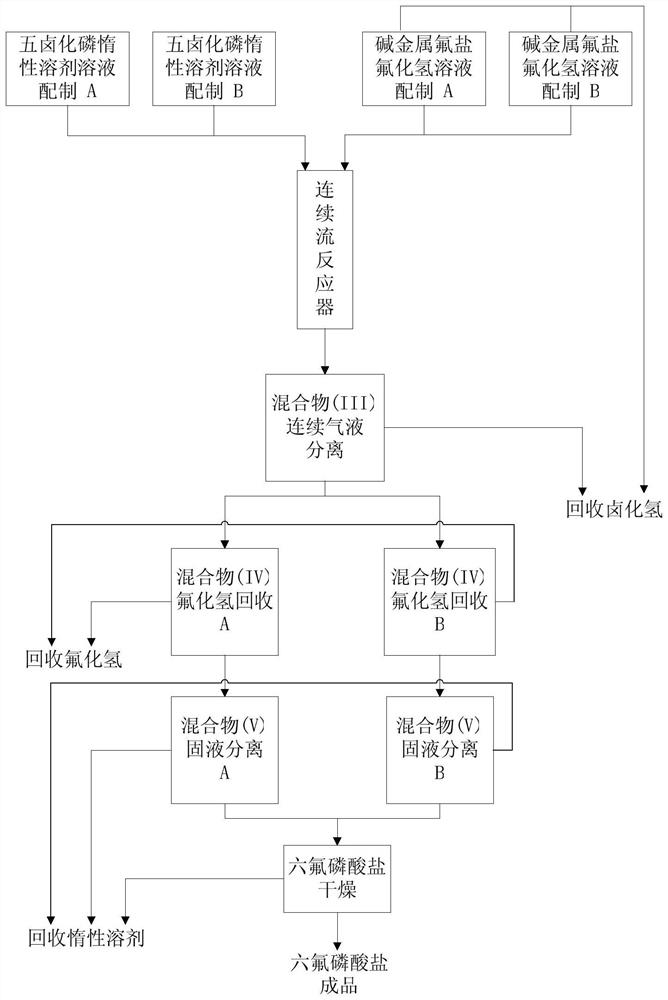

[0106] As a continuous reactor with a microreactor, a phosphorus, lithium chloride, hydrogen fluoride is a raw material, and a lithium hexafluorophosphate is synthesized by toluene is an inert organic solvent. figure 1 The synthesis process is as follows:

[0107] (1) The quantitative toluene is added to the formulating kettle of the phosphloride toluene solution, and the quantitative pentachloride solid is added under nitrogen protection, stir up to 60 to 65 ° C, after all dissolution, cool down to 20 ~ 25 ° C gave a high mass concentration of 25% pentachloride solution, and preservation was stored under nitrogen protection. The phosphonated phosphorne solution is divided into AB kettle, and the two are used.

[0108] (2), the quantitative water-free hydrogen fluoride liquid is added to the fluorinated hydrogen fluoride solution formulation, nitrogen protection, temperature control - 10 ~ -5 ° C, slowly add quantitative lithium chloride solid, stirred and dissolved, resulting in ...

Embodiment 2

[0117] As a continuous reactor with a microreactor, phosphorus phosphorus, sodium fluoride, hydrogen fluoride is a raw material, and the sodium hexafluorophosphate is synthesized by chlorofluorine. figure 1 The synthesis process is as follows:

[0118] (1), the quantitative chlorobenzene is added to the formulation of the phosphrachloride chloride solution. Under nitrogen protection, the quantitative pentachloride solid is added, and the stirring is warmed to 50 to 55 ° C, and after all of the solid is all dissolved, it will cool down. 10 ~ 15 ° C, resulting in a hydrochloride chloride solution having a mass concentration of 20%, and is preserved under nitrogen protection. The phosphrachloride chloride chlorobenzene solution is divided into AB kettle, two kette crossings.

[0119] (2), the quantitative water-free hydrogen fluoride liquid is added to the fluorinated sodium fluoride solution formulation, nitrogen protection, temperature control 10 ~ 15 ° C, slowly add quantitative f...

Embodiment 3

[0128] As a continuous reactor with a microreactor, a phosphorus, potassium chloride, hydrogen fluoride is a raw material, and the potassium organic solvent, the synthesis of hexafluoro phosphate, and the process flow is combined. figure 1 The synthesis process is as follows:

[0129] (1), the quantitative chloroform is added to the formulating kettle with a pentachloride chloride. Under nitrogen protection, a quantitative pentachloride solid is added, and the stirring is warmed to 40 to 45 ° C, and after all of the solid is dissolved, it will cool down to 20 ~ 25 ° C, the mass concentration of 30% p-chloride chloride solution is preserved under nitrogen protection. Penthalchloride chloroform solution is divided into AB kettle, two altitude cross-use.

[0130] (2), the quantification of water-free hydrogen fluoride liquid is added to the fluorinated potassium hydrogen fluoride solution, nitrogen protection, temperature control - 15 ~ -10 ° C, slowly add quantitative sostatis solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com